Basic Info.

Model NO.

1060 1100 3003 5083 6061 8011

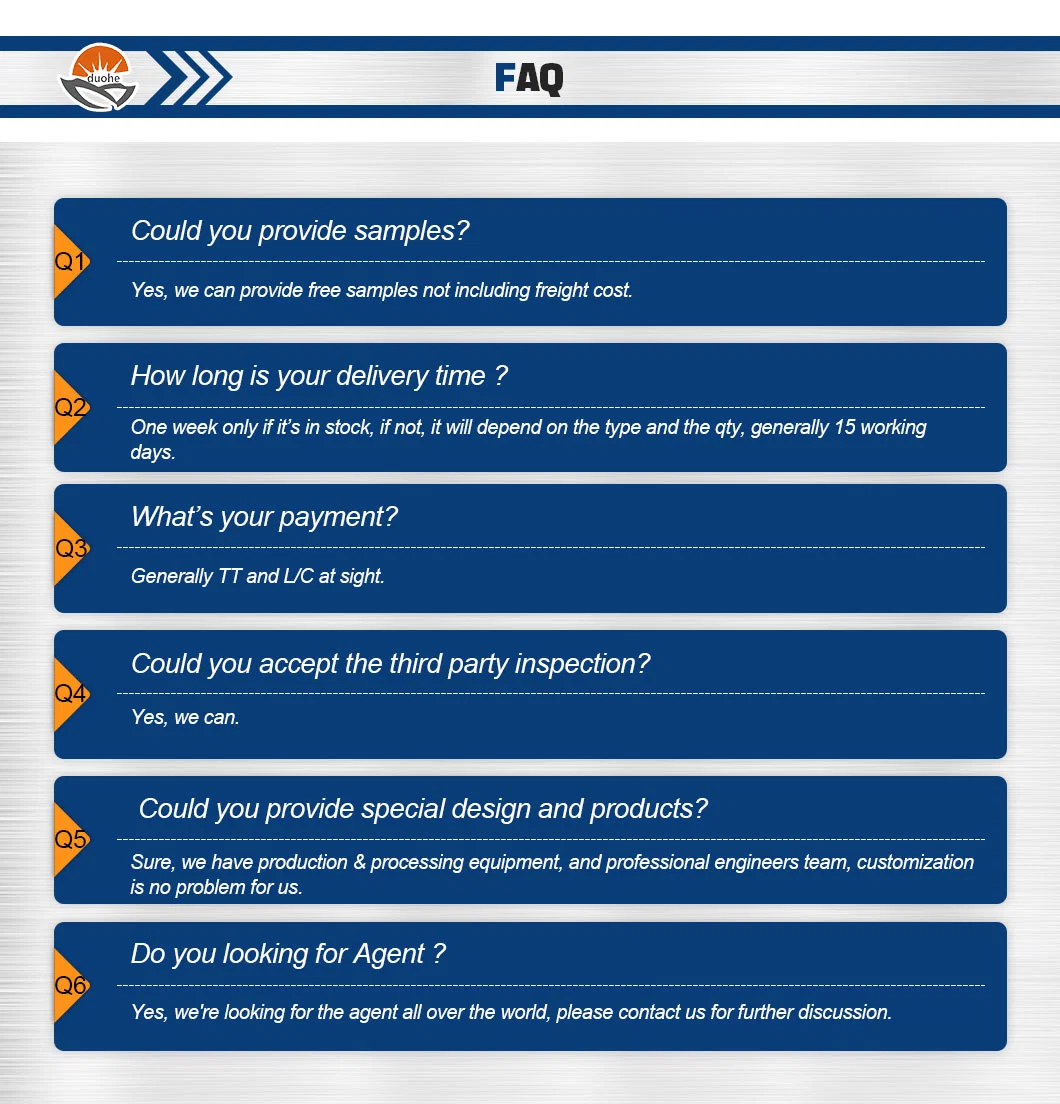

Samples

Available

Delivery Time

15-21 Days

Tolerance

+/-1%

Thickness

Customized

Transport Package

Standard Seaworthy Export Packing

Specification

customized

Trademark

Duohe

Origin

Shandong, China

HS Code

721823

Production Capacity

100, 000 Tons Per Year

Product Description

https://dhstainless.en.made-in-china.com/product-group/zohalMPZXuRk/Aluminum-Pipe-Tube-1.html

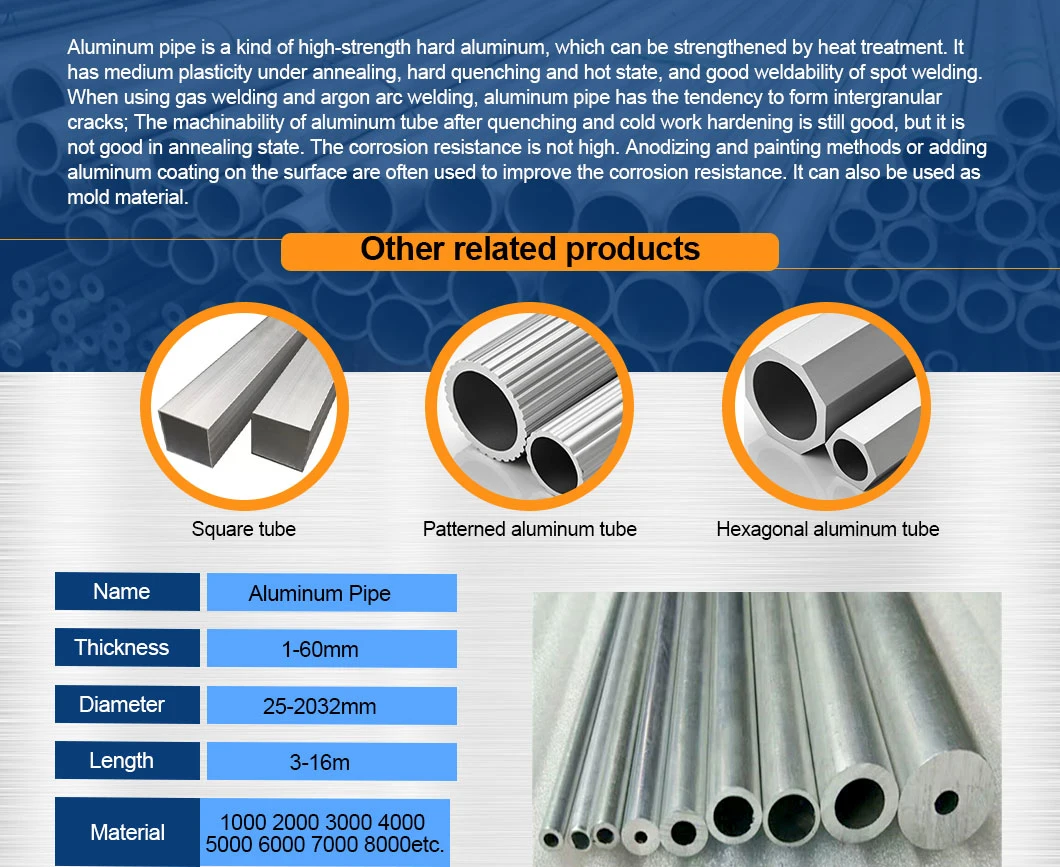

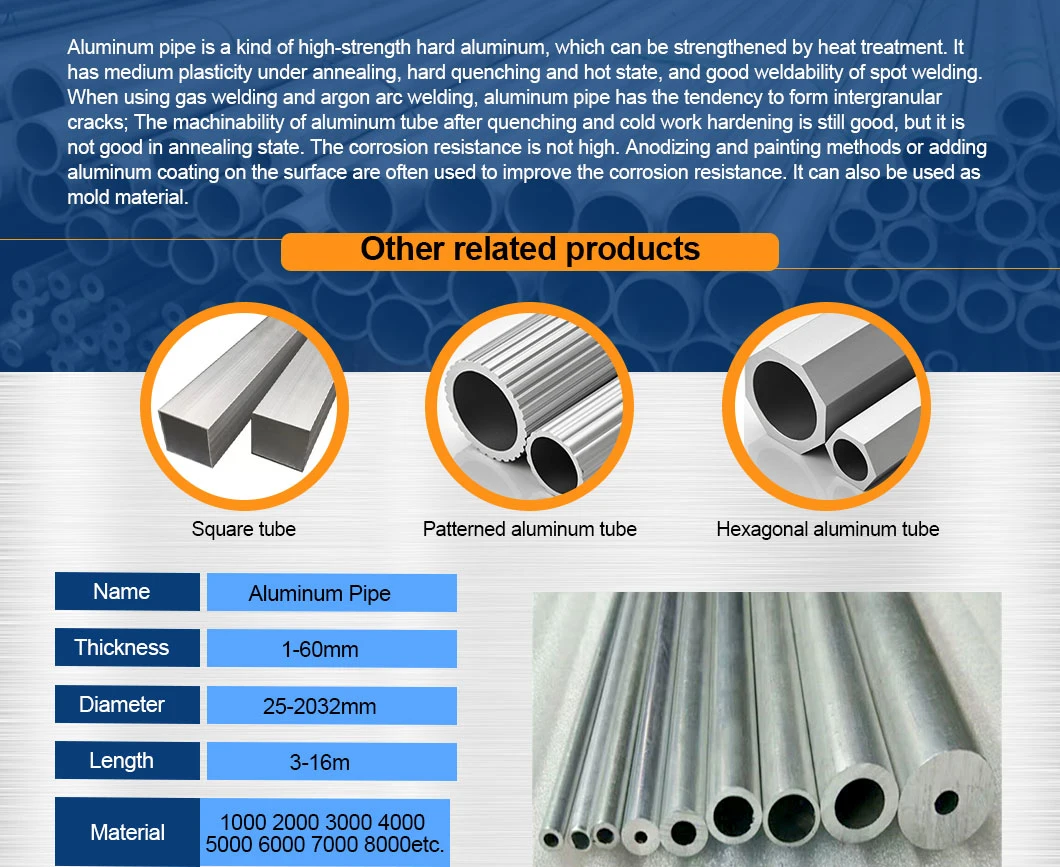

Aluminum tube is a kind of non-ferrous metal tube, which refers to a metal tubular material that is hollow along its longitudinal length through extrusion processing of pure aluminum or aluminum alloy.

There can be one or more closed through holes, the wall thickness and cross-section are uniform, and they are delivered in straight lines or in rolls.

They can be classified according to shape, extrusion method, precision, thickness, and performance.

Can be widely used in industries such as automobiles, ships, aerospace, aviation, electrical appliances, agriculture, electromechanical, and home furnishing.

Advantages of Seamless Aluminium Tube/Pipe:

Advantages of Seamless Aluminium Tube/Pipe:

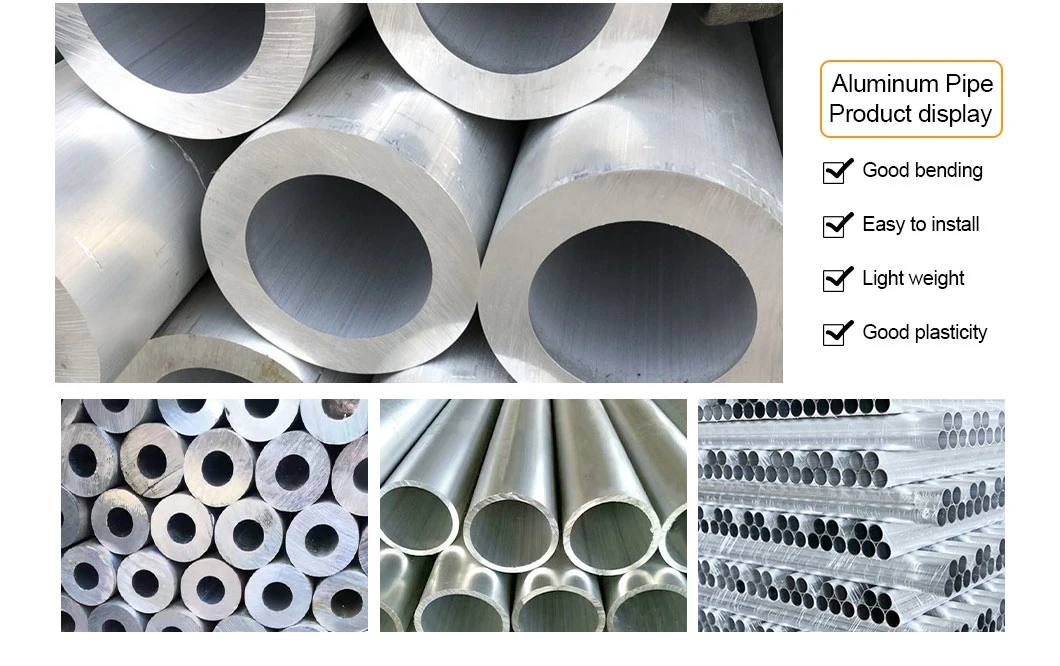

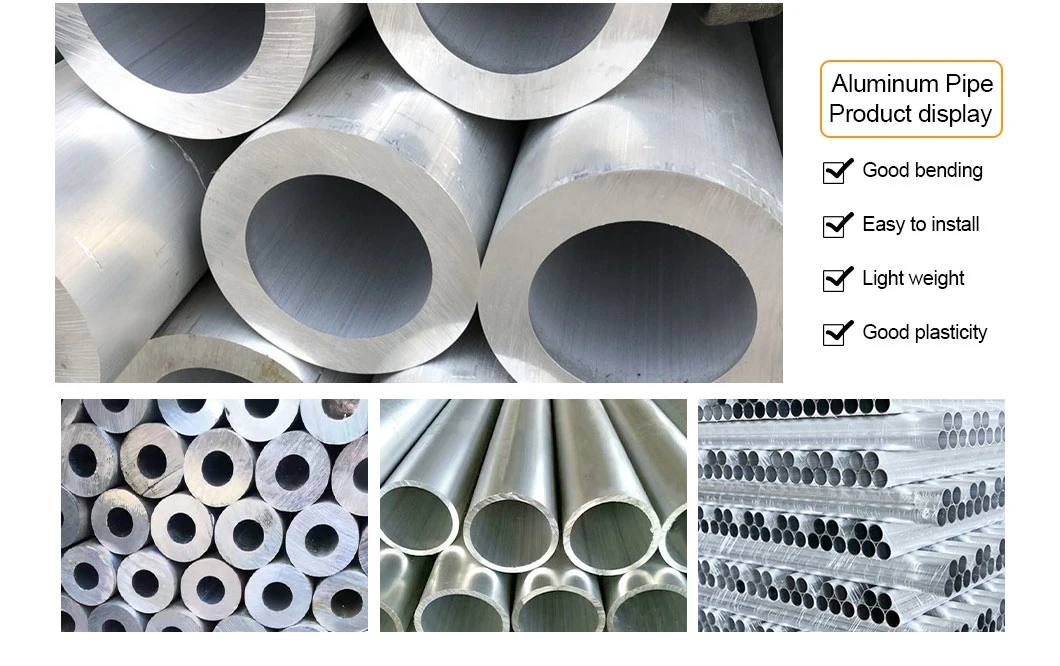

1.Without any weld seams, preferred for pressure vessels

2.More uniform anodizing appearance, especially on heavier wall sections

3.No weld seams that could split informing operation

4.Increased structural integrity

5.Good mechanical properties

6.Good corrosion resistance and oxidation resistance

Aluminum tube is a kind of non-ferrous metal tube, which refers to a metal tubular material that is hollow along its longitudinal length through extrusion processing of pure aluminum or aluminum alloy.

There can be one or more closed through holes, the wall thickness and cross-section are uniform, and they are delivered in straight lines or in rolls.

They can be classified according to shape, extrusion method, precision, thickness, and performance.

Can be widely used in industries such as automobiles, ships, aerospace, aviation, electrical appliances, agriculture, electromechanical, and home furnishing.

Advantages of Seamless Aluminium Tube/Pipe:

Advantages of Seamless Aluminium Tube/Pipe: 1.Without any weld seams, preferred for pressure vessels

2.More uniform anodizing appearance, especially on heavier wall sections

3.No weld seams that could split informing operation

4.Increased structural integrity

5.Good mechanical properties

6.Good corrosion resistance and oxidation resistance

| Chemical Composition(GB/T 3190-2008) | |||||||||||

| Alloy | Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Each | Total | Al. |

| 2024 | 0.5 | 0. 50 | 3.8~4.9 | 0.30~0.90 | 1.2~1.8 | 0. 10 | 0. 25 | 0. 15 | 0.05 | 0.15 | Remainder |

| 5052 | 0.25 | 0.4 | 0.1 | 0.1 | 2.2~2.8 | 0.15~0.35 | 0.1 | - | 0.05 | 0.15 | Remainder |

| 6061 | 0.4~0.8 | 0.7 | 0.15~0.4 | 0.15 | 0.8~1.2 | 0.04~0.35 | 0.25 | 0.15 | 0.05 | 0.15 | Remainder |

| 6063 | 0.20~0.6 | 0.35 | 0.1 | 0.1 | 0.45~0.9 | 0.1 | 0.1 | 0.1 | 0.05 | 0.15 | Remainder |

| 7075 | 0.4 | 0.5 | 1.2~2.0 | 0.3 | 2.1~2.9 | 0.18~0.28 | 5.1~6.1 | 0.2 | 0.05 | 0.15 | Remainder |