Basic Info.

Product Description

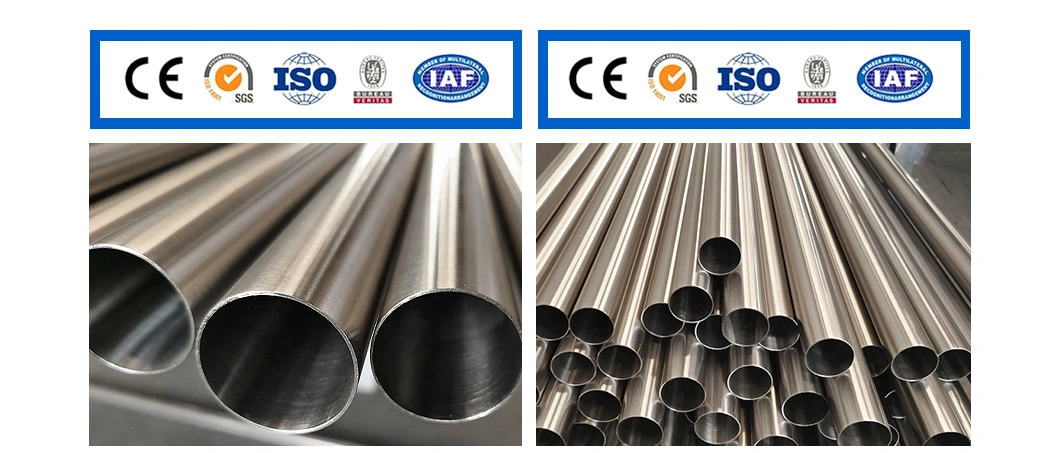

Nickel-chromium-iron inconel alloy is a standard engineering material for applications which require resistance to corrosion and heat. The alloy also has excellent mechanical properties and presents the desirable combination of high strength and good workability.

The alloy is used extensively in the chemical industry for its strength and corrosion resistance. Applications include heaters, stills, bubble towers and condensers for processing of fatty acids; evaporator tubes, tube sheets and flaking trays for the manufacture of sodium sulfide; and equipment for handling abietic acid in the manufacture of paper pulp.

| Diameter | Φ 6 to Φ 406mm |

| Thickness | 0.3-150mm,(SCH10-XXS) |

| Length | 2000mm, 2500mm, 3000mm, 5800mm, 6000mm,12000mm,etc |

| Standard | ASTM,JIS, AISI, GB, DIN, EN |

| Surface | BA,2B,NO.1,NO.4,4K,HL,8K |

| Application | It is widely used in high-temperature and electric industry, medical devices, construction, chemistry, food industry, agriculture, and ship components. It also applies to food and beverage packaging, kitchen supplies, trains, aircraft, conveyor belts, vehicles, bolts, nuts, springs, and screen mesh etc. |

| Certification | ISO, SGS |

| Technique | Cold Rolled Hot Rolled |

| Edge: | Mill Edge \ Slit Edge |

| Quality | SGS Inspection |

| DIN/EN | UNS No | International name | Component | |

| 1 | 2.406 | N02000 | Nickl200 | 99Ni-0.15Fe-0.2Mn-0.1Si-0.1Cu-0.1C |

| 2 | 2.4601 | N02201 | Nickl201 | 99Ni-0.15Fe-0.2Mn-0.1Si-0.1Cu-0.01C |

| 3 | 2.405 | N02270 | Nickl270 | 99.9Ni-0.02Fe-0.001Mn-0.002Si-0.005Cu-0.01C |

| 4 | 1.498 | S66286 | INCOLOY Alloy A286 | 25Ni-15Cr-1.5Mo-2Ti-1Mg-0.03C |

| 5 | N08367 | INCOLOY Alloy 25-6HN | 25Ni-20Cr-6.3MO-0.25Cu-0.2N-0.01P-0.05S-0.01C | |

| 6 | 1.4529 | N08926 | INCOLOY Alloy 25-6Mo | 25Ni-20Cr-6.5Mo-1Cu-0.2N-1.0Mg-0.01P-0.005S-0.01C |

| 7 | 2.446 | N08020 | INCOLOY Alloy 20 | 36Ni-21Cr-3.5Cu2.5Mo-1Mn-0.01C |

| 8 | 1.4563 | N08028 | INCOLOY Alloy 28 | 32Ni-27Cr-3.5Mo-1Cu-0.01C |

| 9 | 1.4886 | N08330 | INCOLOY Alloy 330 | 35Ni-18Cr-2Mg-1SI-0.03C |

| 10 | 1.4876 | N08800 | INCOLOY Alloy 800 | 32Ni-21Cr-0.3~1.2(Al+Ti)0.02C |

| 11 | 1.4876 | N08810 | INCOLOY Alloy 800H | 32Ni-21Cr-0.3~1.2(Al+Ti)0.08C |

| 12 | 2.4858 | N08825 | INCOLOY Alloy 825 | 42Ni-21Cr-3Mo-2Cu-0.8Ti-0.1AI-0.02C |

| 13 | 2.4816 | N06600 | Inconel Alloy 600 | 72Ni-151Cr-8Fr-0.2Cu-0.02C |

| 14 | 2.4851 | N06601 | Inconel Alloy 601 | 60Ni-22Cr-1.2Al-0.02C |

| 15 | 2.4856 | N06625 | Inconel Alloy 625 | 58Ni-21Cr-9Mo-3.5Nb-1CO-0.02C |

| 16 | 2.4856 | N06626 | Inconel Alloy 625LCF | 58Ni-21Cr-9Mo-3.5Nb-1CO-0.02C |

| 17 | 2.4606 | N06686 | Inconel Alloy 686 | 57Ni-21Cr-16Mo-4W-0.01C |

| 18 | 2.4642 | N06690 | Inconel Alloy 690 | 58Ni-30Cr-9Fe-0.2Cu-0.02C |

| 19 | 2.4668 | N07718 | Inconel Alloy 718 | 52Ni-19Cr-5Nb-3Mo-1Ti-0.6Al-0.02C |

| 20 | 2.4669 | N07750 | Inconel Alloy 750 | 70Ni-15Cr-6Fe-2.5Ti-0.06Al-1Nb-0.02C |

| 21 | 2.436 | N04400 | MONEL400 | 63Ni-32Cu-1Fe-0.1C |

| 22 | 2.4375 | N05500 | MONEL K-500 | 63Ni-30Cr-1Fe-3Al-0.6Ti-0.1C |

| 23 | 2.4819 | N10276 | Hastelloy C-276 | 57Ni-16Mo-16Cr-5Fe-4W-2.5Co-1Mn-0.35V-0.08Si-0.01C |

| 24 | 2.461 | N06455 | Hastelloy C-4 | 65Ni-16Cr-16Mo-0.7Ti-3Fe-2Co-1Mn-0.08Si-0.01C |

| 25 | 2.4602 | N06022 | Hastelloy C-22 | 56Ni-22Cr-13Mo-3Fe-2.5Co-0.5Mn-0.35V-0.08Si-0.01C |

| 26 | 2.4675 | N06200 | Hastelloy C-2000 | 59Ni-23Cr-16Mo-1.6Cu-0.08Si-0.01C |

| 27 | 2.4665 | N06002 | Hastelloy X | 47Ni-22Cr-18Fe-9Mo-1.5Co-0.6W-0.1C-1mn-1Si-0.008B |

| 28 | 2.4617 | N10665 | Hastelloy B-2 | 69Ni-28Mo-0.5Cr-1.8Fe-3W-1.0Co-1.0Mn-0.01C |

| 29 | 2.466 | N10675 | Hastelloy B-3 | 65Ni-28.5Mo-1.5Cr-1.5Fe-3W-3Co-3Mn-0.01C |

| 30 | N06030 | Hastelloy G-30 | 43Ni-30Cr-15Fe-5.5Mo-2.5W-5Co-2Cu-1.5Mn-0.03C | |

| 31 | N06035 | Hastelloy G-35 | 58Ni-33Cr-8Mo-2Fe-0.6Si-0.3Cu-0.03C | |

| 32 | 1.4562 | N08031 | Nicrofer hMo31 | 31Ni-27Cr-6.5Mo-1.2Cu-2mn-0.01C |

| 33 | 2.4605 | N06059 | Nicrofer hMo59 | 59Ni-23Cr-16Mo-1.0Fe-0.01C |

Widely Application Range Help You Overcome Tough ProjectsOur metal products are widely used in industrial electric furnaces, civil nuclear power, power station boilers, petrochemical industry, aerospace, ships, automobiles, machinery, communication electronics, instruments for the application of high resistance, high temperature, corrosion resistance, heat resistance, wear resistance, fatigue, creep and other use environment. We provide customers with scientific solutions and excellent product service from the material perspective.

Complete Set of Manufacturing and Testing Equipment Guarantee the Stable Supply and Product QualityWe have production lines from vacuum smelting, electroslag remelting, forging, to hot rolled, machining, heat treatment, cold rolled, cold drawn, etc. The main equipment includes 1T vacuum smelting furnace, 0.6T vacuum consumable furnace, 0.5T to 3T electroslag remelting furnace, 5T electrohydraulic hammer, 2T forging air hammer, etc.Our Group is equipped with advanced physical and chemical testing equipment, including chemical analysis, spectral analysis, ultrasonic testing, mechanical testing, high temperature tensile testing, impact testing, hardness testing, bending testing, metallographic analysis and other testing equipment. We have strong professional technical force and new product research and development capabilities. We have applied for 20 patents, obtained six invention patents and more than 10 utility model patents.

Our goal is to improve quality, and our guarantee is to optimize detection. Analyze the chemical composition of the finished product, strictly control the materials, test the mechanical properties and conduct one-by-one inspection of the chemical properties of the finished product, as well as eddy current and ultrasonic non-destructive testing according to standard requirements to ensure product quality.The inspector will inspect the internal and external surfaces, shape, length, outer diameter, thickness, etc. of the finished product according to the technical conditions and requirements of the corresponding product standards to meet customer requirements.

Our Group provides customers with high-quality products and services with advanced equipment, strong technical strength and a high sense of social responsibility. Our products have been exported globally, including Germany, France, the United States, Japan, Russia, ltaly, Turkey, the United Arab Emirates, Australia, Saudi Arabia, Ukraine, Thailand, Viet-nam, Singapore, Spain, lreland, India, South Africa, Mexico, etc.

We sincerely hope to establish a long-term and extensive strategic partnership with our customers for mutual benefit and common development!