Basic Info.

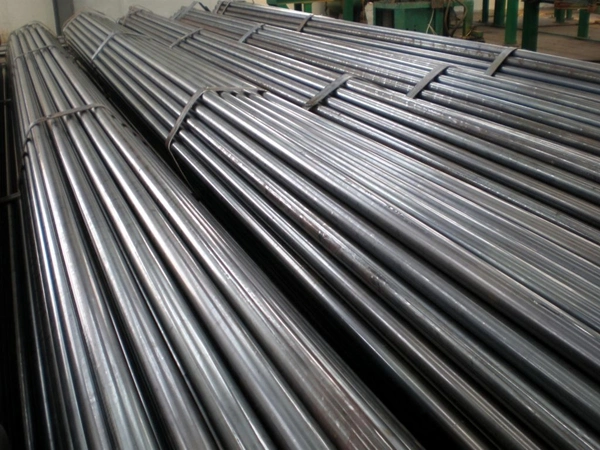

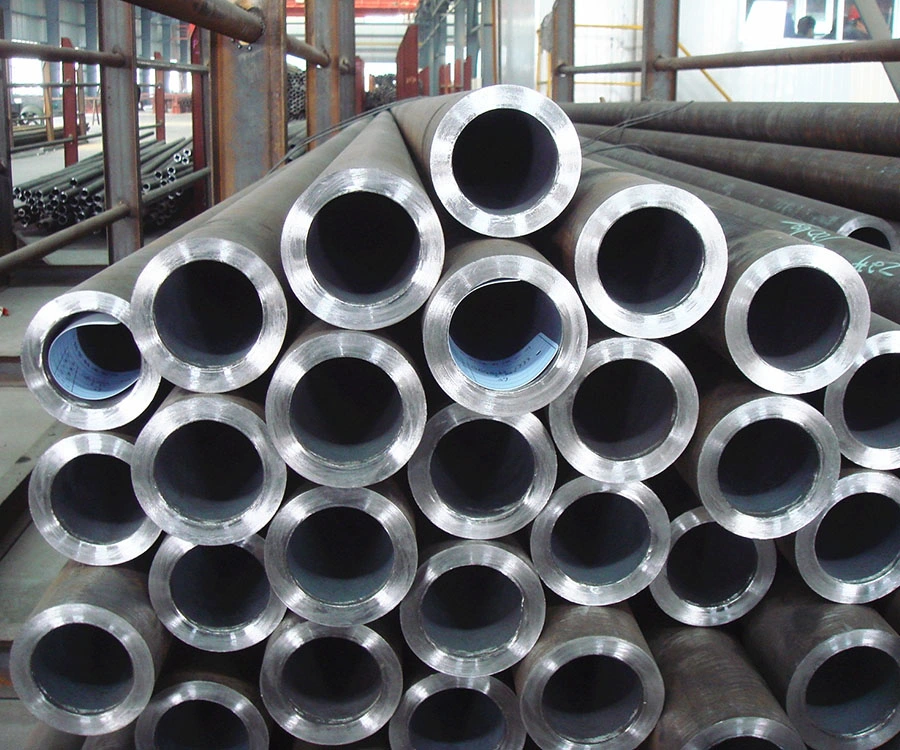

Product Description

Alloy steel pipe Standard & Material:

| GB5310-2013 Standard: 20G,25MnG, 15MoG,15CrMoG, 20MoG, 12CrMoG, 12Cr2MoG,12Cr1MoVG, 12Cr2MoWVTiB, 10Cr9Mo1VNb, 15CrMoG, 10CrMo910, ASTM A209M/AS-209M Standard A209T1/SA209 T1, A209 T1b/SA-209 T1b, A209T1a/SA209 T1a ASTM A213M/ASME SA 213 M Standard: T2, T5, T9, T11, T12, T22, T23, T24, T91, T911, T92, T122 ASTM A333M/ASME SA-333/SA333M Standard: Gr1, Gr3, Gr4, Gr6, Gr7,Gr8, Gr9, Gr10, Gr11 ASTM A335/ASME SA335 Standard: P1, P2, P5,P5b, P5c, P9, P11, P12,P21,P22,P23, P24, P91, P92 ASTM A519 Standard: 4118, 4130,4135,4137,4140 ASTM A691 Standard GRADE 91, CM65, CM70, CM75, CMSH70, CMS75, CMSH80, ASTM A691 Standard GRADE 1/2 Cr, GRADE 1CR, GRADE 1 1/4 CR, 2 1/4 Cr, 3CR, 5CR, 9 CR DIN17175 Standard: ST35.8, ST45.8, 15Mo3, 13CrMo44, 10CrMo910, 14MoV63,12Cr1MoV EN10216-2 Standard: P195GH, P235GH, P265GH, 13CrMo4-5, 10CrMo9-10, 16Mo3, 10CrMo5-5, X10CrMoVNb9-1 JIS G3458 Standard: STPA12, STPA20, STPA22, STPA23, STPA24, STPA25, STPA26 JIS G3441 Standard:SCR420 TK,SCM415 TK, SCM418 TK, SCM420TK, SCM430TK, SCM435TK, SCM440TK. NF A49-213/215 Standard: TU15D3, TU13CD4-04, TU10CD910, TUZ10CD505 Alloy C276 BS3059 Standard: S1-622-440, S2-622-440, S1-622-490, S2-622-490, S1-629-470, S2-629-470, S2-629-590 BS3604Standard: HFS625 CFS625 BS3606Standard: CFS625 |

| Description | Surface | black painted,PE coated,galvanized |

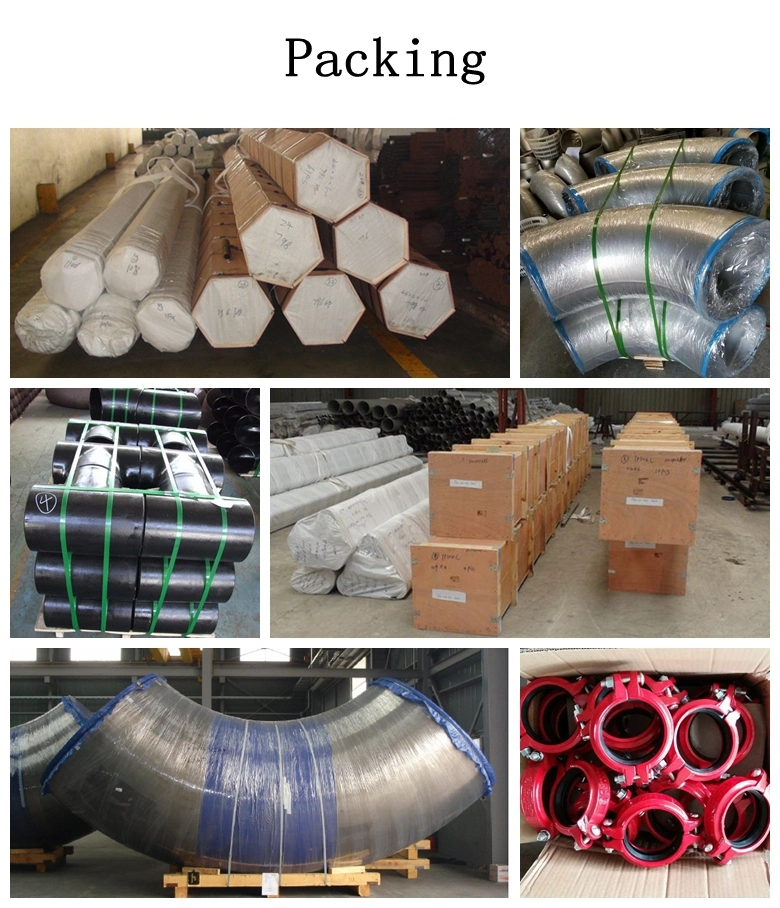

| Package | Standard export seaworthy package or as required. | |

| Application | Alloy steel pipe applies to petroleum,chemical industry, electric power, boiler, high temperature resistant, low temperature resistant,corrosion resistant seamless steel pipe used.Alloy steel pipealso can made according to the customer. | |

Chemical properties (%) | |||||||

Material | C | Si | Mn | P | S | Mo | Cr |

% | % | % | max | max | % | max | |

A335 P2/12CrMo | 0,10 - 0,20 | 0,10 - 0,30 | 0,30 - 0,61 | 0,025 | 0,025 | 0.44-0.65 | 0.5-0.81 |

A335 P5/Cr5Mo | max. 0,15 | max. 0,50 | 0,30 - 0,60 | 0,025 | 0,025 | 0,45-0,65 | 4,00-6,00 |

A335 P9/ Cr9Mo | max. 0.15 | 0.5-1.0 | 0.3-0.6 | 0.025 | 0.025 | 0.9-1.1 | 8-10 |

A335 P11/12CrMoV | 0,05 - 0,15 | 0,50 - 1,00 | 0,30 - 0,60 | 0,025 | 0,025 | 0,44-0,65 | 1,00-1,50 |

A335 P12/12CrMo | 0,05 - 0,15 | max. 0,50 | 0,30 - 0,61 | 0,025 | 0,025 | 0,44-0,65 | 0,80-1,25 |

A335 P22/ Cr2Mo | 0,05 - 0,15 | max. 0,50 | 0,30 - 0,60 | 0,025 | 0,025 | 0,87-1,13 | 1,90-2,60 |

A213 P91 | 0,08 - 0,12 | 0,20 - 0,50 | 0,30 - 0,60 | 0.02 | 0.01 | 0.85-1.05 | 8.00-9.50 |

Mechanical properties | |||

Material | Tensile N/mm2 | Strength Min. N/mm2 | Yield % min. |

A335 P2 | min. 380 | 205 | 30 |

A335 P5 | min. 415 | 205 | 30 |

A335 P9 | min.415 | 205 | 22 |

A335 P11 | min. 415 | 205 | 30 |

A335 P12 | min. 415 | 205 | 30 |

A335 P22 | min. 510 | 400 | 20 |

A213 P91 | min. 585 | 415 | 20 |