- Overview

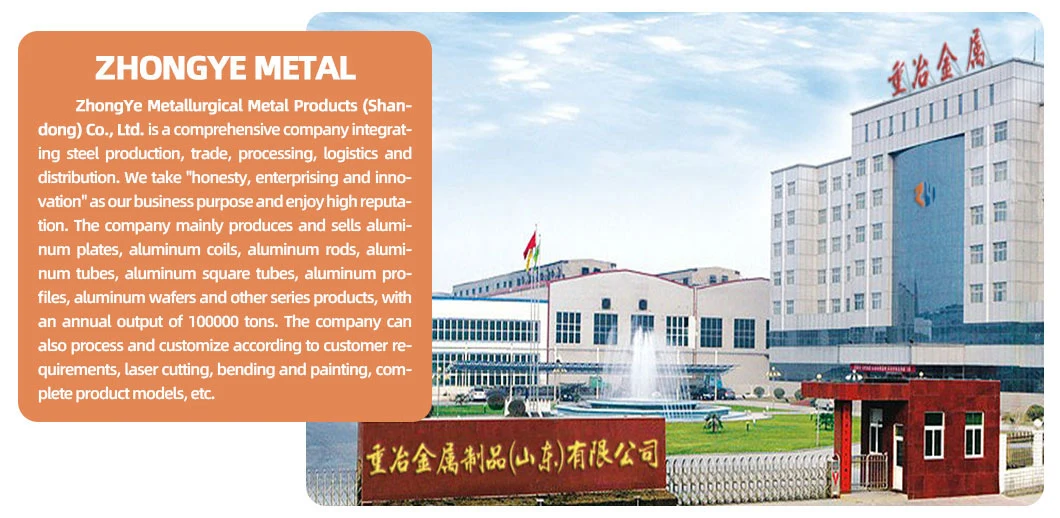

- Company Profile

- Product Parameters

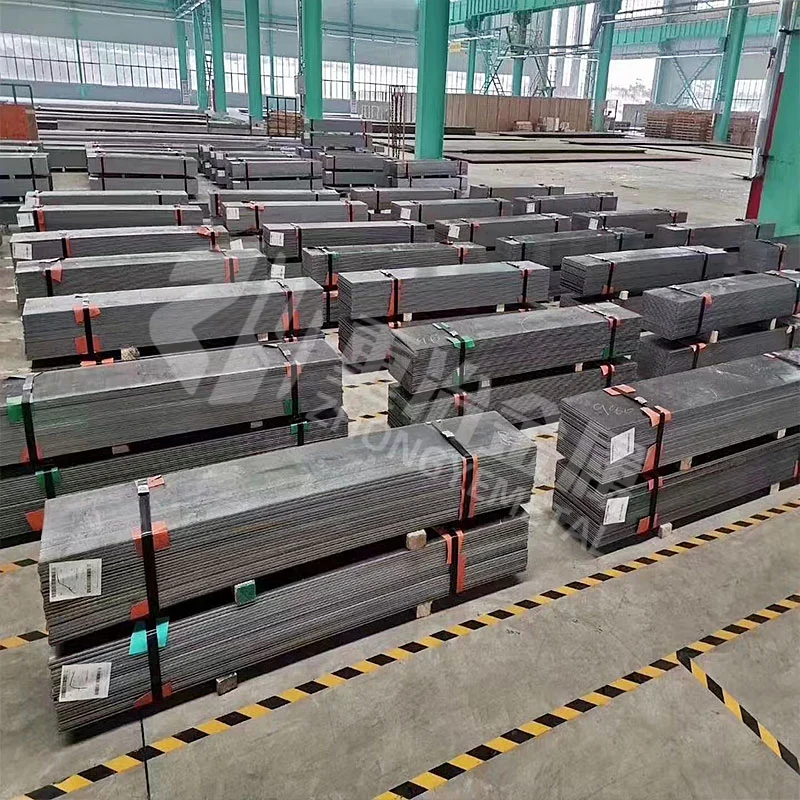

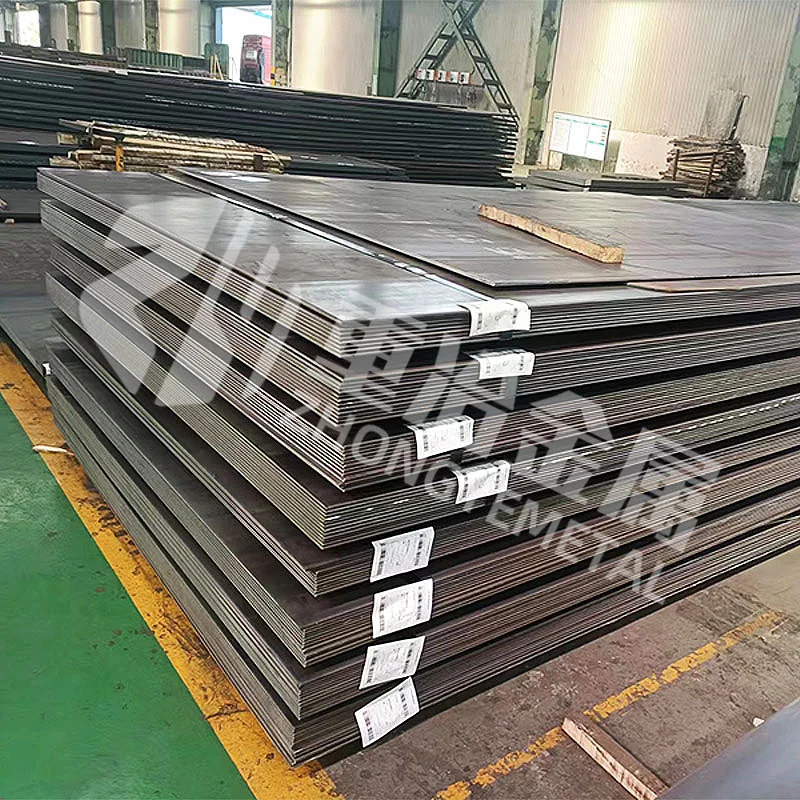

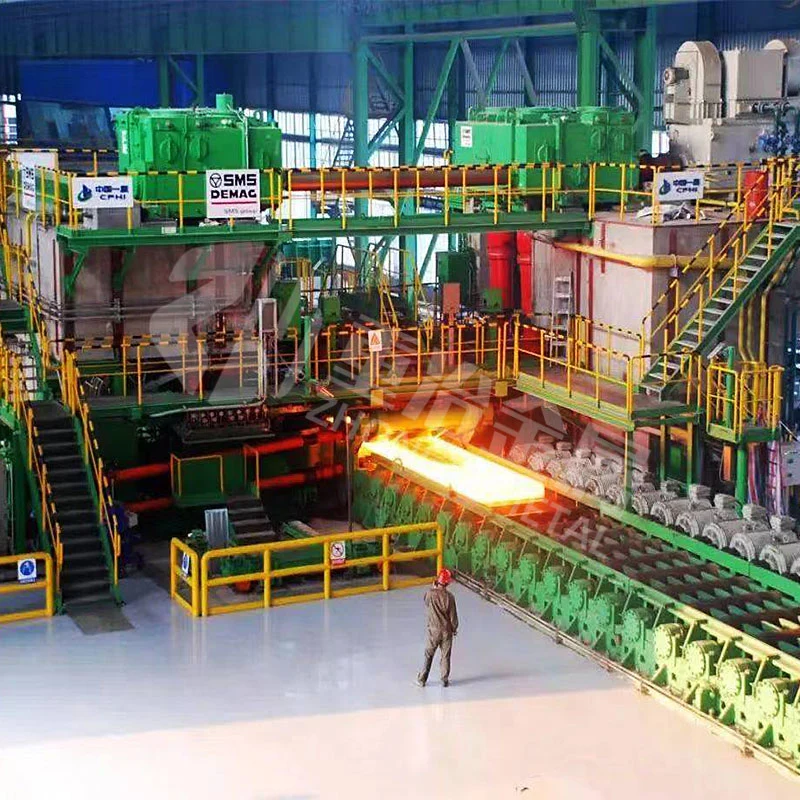

- Detailed Photos

- Packaging & Shipping

- Our Advantages

- Certifications

- FAQ

Basic Info.

Product Description

Alloy steel sheet

Alloy steel sheet The steel plate is flat, rectangular and can be rolled directly or cut from a wide strip of steel.

According to the thickness of the steel plate, thin steel <4 mm (the thinest 0.2 mm), thick steel plate 4~60 mm, extra thick steel plate 60~115 mm.

Steel plate is divided into hot rolled and cold rolled according to rolling. The width of the sheet is 500~1500 mm; The width of the thickness is 600~3000 mm. The sheet is divided into ordinary steel, high quality steel, alloy steel, spring steel, stainless steel, tool steel, heat-resistant steel, bearing steel, silicon steel and industrial pure iron sheet, etc. According to

professional use, there are oil drum plate, enamel plate, bulletproof plate, etc.; According to the surface coating, there are

galvanized sheet, tin sheet, lead sheet, plastic composite steel plate, etc.

| Alloy steel plate | |||

| Classification of alloy steel plates | According to the content of alloying elements Low alloy steel (the total amount of alloying elements is less than 5%), Medium alloy steel (the total amount of alloying elements is 5%-10%) High alloy steel (the total amount of alloying elements is higher than 10%). According to the composition of alloy elements Chromium steel (Cr-Fe-C) Chromium-nickel steel (Cr-Ni-Fe-C) Manganese steel (Mn-Fe-C) Silicon manganese steel (Si-Mn-Fe-C) According to metallographic organization Pearlite steel Martensite steel ferritic steel austenitic steel ledeburitic steel Divide by purpose structural alloy steel 4cr5mosiv1 Special performance steel | ||

| Properties of alloy steel plate | (1) Low hardenability Generally, the maximum hardenability diameter of carbon steel by water quenching is only 10 mm-20 mm.. (2) The strength and yield strength are relatively low. For example, the σs of ordinary carbon steel Q235 steel is 235MPa, while the σs of low alloy structural steel 16Mn is above 360MPa. σs /σb of 40 steel is only 0.43, which is much lower than that of alloy steel. (3) Poor tempering stability Due to poor tempering stability, when tempering carbon steel, it is necessary to adopt a lower tempering temperature in order to ensure higher strength, so that the toughness of steel is low; In order to ensure good toughness, the strength is low at high tempering temperature, so the comprehensive mechanical properties of carbon steel are not high. (4) carbon steel that can't meet the requirements of special properties is often poor in oxidation resistance, corrosion resistance, heat resistance, low temperature resistance, wear resistance and special electromagnetic properties, and can't meet the requirements of special performance. | ||

| Main steel grade | executive standard | Specification range and delivery status | main application |

| 15CrMo,20CrMo,30CrMo | GB3077 | 1. Specification scope: Can be customized according to requirements. The maximum unit weight of steel plate is 500 tons; 2. Delivery status: According to the performance and user's needs, steel plates can be delivered in hot rolling, controlled rolling, normalizing, annealing, tempering, normalizing+tempering, quenching and tempering, etc. 3, flaw detection and thickness direction performance: It can produce Z15-Z35 steel plates with additional flaw detection requirements and tear resistance (thickness direction performance), and can also provide Z direction performance steel plates according to ASTM, A770 and other standards. | It is used to make all kinds of alloy structural parts and their parts, such as superheater header of power plant boiler and large-diameter tubesheet structural parts. |

| 35CrMo,20Cr,40Cr | GB11251 | ||

| 20Mn2,40Mn2 | GB /T 3077 | ||

| 20CrMnMo,12Cr1MoV | GB /T 3077 | ||

| 10CrMoAL | GB /T 30070-2013 | ||

| 25CrMo4,34CrMo4,42CrMo4 | EN10083-1 | ||

| 30CrMnSiA,35CrMnSiA | WYJ21-98 | ||

| 42CrMo | SYJ17-99 | ||

| 21CrMo10 | WYJ16-99 | ||

| GB Alloy Steel Plate Chemical Composition | ||||||

| Grade | C | Si | Mn | Cr | Mo | Other |

| 20Mn2 | 0.17-0.24 | 0.17-0.37 | 1.40-1.80 | | | |

| 30Mn2 | 0.27-0.34 | 0.17-0.37 | 1.40-1.80 | | | |

| 35Mn2 | 0.32-0.39 | 0.17-0.37 | 1.40-1.80 | | | |

| 45Mn2 | 0.42-0.49 | 0.17-0.37 | 1.40-1.80 | | | |

| 27SiMn | 0.24-0.32 | 1.10-1.40 | 1.10-1.40 | | | |

| 35SiMn | 0.32-0.40 | 1.10-1.40 | 1.10-1.40 | | | |

| 40B | 0.37-0.44 | 0.17-0.37 | 0.60-0.90 | | | B 0.0008-0.0035 |

| 45B | 0.42-0.49 | 0.17-0.37 | 0.60-0.90 | | | B 0.0008-0.0035 |

| 50B | 0.47-0.55 | 0.17-0.37 | 0.60-0.90 | | | B 0.0008-0.0035 |

| 15Cr | 0.12-0.17 | 0.17-0.37 | 0.40-0.70 | 0.70-1.00 | | |

| 20Cr | 0.18-0.24 | 0.17-0.37 | 0.50-0.80 | 0.70-1.00 | | |

| 30Cr | 0.27-0.34 | 0.17-0.37 | 0.50-0.80 | 0.80-1.10 | | |

| 35Cr | 0.32-0.39 | 0.17-0.37 | 0.50-0.80 | 0.80-1.10 | | |

| 40Cr | 0.37-0.44 | 0.17-0.37 | 0.50-0.80 | 0.80-1.10 | | |

| 45Cr | 0.42-0.49 | 0.17-0.37 | 0.50-0.80 | 0.80-1.10 | | |

| 50Cr | 0.47-0.54 | 0.17-0.37 | 0.50-0.80 | 0.80-1.10 | | |

| 38CrSi | 0.35-0.43 | 1.00-1.30 | 0.30-0.60 | 1.30-1.60 | | |

| 12CrMo | 0.08-0.15 | 0.17-0.37 | 0.40-0.70 | 0.40-0.70 | 0.40-0.55 | |

| 15CrMo | 0.12-0.18 | 0.17-0.37 | 0.40-0.70 | 0.80-1.10 | 0.40-0.55 | |

| 20CrMo | 0.17-0.24 | 0.17-0.37 | 0.40-0.70 | 0.80-1.10 | 0.15-0.25 | |

| 25CrMo | 0.22-0.29 | 0.17-0.37 | 0.60-0.90 | 0.90-1.20 | 0.15-0.30 | |

| 30CrMo | 0.26-0.33 | 0.17-0.37 | 0.40-0.70 | 0.80-1.10 | 0.15-0.25 | |

| 35CrMo | 0.32-0.40 | 0.17-0.37 | 0.40-0.70 | 0.80-1.10 | 0.15-0.25 | |

| 42CrMo | 0.38-0.45 | 0.17-0.37 | 0.50-0.80 | 0.90-1.20 | 0.15-0.25 | |

| 50CrMo | 0.46-0.54 | 0.17-0.37 | 0.50-0.80 | 0.90-1.20 | 0.15-0.30 | |

| 12CrMoV | 0.08-0.15 | 0.17-0.37 | 0.40-0.70 | 0.30-0.60 | 0.25-0.35 | V 0.15-0.30 |

| 12Cr1MoV | 0.08-0.15 | 0.17-0.37 | 0.40-0.70 | 0.90-1.20 | 0.25-0.35 | V 0.15-0.30 |

| 38CrMoAl | 0.35-0.42 | 0.20-0.45 | 0.30-0.60 | 1.35-1.65 | 0.15-0.25 | Al 0.70-1.10 |

| 40CrV | 0.37-0.44 | 0.17-0.37 | 0.50-0.80 | 0.80-1.10 | | V 0.10-0.20 |

| 15CrMn | 0.12-0.18 | 0.17-0.37 | 1.10-1.40 | 0.40-0.70 | | |

| 20CrMnSi | 0.17-0.23 | 0.90-1.20 | 0.80-1.10 | 0.80-1.10 | | |

| 25CrMnSi | 0.22-0.28 | 0.90-1.20 | 0.80-1.10 | 0.80-1.10 | | |

| 30CrMnSi | 0.28-0.34 | 0.90-1.20 | 0.80-1.10 | 0.80-1.10 | | |

| 35CrMnSi | 0.32-0.39 | 1.10-1.40 | 0.80-1.10 | 1.10-1.40 | | |

| 20CrMnMo | 0.17-0.23 | 0.17-0.37 | 0.90-1.20 | 1.10-1.40 | 0.20-0.30 | |

| 20CrMnTi | 0.17-0.23 | 0.17-0.37 | 0.80-1.10 | 1.00-1.30 | | Ti 0.04-0.10 |

| 20CrNiMo | 0.17-0.23 | 0.17-0.37 | 0.60-0.95 | 0.40-0.70 | 0.20-0.30 | Ni 0.35-0.75 |

| 40CrNiMo | 0.37-0.44 | 0.17-0.37 | 0.50-0.80 | 0.60-0.90 | 0.15-0.25 | Ni 1.25-1.65 |

1. Who are we?

Our headquarters is located in Shandong, China. Since 2002, we have been selling to the domestic market (40.00%), Northern Europe (8.00%), North America (7.00%), the Middle East (7.00%), Africa (6.00%), South America (5.00%), Southeast Asia (5.00%), East Asia (5.00%), South Asia (5.00%), Eastern Europe (3.00%), Western Europe (3.00%), Central America (3.00%), Southern Europe (2.00%), and Oceania (1.00%). There are about 101-200 people in our office.

2. How do we guarantee quality?

Pre-production samples are always available before mass production;

Always carry out final inspection before shipment;

3. What can you buy from us?

Aluminum plate, aluminum coil, aluminum foil, carbon steel, alloy steel, stainless steel, copper galvanizing, etc

4. Why should you buy from us instead of other suppliers?

ZhongYe Metal Products (Shandong) Co., Ltd. is a leading manufacturer of aluminum products and carbon alloy materials in China, with more than 20 years of experience. More than 160 experienced workers use German brand processing equipment for production.

5. What services can we provide?

Accepted delivery conditions: FOB, CIF, FAS, DDP, express, DES;

Accepted payment currencies: US dollar, Australian dollar, Euro and RMB;

Payment types accepted: T/T, L/C, MoneyGram, credit card, PayPal, Western Union remittance, cash;

6. After-sales service: 24-hour online maintenance guidance service.

Language: English, Chinese Other.