- Overview

- Product Description

- Product Parameters

- Detailed Photos

- Product Application

- Packaging & Shipping

- Certifications

- Our Service

Basic Info.

Product Description

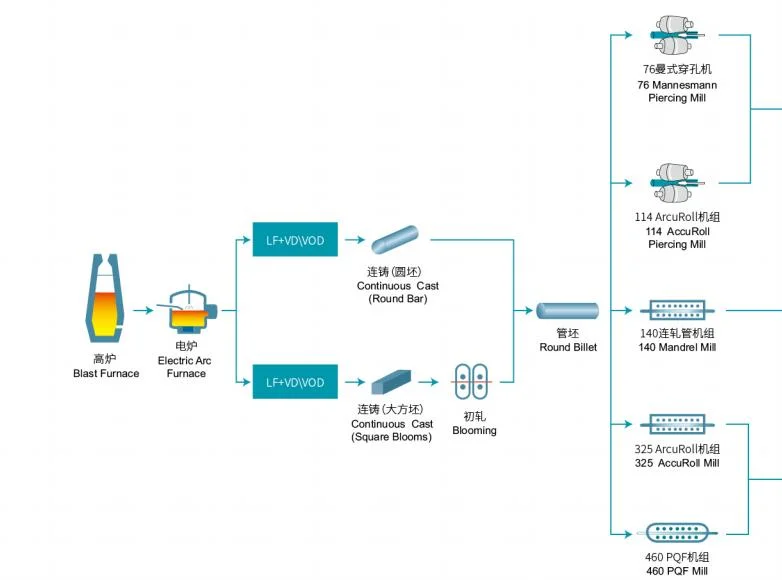

Steel Boiler Pipe is a type of seamless steel pipe that is specifically designed to withstand high pressure and temperatures in boiler and heat exchanger applications. It is made from high-quality carbon steel or alloy steel and is often used in power plants, refineries, and other industrial settings. Steel Boiler Pipe is available in various grades and sizes, and can be customized to meet the specific needs of different applications. With its superior strength, durability, and resistance to corrosion, Steel Boiler Pipe is a reliable and cost-effective solution for demanding industrial environments.

ASTM A335 Pipe (ASME S/A335, Chorme-Moly) is a seamless ferritic Alloy-Steel Pipe for high temperature service. Pipe ordered to this specification shall be suitable for bending, flanging (vanstoning), and similar forming operations, and for fusion welding. Sometimes referred to as "P Grade", Chrome Moly Pipe is popular in P-Grades P5, P9, P11, P22, and P91. The most common use of grades P11, P22, and P91 is in the power industry and petro-chemical plants, Grades P5 and P9 are commonly used in refineries.

A335 is often called chrome moly pipe because of the chemical makeup of Molybdenum (Mo) and Chromium (Cr). Molybdenum increases the strength of steel as well as the elastic limit, resistance to wear, impact qualities, and hardenability. Moly increases the resistance to softening, restrains grain growth and makes chromium steel less susceptible to embrittlement. Moly is the most effective single additive that increases high temperature creep strength. It also enhances the corrosion resistance of steel, and inhibits pitting. Chromium (or chrome) is the essential constituent of stainless steel. Any steel with 12% or more Chrome is considered stainless. Chrome is virtually irreplaceable in resisting oxidation at elevated temperatures. Chrome raises the tensile, yield, and hardness at room temperatures. The composition chrome moly alloy steel pipe make it ideal for use in power plants, refineries, petro chemical plants, and oil field services where fluids and gases are transported at extremely high temperatures and pressures.

| Product Name | High Pressure boiler tube Galvanized Seamless Steel Tube for Boiler steam pipe |

| Material | Mo Steel, Cr-Mo Steel, Cr- Mo-W Steel |

| industry | Baosteel |

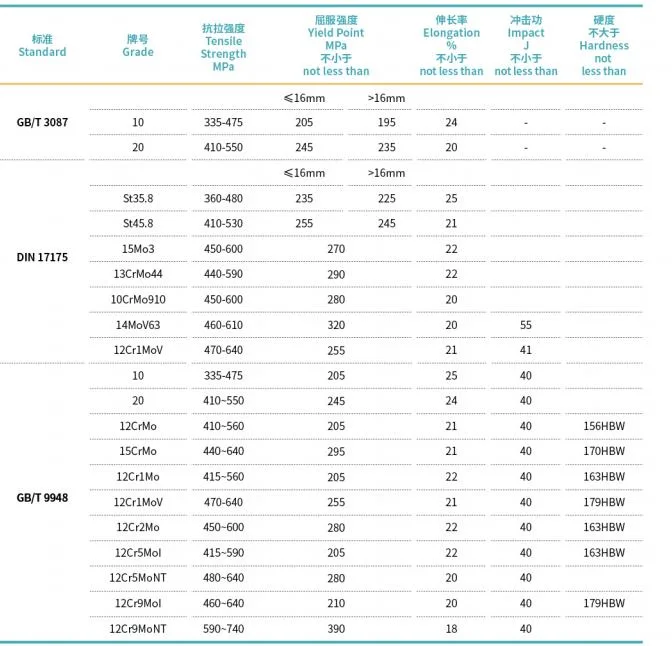

| Standard | ASME SA-106, ASME SA-192M. ASME SA-209M. ASME SA-210M.ASTM A 106M. ASTE A192M.EN 10216-2. DIN 17175, JIS G 3456. JIS G 3461. JIS G 3462 |

| Grade | SA-106B, SA-192. SA-210A1, SA-106C, SA-210C. SA-209T1. SA-213 T11. |

| Uses | For manufacture wall panel, economizer, reheater,superheater and steam pipeline of boilers |

| Steel Grade: | 106B,210A1,210C,P9,P11,T1,T11,T2,T5,T12,T22,T23,T91,T92,P235GH,13CrMo4-5,15Mo3,10CrMo9-10, ST35.8,ST45.8,STB340,STBA 12-2,API5L,5CT 304,304L,309S,310S,316,316L,317,317L,321,347,347H,304N,316L, 316N,201,202,S32205,S31803 |

| Standard: | ASME/ASTM SA/A53/513/106/209/210/213/335/178/179/519 ASME/ASTM SA/A213,A312,A269,A778,A789, DIN 17456, DIN17457,DIN 17459,DIN17175,EN10216,BS3605,BS3059 JIS G3458,JISG3459,JIS G3461,JIS G3462,JIS G3463 |

| Specification: | Outdiameter 10~508mm |

| Wt: | 1.0-30mm,or according to customer's special request |

| Length: | 2-20meters,or according to customer's special request |

| Package: | Export Standard Package |

| Typies of tube: | Boiler tube,precision tube,mechanical tubing,cylinder tube,line pipes,etc |

| Mill MTC: | Supplied before shipment |

| Inspection: | The Third Party inspection can be accepted,SGS,BV,TUV |

| Mount port: | Any port in China |

| Trade Term: | FOB,CIF,CFR,EXW,etc. |

| Price Term: | TT or LC at sight |

| Our services: | We can customized according to customer's requriement or drawing ,packaging according to customers' request |

| ASTM A179/(ASME SA179) | |

| Seamless Cold Drawn Low Carbon Steel Heat Exchanger And Conderser Tubes | |

| Application: | For tubular heat exchangers,condensers,and similar heat transfer apparatus. |

| Size(mm): | O.D.:6.0~114.0 W.T.:1~15 L:max 12000 |

Grade and Chemical Composition (%)

| Chemical Composition | C | Mn | P≤ | S≤ | Si≤ |

| 0.06-0.18 | 0.27-0.63 | 0.035 | 0.035 | 0.25 |

Tolerance(SA-450/SA-450M):

| OD In (mm) | + | - | WT In(mm) | + | - |

| <1(25.4) | 0.10 | 0.10 | ≤1.1/2(38.1) | 20% | 0 |

| 1~1.1/2(25.4~38.1) | 0.15 | 0.15 | >1.1/2(38.1) | 22% | 0 |

| >1.1/2~<2(38.1~50.8) | 0.20 | 0.20 | |||

| 2~<2.1/2(50.8~63.5) | 0.25 | 0.25 | |||

| 2.1/2~<3(63.5~76.2) | 0.30 | 0.30 | |||

| 3~4(76.2~101.6) | 0.38 | 0.38 | |||

| >4~7.1/2(101.6~190.5) | 0.38 | 0.64 | |||

| >7.1/2~9(190.5~228.6) | 0.38 | 1.14 |

ASTM A192/A192M-02 | |

| Seamless Carbon Steel Bolier Tubes for High-Pressure | |

| Application: | For seamless carbon steel bolier and superheater tubes for high-pressure service |

| Size(mm): | O.D.:6.0~114.0 W.T.:1~15 L:max 12000 |

Grade and Chemical Composition (%)

| Chemical Composition | C | Mn | P≤ | S≤ | Si≤ |

| 0.06-0.18 | 0.27-0.63 | 0.035 | 0.035 | 0.25 |

Tolerance(SA-450/SA-450M):

| OD In (mm) | + | - | WT In(mm) | + | - |

| <1(25.4) | 0.10 | 0.10 | ≤1.1/2(38.1) | 20% | 0 |

| 1~1.1/2(25.4~38.1) | 0.15 | 0.15 | >1.1/2(38.1) | 22% | 0 |

| >1.1/2~<2(38.1~50.8) | 0.20 | 0.20 | |||

| 2~<2.1/2(50.8~63.5) | 0.25 | 0.25 | |||

| 2.1/2~<3(63.5~76.2) | 0.30 | 0.30 | |||

| 3~4(76.2~101.6) | 0.38 | 0.38 | |||

| >4~7.1/2(101.6~190.5) | 0.38 | 0.64 | |||

| >7.1/2~9(190.5~228.6) | 0.38 | 1.14 |

Adequate inventory, Good quality, Strict testing, Quick delivery, High -quality service!

Any demand for the steel boiler tube, welcome to inquiry us online!