Basic Info.

Surface Treatment

Ba, 2b, No.1, No.4, 8K, Hl, Mirror Finish

Surface Finish

2b/Ba/400g/600g/800g/180hl/PVD Color/Mirror/Satin

Delivery Time

7-14 Days

Length

1-12m, as Requiremen

Thickness

0.1-60mm

Outer Diameter

100mm, 6mm-2500mm (3/8"-100")

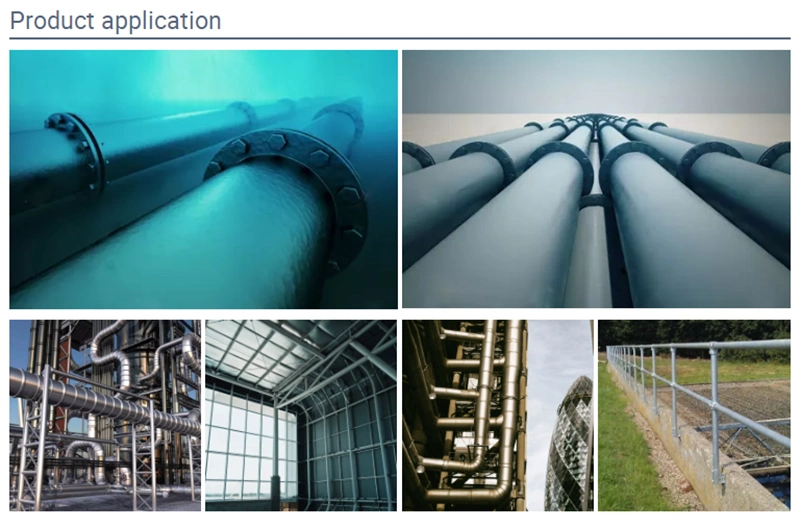

Application

Heat Exchange, Boile, Power, Chemical Factory etc

Technology

Cold Drawing Annealed

Tolerance

5%

Material

304, 304L, 316, 316L, 317L, 321, 347, etc

Alloy or Not

Is Alloy

Welding Line Type

Seamless/Welding

Ends

Plain Ends Bevel Ends

Transport Package

Plastic Bag+PVC Film+Wooden Case

Specification

As requirement

Trademark

Hanhuang

Origin

Jiangsu

Production Capacity

5000t/Month

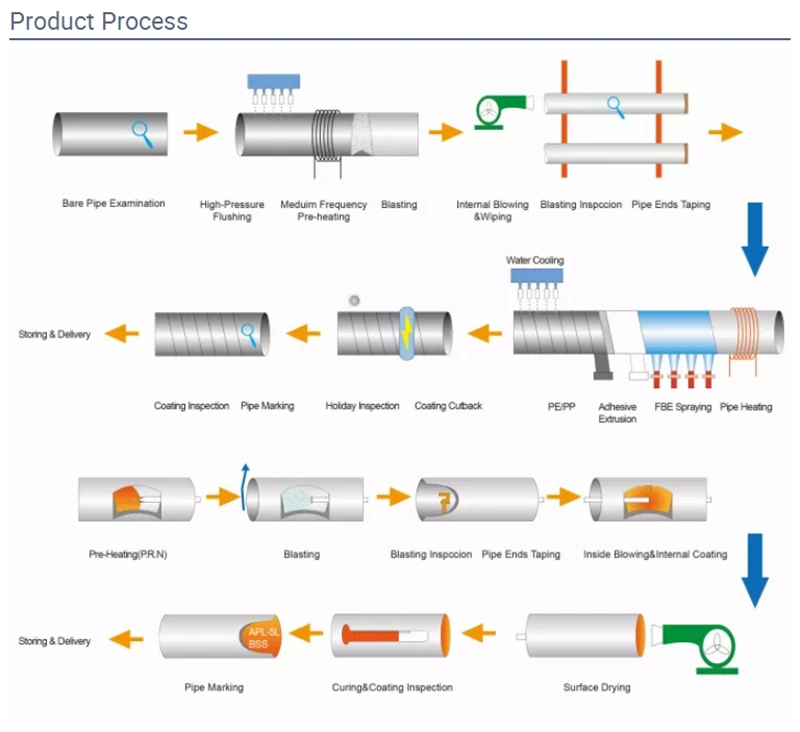

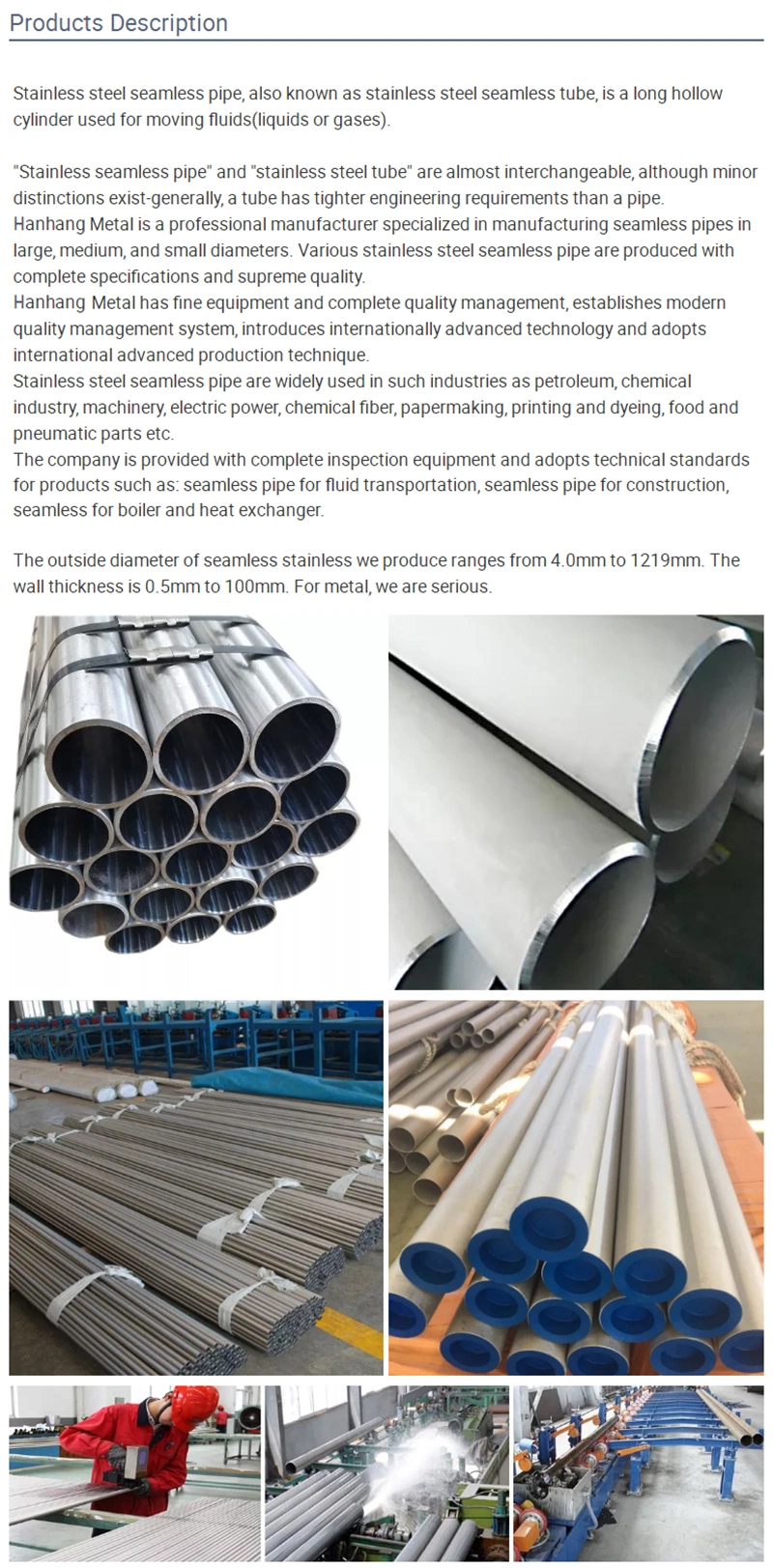

Product Description

Hanhuang Steel is group company in the steel manufacture & Trading, founded in the 2000s, 800+ staff, 25, 000+ m2 non-dust workshop, 40+ great large mills and cooperation partners in China, 4000, 000+ MT production per year under ISO management, 40, 000+customers in domestic and overseas market, 10 billion USD of annual turnover, 15+ subsidiary companies all over China, ranking the Top 100 private enterprises in China, 1 hour reach Shanghai/Tianjin /Guangzhou Port, we keep high quality, competitive price, thousands tons of stock, most efficient delivery and reliable cooperation for global valued customers. We have been engaging industry steel for over 20 years, best service and the most competitive price is one of our greatest advantages that make us today!

Stainless steel pipe is one of the hot-selling products of HANHUANG Steel.

Stainless steel pipe's diameter we produce ranges from 0.25mm to 16mm.

It includes stainless steel capillary pipe, precision stainless steel pipe, and coiled stainless steel pipe.

The pipes are inventoried mainly in 304, 304L, 316, 316L, 310s, 321, 309, etc.

They are wide used in different fields, such as medical device industry, temperature-guided industrial temperature control, sensor used pipe, pens care industry core tube, car antenna tube, mobile phone and computer stylus, etc.

It includes stainless steel capillary pipe, precision stainless steel pipe, and coiled stainless steel pipe.

The pipes are inventoried mainly in 304, 304L, 316, 316L, 310s, 321, 309, etc.

They are wide used in different fields, such as medical device industry, temperature-guided industrial temperature control, sensor used pipe, pens care industry core tube, car antenna tube, mobile phone and computer stylus, etc.

As a leading stainless steel pipe manufacturer, hanhuang Steel adheres to strict quality standards to produce our stainless steel pipes. We guarantee our products meet our customer's requirement.

| Specification | |

| Size | Outer Diameter: 6-2500mm (3/8"-100"); Wall Thickness: 1-150mm (SCH10-XXS); Length: As your request |

| Process | Welded |

| Standard | ASTM, DIN, ISO, EN, JIS, GB, etc |

| Material | 200 series (201, 201L, 201LN, 202, etc) 300 series (304, 304L, 309S, 310S, 316, 316Ti, 317, 317L, 321, 347, 347H, 316L, etc) 400 series (401, 409, 410, 420J1, 420J2, 430, 439, 440, 440C, 443, 444, etc) Duplex steel (2205, 2507, etc) |

| Surface | Polishing, annealing, pickling, bright |

| Type | hot rolled and cold rolled |

| Price terms | FOB, CIF, CFR, CNF, Ex-work |

| Payment terms | T/T, L/C, westen union |

| Delivery time | Prompt delivery or as the order quantity |

| Package | Standard export seaworthy package,or as required. |

| Application | Widely used in petroleum, foodstuff, chemical industry, construction, electric power, nuclear, energy, machinery, biotechnology, paper making, shipbuilding, boiler fields. |

| Container size | 20ft GP: 5898mm(Length)x2352mm(Width)x2393mm(High) 24-26CBM 40ft GP: 12032mm(Length)x2352mm(Width)x2393mm(High) 54CBM 40ft HC: 12032mm(Length)x2352mm(Width)x2698mm(High) 68CBM |

| Stainless Steel Grades | ||||

| EN-DIN standard steel grade | EN-standard steel grade | ASTM /AlSIstandard steel grade | UNS | GB-standard steel grade |

| 1.431 | X10CrNi18-8 | 301 | | |

| 1.4318 | X2CrNiN18-7 | 301LN | | |

| 1.4307 | X2CrNi18-9 | 304L | S30403 | |

| 1.4306 | X2CrNi19-11 | 304L | S30403 | 00Cr18Ni9 |

| 1.4311 | X2CrNiN18-10 | 304LN | S30453 | |

| 1.4301 | X5CrNi18-10 | 304 | S30400 | 06Cr19Ni10 ( GB/T3280-2007 ) |

| 1.4948 | X6CrNi18-11 | 304H | S30409 | |

| 1.4303 | X5CrNi18 12 | 305 | | |

| 1.4541 | X6CrNiTi18-10 | 321 | S32100 | 0Cr18Ni11Ti |

| 1.4878 | X12CrNiTi18-9 | 321H | S32109 | |

| 1.4404 | X2CrNiMo17-12-2 | 316L | S31603 | 00Cr17Ni14Mo2 |

| 1.4432 | X2CrNiMo17-12-3 | 316L | S31603 | 00Cr17Ni14Mo2 |

| 1.4435 | X2CrNiMo18-14-3 | 316L | S31603 | 00Cr17Ni14Mo2 |

| 1.4401 | X5CrNiM017-12-2 | 316 | S31603 | 0Cr17Ni12Mo2 |

| 1.4436 | X3CrNiMo17-13-3 | 316 | S31603 | 0Cr17Ni12Mo2 |

| 1.4406 | X2CrNiM0N17-12-2 | 316LN | S31653 | |

| 1. 4571 | X6CrNiMoTi17-12-2 | 316Ti | S31653 | |

| 1.4429 | X2CrNiMoN17-13-3 | 316LN | S31653 | |

| 1.4438 | X2CrNiMo18-15-4 | 317L | S31703 | |

| | X10CrNiTi189 | 347 | | 0Cr18Ni1 1Nb |

| 1.4512 | X6CrTi12 | 409 | | 0Cr11Ti |

| | | | S41000 | 0Cr13 |

| | | 410 | | 1Cr13 |

| | | 420J1 | | 2Cr13 |

| 1.4016 | X6Cr17 | 430 | | 1Cr17 |

| 1.4118 | X40CrMo15 | 440A | S44002 | 8Cr13 |

| 1.4112 | | 440B | S44004 | 9Cr13 |

| 1.4125 | | 440C | S44003 | 11Cr18 |

| | | 440F | S44020 | |

| 1. 4539 | X1NiCrMoCu25-20-5 | 904L | N08904 | 00Cr20Ni25Mo4. 5Cu |

| 1. 4547 | X1CrNiMoCuN20-18-7 | | S31254 | |

| Chemical Composition % | ||||||||

| Grade | C | Si | Mn | P | S | Ni | Cr | Mo |

| 201 | ≤0 .15 | ≤0 .75 | 5. 5-7. 5 | ≤0.06 | ≤ 0.03 | 3.5 -5.5 | 16 .0 -18.0 | - |

| 202 | ≤0 .15 | ≤l.0 | 7.5-10.0 | ≤0.06 | ≤ 0.03 | 4.0-6.0 | 17.0-19.0 | - |

| 301 | ≤0 .15 | ≤l.0 | ≤2.0 | ≤0.045 | ≤ 0.03 | 6.0-8.0 | 16.0-18.0 | - |

| 302 | ≤0 .15 | ≤1.0 | ≤2.0 | ≤0.035 | ≤ 0.03 | 8.0-10.0 | 17.0-19.0 | - |

| 304 | ≤0 .0.08 | ≤1.0 | ≤2.0 | ≤0.045 | ≤ 0.03 | 8.0-10.5 | 18.0-20.0 | - |

| 304L | ≤0.03 | ≤1.0 | ≤2.0 | ≤0.035 | ≤ 0.03 | 9.0-13.0 | 18.0-20.0 | - |

| 309S | ≤0.08 | ≤1.0 | ≤2.0 | ≤0.045 | ≤ 0.03 | 12.0-15.0 | 22.0-24.0 | - |

| 310S | ≤0.08 | ≤1.5 | ≤2.0 | ≤0.035 | ≤ 0.03 | 19.0-22.0 | 24.0-26.0 | |

| 316 | ≤0.08 | ≤1.0 | ≤2.0 | ≤0.045 | ≤ 0.03 | 10.0-14.0 | 16.0-18.0 | 2.0-3.0 |

| 316L | ≤0 .03 | ≤1.0 | ≤2.0 | ≤0.045 | ≤ 0.03 | 12.0 - 15.0 | 16 .0 -1 8.0 | 2.0 -3.0 |

| 321 | ≤ 0 .08 | ≤1.0 | ≤2.0 | ≤0.035 | ≤ 0.03 | 9.0 - 13 .0 | 17.0 -1 9.0 | - |

| 630 | ≤ 0 .07 | ≤1.0 | ≤1.0 | ≤0.035 | ≤ 0.03 | 3.0-5.0 | 15.5-17.5 | - |

| 631 | ≤0.09 | ≤1.0 | ≤1.0 | ≤0.030 | ≤0.035 | 6.50-7.75 | 16.0-18.0 | - |

| 904L | ≤ 2 .0 | ≤0.045 | ≤1.0 | ≤0.035 | - | 23.0·28.0 | 19.0-23.0 | 4.0-5.0 |

| 2205 | ≤0.03 | ≤1.0 | ≤2.0 | ≤0.030 | ≤0.02 | 4.5-6.5 | 22.0-23.0 | 3.0-3.5 |

| 2507 | ≤0.03 | ≤0.8 | ≤1.2 | ≤0.035 | ≤0.02 | 6.0-8.0 | 24.0-26.0 | 3.0-5.0 |

| 2520 | ≤0.08 | ≤1.5 | ≤2.0 | ≤0.045 | ≤ 0.03 | 0.19 -0. 22 | 0. 24 -0 . 26 | - |

| 410 | ≤0.15 | ≤1.0 | ≤1.0 | ≤0.035 | ≤ 0.03 | - | 11.5-13.5 | - |

| 430 | ≤0.1 2 | ≤0.75 | ≤1.0 | ≤ 0.040 | ≤ 0.03 | ≤0.60 | 16.0 -18.0 | - |