- Overview

- Product Parameters

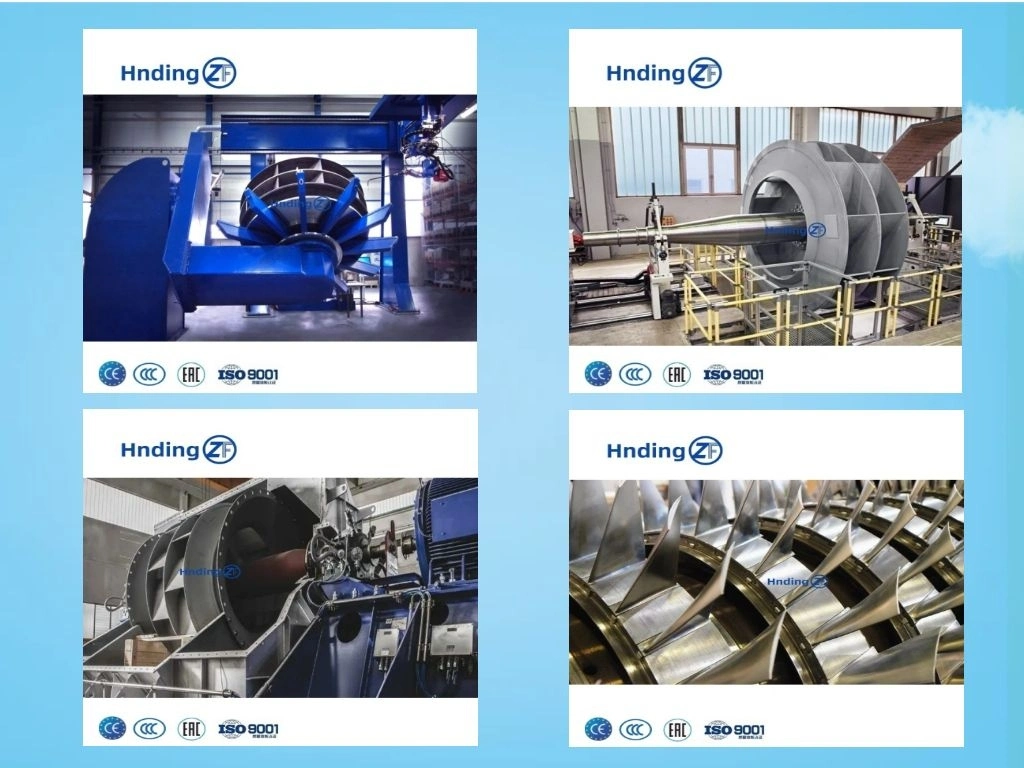

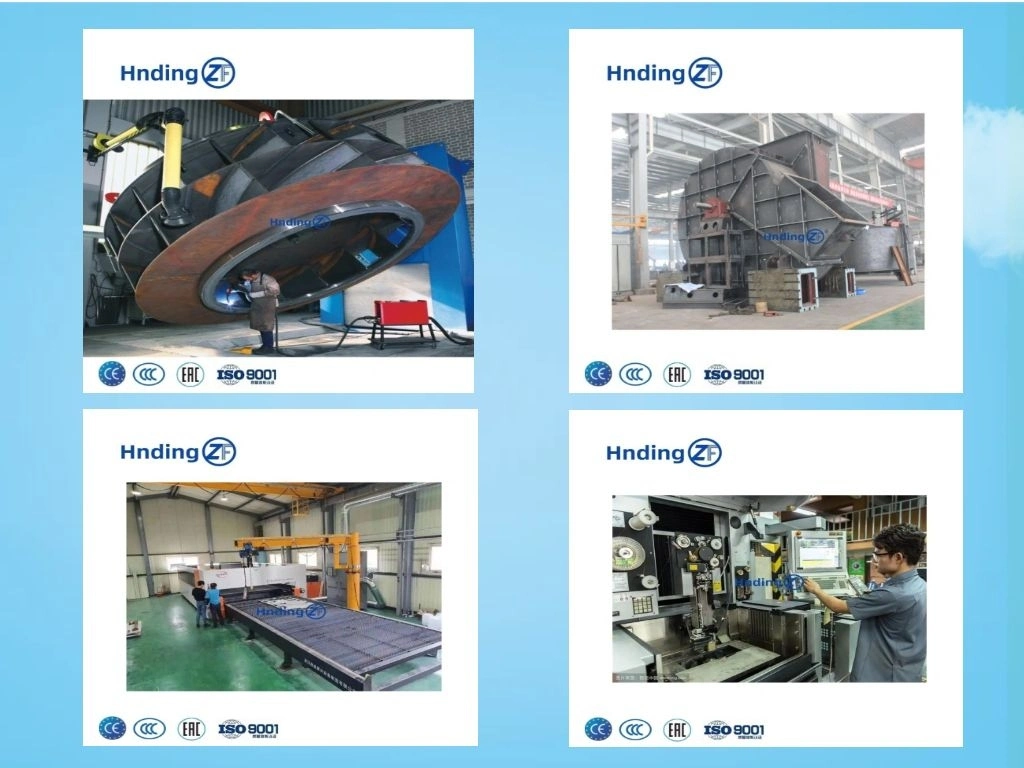

- Detailed Photos

- Certifications

- Packaging & Shipping

- Company Profile

- Our Advantages

- After Sales Service

- FAQ

Basic Info.

Packaging & Delivery

Product Description

SDS Series of Tunnel Axial Jet Fan

Overview

The specification of SDS is from 630mm to 1600mm, divided into two categories, namely, one-way operating shaft jet fan and reversible (two-way) operating shaft jet fan, with a maximum thrust of 3500N. High-efficiency and low-noise fans can be selected for any load and working condition.

SDS series jet fans adopt advanced technology to obtain good quality assurance. The fan shell is formed by spinning flanging of a special machine tool imported from the USA. The inner wall of the impeller section can not only guarantee the coaxial strength of the chassis but also guarantee the radial clearance of the blade. After hot dip galvanizing or other equivalent coating treatment, the appearance is beautiful and anticorrosive, with good performance. The fan blade and wheel hub are processed into die cavities by the automatic numerical control boring milling machining center of Toshiba Corporation of Japan. High (low) aluminum alloy die casting is done respectively in high-pressure casting and low-pressure casting machines. It has been proved by the practical use of highway tunnels, railway tunnels, and irrigation dam projects that the performance indexes, technical requirements, quality requirements, and economic indexes such as anticorrosion, reliability, and economy can be fully adapted to the use of various tunnels and subways.

In the construction of infrastructure projects such as subways, highway tunnels, and railway tunnels, the air quality standards and safety factors are met by forced ventilation of fans. As far as the ventilation system is concerned, it is necessary to maintain good air quality for a long time, otherwise, it is harmful to human health, as shown in the figure.

In principle, traffic tunnels can be divided into three types: a subway, a highway tunnel, and a railway tunnel.

The prerequisite for the safety and reliability of normal operation and emergency operation is the installation of the environmental control system which ensures the coordination between the systems and gives full play to its role.

A mechanical system: ventilation, fire control, sewage discharge

B power system: power supply, transmission, and distribution, emergency power

C lighting system: lighting, local lighting, fluorescent indicator

D communication system: telephone, radio, computer terminal

E traffic system: lighting, signal, sign, surveillance

F control system: monitoring of traffic condition, equipment condition, and equipment operation condition

The tunnel ventilation system may have three basic modes or adopt a hybrid mode.

1 longitudinal ventilation system: this is the most basic ventilation mode. Fresh air flows from the tunnel inlet to the outlet end. No ventilation pipe is required along the tunnel longitudinal. The ventilation mode is usually a reversible jet fan. The fan is installed on the top or side of the tunnel. It can be fully ventilated in two directions to achieve two-way ventilation or smoke control. If the tunnel is long, a central supply and exhaust shaft must be attached. The shaft is connected to the atmosphere and forms a hybrid ventilation mode.

Transverse ventilation systems: air delivery duct and air exhausting duct are set along the direction of the tunnel. The fresh air is collected from the wind pavilion and the exhaust is released from the wind tower. Generally, the air delivery duct is set below the road surface, and the air exhausting duct is set above the lane. The air delivery and exhausting ducts are provided with an air supply outlet and exhaust outlet at a certain interval, and the air is discharged timely along the tunnel cross-section under the accident condition, thus smoke is drawn out.

Semi-transverse ventilation system: this system can be divided into air supply type semi-transverse ventilation mode and air exhaust type semi-transverse ventilation mode, which generally adopts air exhaust type semi-transverse ventilation mode. Fresh air enters through the mouth of the entrance, and the air exhaust is similar to the full transverse ventilation system.

A project investment B power capacity C operating expenses D air quality E-safety factor F emergency guarantee measures

The above factors are integrated to establish the optimization program

5. Factors for choosing the number and type of ventilator in the tunnel ventilation system:

A CO, NOx, and smoke concentration

B vehicle flow (vehicle density, speed)

C wind load (length * width * height of tunnel)

D exhaust emission (vehicle age and quantity)

E emergency measures in case of fire

Resistance loss at the inlet and outlet, the friction coefficient of tunnel surface, and equipment

Vehicle friction coefficient (calculating vehicle motion or piston wind effects under the most unfavorable conditions)

The influence of external wind speed on outlet and inlet under the most unfavorable conditions, tunnel topography, position (slope, altitude)

Thrust required in case of fire (temperature, pressure, time)

N=C* mass flow * air velocity (N)

Where: N= fan static thrust (LSO) N value C= empirical correction coefficient

Mass flow = air density * volume flow

The jet fans used in the tunnel are related to the relative velocity of airflow in the tunnel, the friction coefficient in the tunnel, and the influence of parallel layout in the same group. Therefore, the effective thrust of the jet fans is:

N = N * (1 - V/V) C * C

Where: N= fan effective thrust (N) V= wind speed in the tunnel (m/s)

V= jet velocity (m/s) C= friction coefficient in the tunnel

C= the flow loss caused by the parallel layout in the same group (the loss, such as the distance between the fan units, is 100 times the diameter of the fan, so that the jet velocity does not affect the operating conditions along the airflow direction, and it can not be considered).

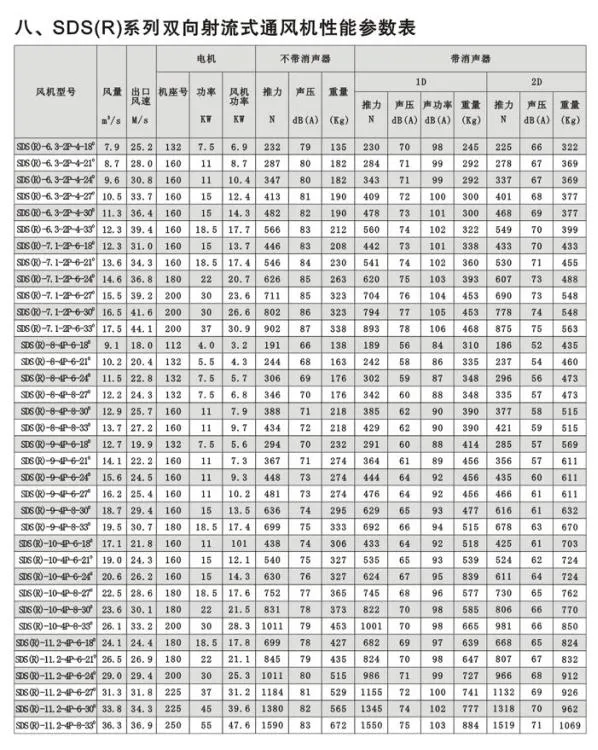

The tunnel jet fan has two ventilation modes: a one-way jet fan (SDS) and a tunnel jet fan (SDS(R).

Fan body, muffler, supporter's foot: adopt steel plate numerical control automatic welding and machine molding, surface coating is applied to the appearance to guarantee the fan strength and anti-corrosion

Fan impeller: to meet the needs of tunnel ventilation, SDS series fans can change the number of blades and the angle of the blades.

Muffler: the length of the muffler is usually one time the diameter of the fan. When the noise demand is high, the diameter of the fan can be doubled. The muffler and the fan body are fixed by bolts.

Auxiliary motor: the auxiliary motor of the SDS series jet fan is totally enclosed with a squirrel cage. The motor is equipped with a flange mounting plate. The insulation grade of the motor is H and the anticorrosion grade is IP55. The motor outgoing cable can be connected to the terminal box on the chassis of the fan body. The motor is equipped with a lubricating grease nozzle and the external metal hose is connected to the lubricating grease nozzle on the chassis of the fan body.

Fan reversible switching time: under a state of emergency, jet fan positive and negative switching time is very important. SDS (R) fan has two switching methods, electronic and mechanical, which can switch to the rated speed of the fan in 30 seconds.

SDS series jet fan experiment test

Thrust test: measured by the thrust test device.

High-temperature fire test: tested by Tianjin fire experiment and testing center of the Ministry of public security.

Noise test: the muffler installed at the inlet and outlet of the fan and the non-muffler are tested on the open field (when the atmospheric wind speed is close to 0). The sound pressure level test is measured at a 45 ° angle along the axis of the fan and 10 m away from the fan.

Fan efficiency: fan operation efficiency is defined by measuring thrust (N) and motor input power (KW).

The experiment test is carried out by the engineering technology center (experiment and research center) of the company in strict accordance with the relevant national and industrial standards and has been tested by provincial and national authoritative supervision institutions.

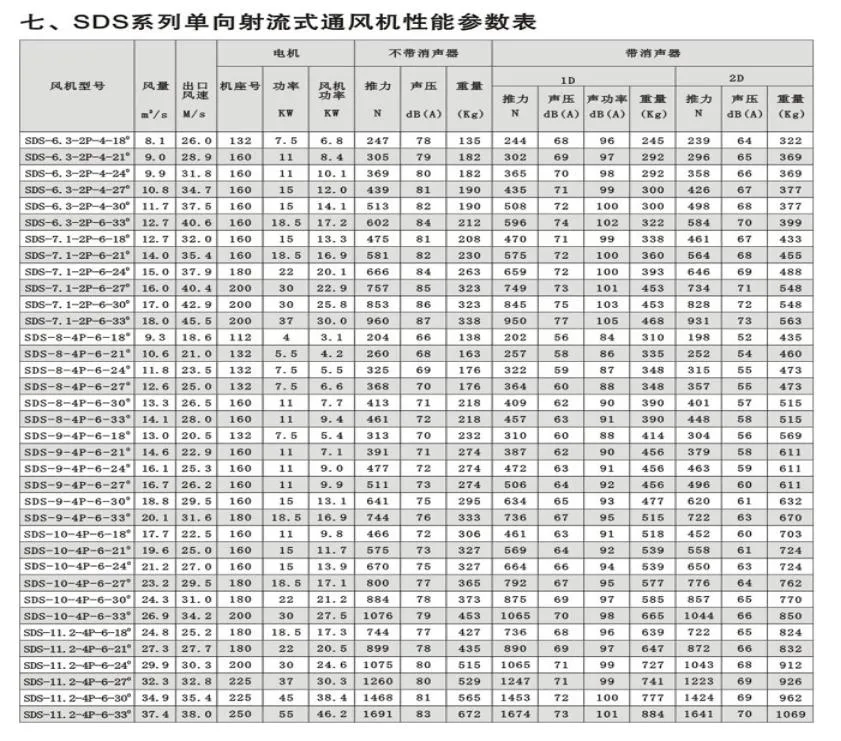

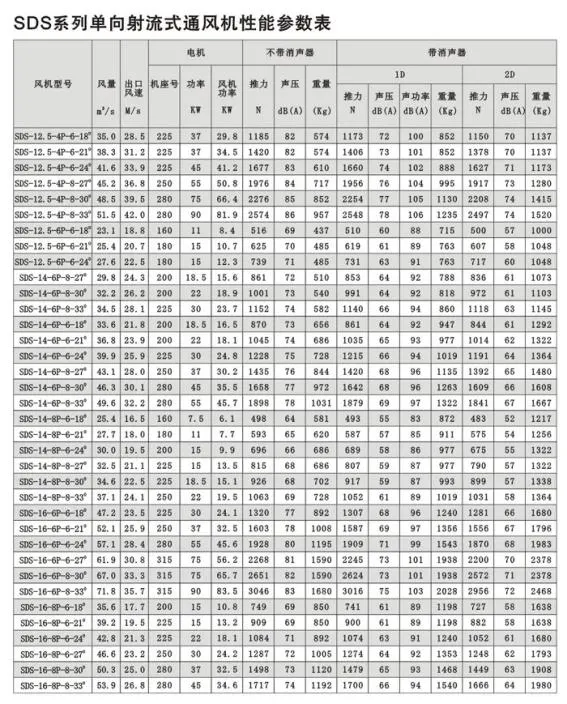

SDS series one-way jet fan performance parameter table

| Type of fa n | Air volume | Outlet air velocity | Motor | Non -muffler | Muffler | |||||||||||

| Frame number | power | Fan power | thrust | Sound pressure | weight | thrust | Sound pressure | Sound power | weight | thrust | Sound pressure | weight | ||||

1) The equipment is equipped with a number of signs such as a product nameplate, rotation direction sign, wind direction sign, grounding sign, lifting sign, safety warnings, and so on.

2) Product nameplate mainly includes the contents of the equipment: main technical parameters (flow, pressure, motor power, Revolutions Per Minute), product number, manufacturing date, and so on, which is convenient for users to check at any time

3) Small equipment adopts the type of export wood packaging and large equipment, and the steel frame transports large cargo transportation.

4) All equipment is waterproof and rainproof.

Strict quality standards, precision machining, and other spare parts and design maintain product stability, strictly select product parts suppliers, and perfect after-sales service system to allow customers to enjoy a new experience

Our company has introduced the latest research results of the Chinese Academy of Sciences, C4-II ternary flow wing twisted blades, which have high aerodynamic efficiency.

The surface of the ventilator impeller blade is sprayed with advanced super-resistant (CN) metal material to form a wear-resistant, anti-corrosion protection layer on the surface of the blade. The wear resistance of the blade surface is 10 to 50 times higher than that of the ordinary carbon steel material, thereby greatly prolonging the service life of the blade.

Quality assurance measures:

In long-term production management, our company has formed a set of standardized process control measures and control points, which can provide users with high-quality products in all directions. Our company has a good reputation and is an enterprise that users can trust.

Our company has obtained the IS09001 certification from the International Organization for Standardization (see Enterprise Qualification Materials for details). We strictly standardize the operation process and control points of product manufacturing

When the equipment of the buyer is installed, our company is responsible for on-site installation guidance, personnel training and commissioning of t est - drive , The separately purchased fan accessories can be used for telephone connection guidance and debugging

Our company guarantees that the structural safety, aerodynamic performance, running noise, and appearance, quality of the supplied ventilators can be checked and accepted by relevant departments.

The quality assurance period for the supplied ventilator equipment, except for special provisions, is 18 months from the final acceptance of the ventilator.

Q. What information should I provide when inquiring?

A: Fan name/model, KW, Air pressure, Flow rate Air Volume, and temperature

Q. What is your warranty?

A. Our warranty is 18 months after receiving the fans. During the warranty period, replace the damaged parts free of charge. Out warranty period, to provide timely, high-quality technical services and price concessions spare parts to ensure.

continuous safe and high-quality equipment operation.

Q. How does your factory control product quality?

A. We have a quality inspection department. All fans are running more than 3 hours before delivery to test the quality. If there is a quality problem, we will produce a new one.

Q. What are your terms of payment?

A. TT 40% AS THE ADVANCE PAYMENT AND TT 60% AFTER INSPECTION BEFORE SHIPPING.

B. 100% IRREVOCABLE L/C AT STGHT.

Q. What products do you produce?

A. Centrifugal fan, tunnel fan, axial fan, jet fan, mining fan, exhaust fan,anti-corrosion blower, high-pressure blower, explosion proof fan, fan accessories, etc, welcome to contact us to learn more details.

Q. Where is your factory? Can I visit your factory?

A. Zibo Hengding Fan Co., Ltd. Is located in Industrial Park, Beijiao Town, Zhoucun District, Zibo City, Shandong Province, China.

Q. How long will it take to ship after the order?

A. 10-15 Days if you need it urgently, we can discuss it for shorting time.

Q. Is the product customizable?

A. Various types can be customizable.

https://hengdingfan.en.made-in-china.com/contact-info.html