Basic Info.

Product Description

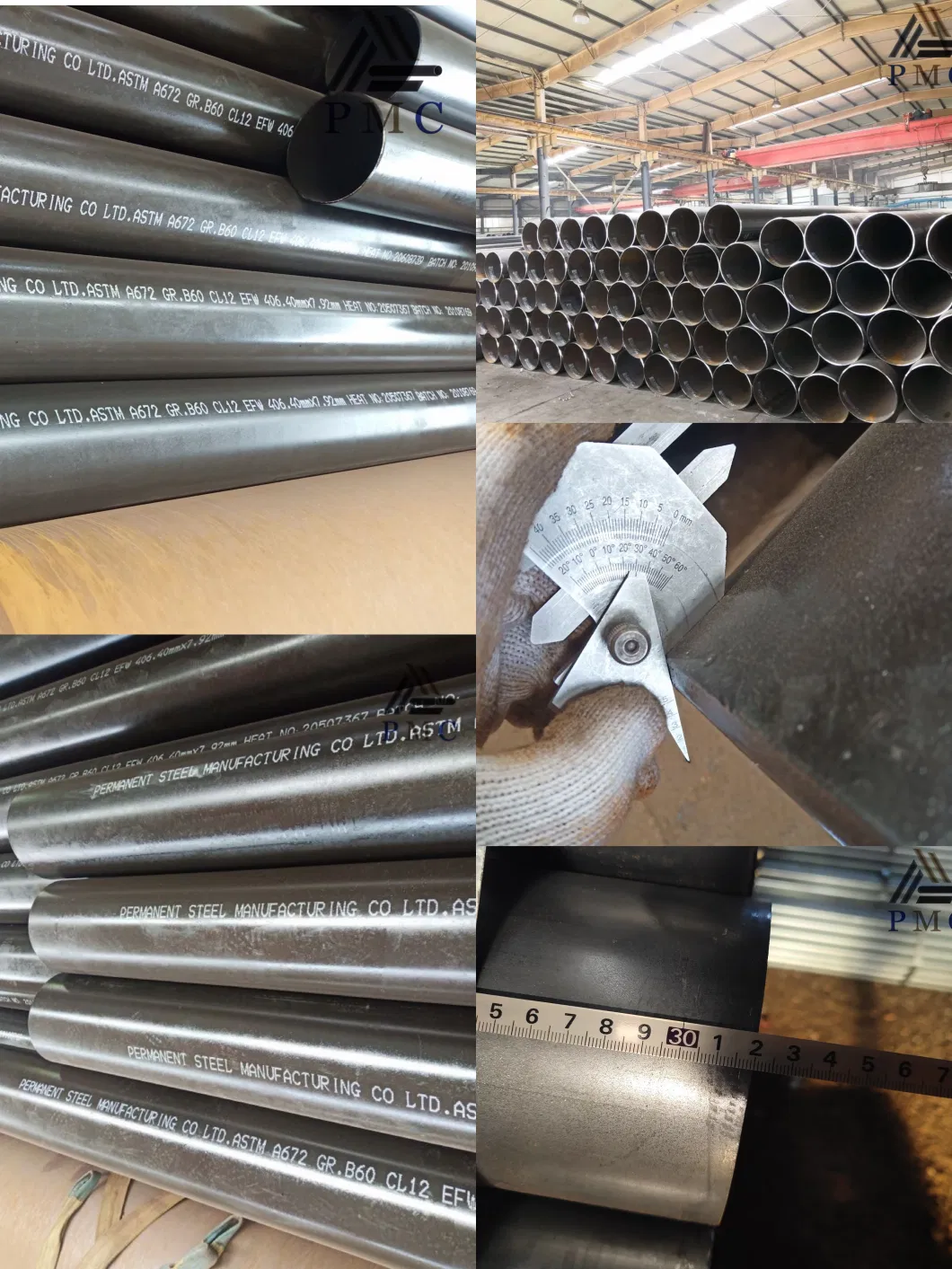

Product Description:

ERW tube is "high frequency resistance welded steel tube", which is different from the welding process of ordinary welded tube. The weld is made of the base material of the steel belt body, and the mechanical strength is better than that of ordinary welding.

ERW stands for resistance welding. Resistance welding is widely used in aviation, aerospace, energy, electronics, automotive, light industry and other industrial sectors because of its high production efficiency, low cost, material saving and easy automation. It is an important welding process

Straight seam high frequency welded pipe (ERW steel pipe) is formed by forming a hot-rolled coil through a forming machine. The skin effect and proximity effect of high-frequency current are used to heat and melt the edge of the pipe blank. Pressure welding is carried out under the action of a squeeze roller. Realize production. Welded steel pipes have simple production process, high production efficiency, many varieties and specifications, and less equipment, but their general strength is lower than seamless steel pipes.

Specification:

ERW Steel Pipe(Electric Resistance Welded Pipe), A53 ERW Pipe, ERW Carbon Steel Pipe

Sizes:

Out Diameter:1/2"-24"

Wall Thickness: 1.65-20mm

Length : 3-12m, or according to customer's requirement

End : Plain End, Beveled End, Treaded

ASTM 5L, ASTM A53, ASTM A178, ASTM A500/501, ASTM A691, ASTM A252, ASTM A672, EN 10217

Steel Grade:

API 5L: PSL1/PSL2 Gr.A, Gr.B, X42, X46, X52, X56, X60, X65, X70

ASTM A53: GR.A, GR.B

EN: S275, S275JR, S355JRH, S355J2H

GB: Q195, Q215, Q235, Q345, L175, L210, L245, L320, L360-L555

Uses:

For ERW Line Pipe

For ERW Casing

For ERW Structure Tube

For High pressure and high temperature

Surface: Lightly oiled, Hot dip galvanized, Electro galvanized, Black, Bare, Varnish coating/Anti rust oil, Protective Coatings (Coal Tar Epoxy, Fusion Bond Epoxy, 3-layers PE)

Packing: Plastic plugs in both ends, Hexagonal bundles of max. 2,000kg with several steel strips, Two tags on each bundle, Wrapped in waterproof paper, PVC sleeve, and sackcloth with several steel strips, Plastic caps.

Test: Chemical Component Analysis, Mechanical Properties (Ultimate tensile strength, Yield strength, Elongation), Technical Properties (Flattening Test, Bending Test, Hardness Test, Impact Test), Exterior Size Inspection, Hydrostatic Test, NDT TEST ( ET TEST, RT TEST, UT TEST)

Small diameter erw steel pipe

| Out diameter | Sch 5 | Sch 10 | Sch 40 | ||||

| Inch | mm | Thickness | Kg/mtr | Thickness | Kg/mtr | Thickness | Kg/mtr |

| 1/2" | 21.3 | 1.65 | 0.81 | 2.11 | 1.01 | 2.77 | 1.29 |

| 3/4" | 26.7 | 1.65 | 1.03 | 2.11 | 1.30 | 2.87 | 1.71 |

| 1" | 33.4 | 1.65 | 1.31 | 2.77 | 2.12 | 3.38 | 2.54 |

| 1 1/4" | 42.2 | 1.65 | 1.93 | 2.77 | 3.15 | 3.68 | 4.11 |

| 1 1/2" | 48.3 | 1.65 | 1.93 | 2.77 | 3.15 | 3.68 | 4.11 |

| 2" | 60.3 | 1.65 | 2.42 | 2.77 | 3.98 | 4.81 | 5.31 |

| 3" | 88.9 | 2.11 | 4.58 | 3.05 | 6.54 | 5.49 | 11.45 |

| 3 1/2" | 101.6 | 2.11 | 5.25 | 3.05 | 7.52 | 5.74 | 13.77 |

| 4" | 114.3 | 2.11 | 5.25 | 3.05 | 7.52 | 5.74 | 13.77 |

| 5" | 141.3 | 2.77 | 9.50 | 3.40 | 11.74 | 6.55 | 22.10 |

| 6" | 168.3 | 2.77 | 11.47 | 3.40 | 14.04 | 7.11 | 28.68 |

| 8" | 219.1 | 2.77 | 14.99 | 3.76 | 20.25 | 8.18 | 43.16 |

Large diameter erw steel pipe

| OD | WT | ||||||||

| Inch | mm | 8 5/8" | 219.1mm | 10 3/4" | 273.1mm | 12 3/4" | 325.0mm | 14" | 355.6mm |

| 0.157 | 4.0 | ||||||||

| 0.197 | 5.0 | ||||||||

| 0.236 | 6.0 | ||||||||

| 0.276 | 7.0 | ||||||||

| 0.315 | 8.0 | ||||||||

| 0.354 | 9.0 | ||||||||

| 0.394 | 10.0 | ||||||||

| 0.133 | 11.0 | ||||||||

| 0.492 | 12.5 | ||||||||

| 0.551 | 14.0 | ||||||||

| 0.630 | 16.0 | ||||||||

| 0.689 | 17.5 | ||||||||

| 0.748 | 19.0 | ||||||||

| 0.787 | 20.0 | ||||||||

Large diameter erw steel pipe

| OD | WT | ||||||||||

| Inch | mm | 16" | 406.4mm | 18" | 457.7mm | 20" | 508.0mm | 24" | 610mm | 24 4/5" | 630.0mm |

| 0.157 | 4.0 | ||||||||||

| 0.197 | 5.0 | ||||||||||

| 0.236 | 6.0 | ||||||||||

| 0.276 | 7.0 | ||||||||||

| 0.315 | 8.0 | ||||||||||

| 0.354 | 9.0 | ||||||||||

| 0.394 | 10.0 | ||||||||||

| 0.133 | 11.0 | ||||||||||

| 0.492 | 12.5 | ||||||||||

| 0.551 | 14.0 | ||||||||||

| 0.630 | 16.0 | ||||||||||

| 0.689 | 17.5 | ||||||||||

| 0.748 | 19.0 | ||||||||||

| 0.787 | 20.0 | ||||||||||

| STANDARDS | PRODUCTS | RANGES |

| IS:1239 (Part-I) | Mild Steel Tubes, Tubular | 15mm NB - 150mm NB |

| IS:1161 | Mild Steel Tubes for Structural purpose | 15mm NB - 200mm NB |

| IS:3601 | Mild Steel tubes for Mechanical & General Eng. purpose | 20mm x 0.80mm to 165.10 x 7.00 mm |

| IS:3589 | ERW Pipes for water Gas & Sewage | 168.3 x 4.00 mm to 219.1 x 7.00mm |

| IS:9295 | Steel Tubes for Idlers for Belt conveyors | 63.5 x 4.00 mm to 219.1 x 7.0 mm |

| IS:4270 | Steel Tubes for Water Wells | 114.3 x 5.00mm to 219.1mm x 7.1mm |

| IS:7138 | Steel Tubes for furniture | 20.0 x .60mm to 60.0 x 2.0mm |

| IS:4923 | Hollow Steel sections for structural purpose | 12.5 x 12.5 x 0.80 to 150 x 150 x 6.0mm 10 x 20 x 0.80mm to 150 x 200 x 6.0mm |

| IS:3074 | Steel Tubes for Automobile purpose | 19.7 x 1.00mm to 101.6 x 6.0mm |

| BS:1387 | Screwed & Socket Steel Tubes & Tubular | ½"NB to 6″NB 2.00 mm - 5.40 mm wall thick |

| BS:3601 | Steel Pipes & Tubes for pressure purpose | ½"NB to 6″NB 2.00 mm - 7.00 mm wall thickness |

| BS:6323 | Steel tubes for mechanical & general engineering purposes | 21.3″ to 219.1mm OD wall thickness-1.60-7.00 mm |

Latest project order:

About us:

1.Pipe:

Permanent Steel Manufacturing Co.,Ltd has been committed to being a major supplier of quality kinds of carbon steel pipe, stainless steel tube, hollow section numerous types of piping equipments including Bend, Cap, Coupling, Elbow, Reducer, Stub End, Tee, Olet, Joint, Gasket, etc.

The Products from Permanent Steel Manufacturing Co.,Ltd are supplied in accordance with appropriate International Standards as well as Customer Specifications in a large variety of steel grades and dimensions. Permanent Steel Manufacturing Co.,Ltd on a 250,000 m2 area and has three production units: Foundry, Rolling and Extrusion mills. Permanent Steel Manufacturing Co.,Ltd operates under strict quality, environmental, as well as health and safety management systems, in compliance with ISO 9001, ISO 14001 and OHSAS 18001 standards. We have six spiral pipe production lines have introduced into the international advanced technique design andmanufacturing,each of them is outfitted with the whole set equipment from uncoiling to pipeindpection,packing and then Ex-work,includingun coiler, leve ling ma chine , fly welding machine ,plasma cutting machine,pipe endgrinding machine,hydrostatic testing machine,beveling machine,end expander, ultrasonic inspector for pipe body and weld seam,highlyclear X-ray image inspection system and so on.

2.Coating:

We have two advanced three-layer PE anticorrosive pipe production lines, which can carry out three-layer PE and FBE anticorrosion for steel pipe with diameter of 20mm to 1820mm, as well as epoxy asphalt anticorrosion production line, steel-plastic composite pipe production line, internal and external plastic coating and plasticlining production line, and cement mortar production line for inner wall of steel pipe. The annual anticorrosion production capacity reaches 18 million square meters. Since its establishment, the company has formed a good cooperative relationship with many domestic and foreign steel pipe manufacturers, gas companies and oil companies, and its sales network covers many countries

.

Our team:

Our customer visit:

End Users:

Our advantage:

1. Full projects reference all of the world and vendor references from the most main oil and Gas in stitute, companies, investors

2. The inspection program is full supported to the docs requirements

3. The list of producing equipment and inspection equipment will be provided

4. The relative shipping docs, third party inspection report, Mill test certification, custom appreciate letters

5. The mill certification such as API monogram , ISO ect....

7. ITP, MPS & ISO manual

8. Prices competitively level

9. Full presentation experiences and guidance

10. Engineering design & construction capacities

11. Financial supports, various of payment term could be acceptable such as L/C, T/T.

12. Free custom inspection corporation & checked corporation in CCPIT

13. Full bank supported company with a perfect line of Credit "AAAAA"

ect

FAQ

Q: How long is your delivery time?

A: Depends on pipes size and quantity. 7-10 days for stocked steel pipe and 20-40 days for new productions according to quantity.bowl shape stainless steel smoking pipe screens

Q: Do you provide samples? Is it free or extra? 201 Stainless Steel Pipe used for Food and Chemical Industry

A: Yes,we could offer free steel pipe sample for your evaluation. stainless steel pipe fitting

Q: What is your terms of payment? steel pipe

A: TT payment way, TT+LC, or 100% sight LC and usance L/C for 30-120days,the specific payment should be addressed by further discussion.