- Overview

- Product Description

- Chemical Composition (%)

- Mechanical property

- Product specification

- Packaging & Shipping

- FAQ

Basic Info.

Product Description

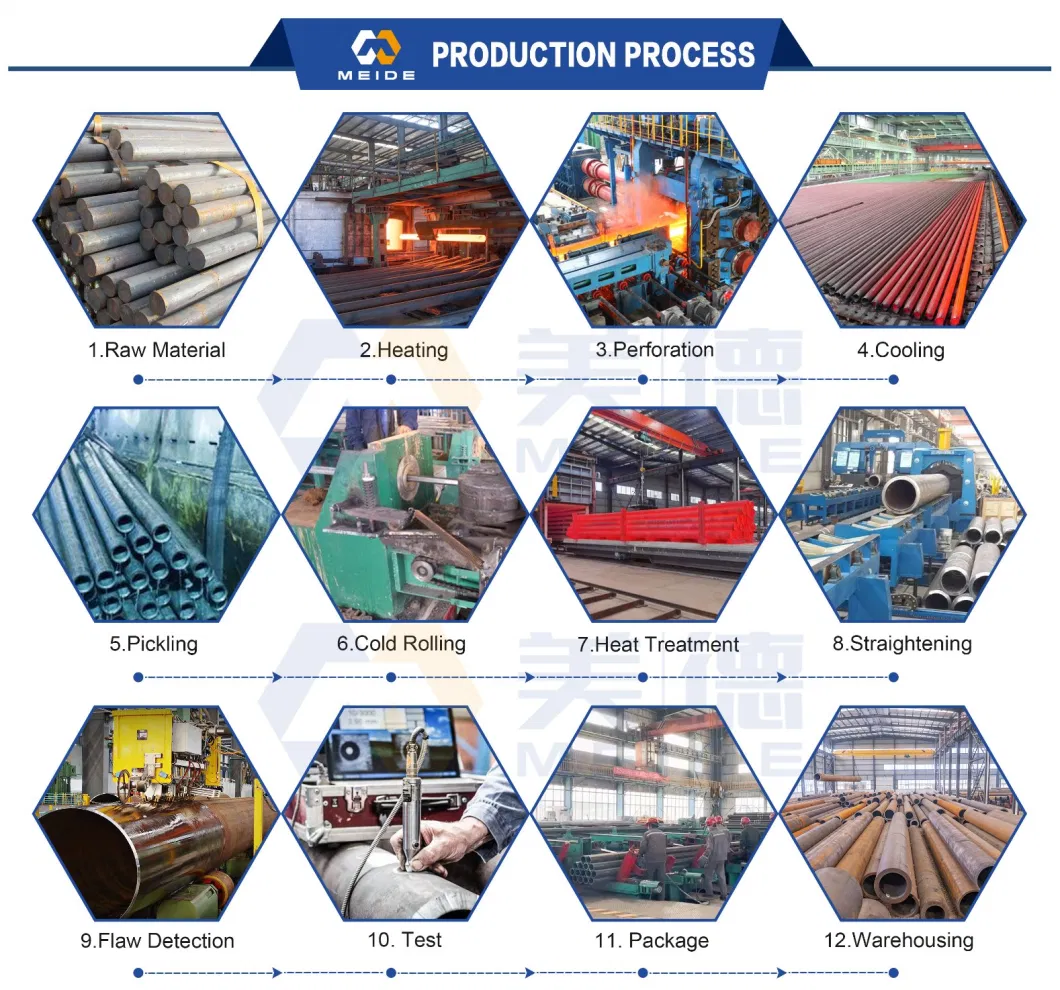

1. Technology of Hot Rolled, Cold Rolled or Cold drawn.

1. Technology of Hot Rolled, Cold Rolled or Cold drawn.2. Hollow cross-section with lighter weight and higher pressure.

3. High hardness, strength, wear resistance and anti-corrosion.

4. The SMLS can becut, threaded or grooved. And the coating method includes black / red lacquer, varnish painting, hot dip galvanization, etc.

| Type | ASTM A106 black painted steel seamless alloy pipe steel tube | |

| ExecutiveStandard | ASTM A53/ASTM A106/API 5L GR.B | |

Size | Outer Diameter | Seamless:17-914mm 3/8"-36" |

| Wall Thickness | 2-60mm SCH10 SCH20 SCH30 STD SCH40 SCH60 XS SCH80 | |

| Length | 1-12m as customer requirement | |

| Ends | Plain end/Beveled,protected by plastic caps on both ends, cut quare,grooved,threaded andcoupling,etc. | |

| Surface Treatment | Bare,Painting black,varnished,galvanized,anti-corrosion 3PE PP/EP/FBE coating | |

| Technical Methods | Hot-rolled/Cold-drawn/Hot-expanded | |

| Testing Methods | Pressure test,Flaw detection,Eddy current testing, Hydrostatic testing or Ultrasonic examination and also with chemical and physical property inspection | |

| Third Party Inspection | SGS BV MTC | |

| Trade Terms | FOB CIF CFR | |

| Payment Terms | FOB 30%T/T,70% before shipment CIF 30% pre-payment and the balance to be paid upon B/L (copy) or Irrevocable 100% L/C at sight | |

| Material | C | Si | Mn | P | S | Cr | Ni | Cu | Mo |

| ASTM 4119 GB 12CrMo | 0.08-0.15 | 0.17-0.37 | 0.4-0.7 | 0.035 | 0.035 | 0.4-0.7 | 0.3 | 0.3 | 0.4-0.55 |

| JIS SCM415 GB 15CrMo | 0.12-0.18 | 0.17-0.37 | 0.4-0.7 | 0.035 | 0.035 | 0.8-1.1 | 0.3 | 0.3 | 0.4-0.55 |

| ASTM 4118 GB 20CrMo | 0.17-0.24 | 0.17-0.37 | 0.4-0.7 | 0.035 | 0.035 | 0.8-1.1 | 0.3 | 0.3 | 0.15-0.25 |

| ASTM 4130 GB 30CrMo | 0.26-0.34 | 0.17-0.37 | 0.4-0.7 | 0.035 | 0.035 | 0.8-1.1 | 0.3 | 0.3 | 0.15-0.25 |

| ASTM 4135 GB 35CrMo | 0.32-0.4 | 0.17-0.37 | 0.4-0.7 | 0.035 | 0.035 | 0.8-1.1 | 0.3 | 0.3 | 0.15-0.25 |

| ASTM 4140 GB 42CrMo | 0.38-0.45 | 0.17-0.37 | 0.5-0.8 | 0.035 | 0.035 | 0.9-1.2 | 0.3 | 0.3 | 0.15-0.25 |

| ASTM 4142 GB 42CrMnMo | 0.4-0.45 | 0.15-0.35 | 0.78-1 | 0.035 | 0.04 | 0.8-1.1 | 0.25 | 0.35 | 0.15-0.25 |

| Material | Diameter of sample d mm | Heat treatment or condition. | Tensile strength σb Mpa | Point of yield σs Mpa | Ratio of elongation δ % | Reduction of section ψ % | hardness HBW | Shock absorption energy KV2 J |

| ASTM 4119 GB 12CrMo | d=30 | Quenching + tempering | ≥410 | ≥265 | ≥24 | ≥60 | ≤179 | ≥110 |

| JIS SCM415 GB 15CrMo | d=30 | Quenching + tempering | ≥440 | ≥295 | ≥22 | ≥60 | ≤179 | ≥94 |

| ASTM 4118 GB 20CrMo | d=15 | Quenching + tempering | ≥885 | ≥685 | ≥12 | ≥50 | ≤197 | ≥78 |

| ASTM 4130 GB 30CrMo | d=25 | Quenching + tempering | ≥930 | ≥785 | ≥12 | ≥50 | ≤229 | ≥63 |

| ASTM 4135 GB 35CrMo | d=25 | Quenching + tempering | ≥980 | ≥835 | ≥12 | ≥45 | ≤229 | ≥63 |

| ASTM 4140 GB 42CrMo | d=25 | Quenching + tempering | ≥1080 | ≥930 | ≥12 | ≥45 | ≤217 | ≥63 |

| DN | OD | ASTM A53 / API 5L / ASTM A795 | BS1387 / EN10255 | |||||

| SCH10S | STD SCH40 | SCH80 | Light | Medium | Heavy | |||

| MM | INCH | MM | MM | MM | MM | MM | MM | |

| 15 | 21.3 | 1/2" | 2.11 | 2.77 | 3.73 | 2 | 2.6 | - |

| 20 | 26.7 | 3/4" | 2.11 | 2.87 | 3.91 | 2.3 | 2.6 | 3.2 |

| 25 | 33.4 | 1" | 2.77 | 3.38 | 4.55 | 2.6 | 3.2 | 4 |

| 32 | 42.2 | 1-1/4" | 2.77 | 3.56 | 4.85 | 2.6 | 3.2 | 4 |

| 40 | 48.3 | 1-1/2" | 2.77 | 3.68 | 5.08 | 2.9 | 3.2 | 4 |

| 50 | 60.3 | 2" | 2.77 | 3.91 | 5.54 | 2.9 | 3.6 | 4.5 |

| 65 | 73 or 76 | 2-1/2" | 3.05 | 5.16 | 7.01 | 3.2 | 3.6 | 4.5 |

| 80 | 88.9 | 3" | 3.05 | 5.49 | 7.62 | 3.2 | 4 | 5 |

| 90 | 101.6 | 3-1/2" | 3.05 | 5.74 | 8.08 | |||

| 100 | 114.3 | 4" | 3.05 | 6.02 | 8.56 | 3.6 | 4.5 | 5.4 |

| 125 | 141.3 | 5" | 3.4 | 6.55 | 9.53 | 5 | 5.4 | |

| 150 | 168.3 | 6" | 3.4 | 7.11 | 10.97 | 5 | 5.4 | |

| 200 | 219.1 | 8" | 3.76 | 8.18 | 12.7 | |||

| 250 | 273.1 | 10" | 4.19 | 9.27 | 15.09 | |||

1. Bundle and pack.

2. Warning for inclined end or flat end or according to buyer's requirements.

3. Marking: According to customer requirements.

4. Apply varnish.

5. Plastic covers at both ends.

Q1:who are we?

A:We are based in Shandong, China, start from 2022,sell to North America(60.00%),Western Europe(14.00%),South America(6.00%).

There are total about 11-50 people in our office.

Q2. how can we guarantee quality?

A:Always a pre-production sample before mass production;

Always final Inspection before shipment;

Q3.what can you buy from us?Which ports are accepted for delivery?

A:Copper,Aluminum,Mould steel, Seamless carbon steel,Precision steel pipe,The steel plate,Alloy steel,Titanium,Custom machine parts.It can be delivered from Qingdao, Tianjin, Shanghai, Guangzhou and other ports.

Q4.why should you buy from us not from other suppliers?

A:Shandong Meide Import and Export Co., Ltd. has 25 years of production experience. With advanced precision production equipment

and modern large warehouses, has a stockpile of 200,000 tons of goods, has a number of long-term stable cooperative customers.

Q5.what services can we provide?

A:Accepted Delivery Terms: FOB,CFR,CIF,EXW;

Accepted Payment Currency:USD,EUR,JPY,CAD,AUD,HKD,GBP,CNY,CHF;

Accepted Payment Type: T/T,L/C,D/P D/A,PayPal;

Language Spoken:English,Chinese

Q6.Can we get the some samples?Any charges?

A:Yes,you can get available samples in our stock.Free for real samples,but customers need to pay the freight cost.

Q7.How can we get your price ?

A:We need below information to quote for you:

1). Product Name

2). Standard

3). Material Grade (Chemical Composition)

4). Dimension

5). Quantity

6). The Drawing for Special Parts