- Overview

- Product Specification

- Other Product Details

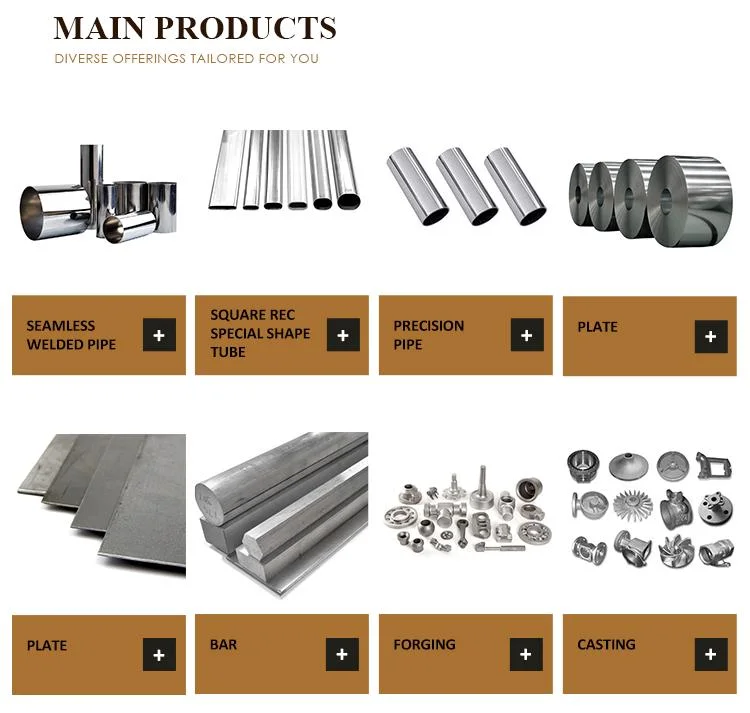

- Product Display

- Company Profile

- Certifications

- Customer Feedback

- FAQ

Basic Info.

Product Description

ASTM A519 Standard Specification for Seamless Carbon and Alloy Steel Mechanical Tubing

ASTM A519 covers several grades of carbon and alloy steel seamless mechanical tubing. The standard is also acceptable in the manufacture of piping. It is manufactured by hot working and then cold finishing the steel into round, square, rectangle or special shapes.

Chemical Requirements of ASTM A519 Carbon Steel

Grade Designation | Chemical Composition Limits, % | |||

Carbon | Manganese | Phosphorus, max | Sulfur, max | |

1010 | 0.08-0.13 | 0.30-0.60 | 0.05 | |

1020 | 0.18-0.23 | 0.30-0.60 | 0.04 | 0.05 |

1026 | 0.22-0.28 | 0.60-0.90 | 0.04 | 0.05 |

1035 | 0.32-0.38 | 0.60-0.90 | 0.04 | 0.05 |

1045 | 0.43-0.50 | 0.60-0.90 | 0.04 | 0.05 |

Mechanical Property of ASTM A519 Carbon Steel

Carbon Steel Grade | Tensile Strength (MPa) | Yield Strength (MPa) | Elongation (in 50 mm) |

1010 | 325 (47,000 psi) | 260 (37,500 psi) | 20% |

1020 | 420 (60,900 psi) | 350 (50,800 psi) | 15% |

1026 | 490 (71,000 psi) | 415 (60,200 psi) | 15% |

1035 | 510 (74,000 psi) | 370 (53,700 psi) | 15% |

1045 | 600 (87,000 psi) | 450 (65,300 psi) | 12% |

Chemical Requirements of ASTM A519 Alloy Steel

Grade | Chemical Composition Limits, % | |||||||

Carbon | Manganese | Phosphorus, max | Sulfur, max | Silicon | Nickel | Chromium | Molybdenum | |

4130 | 0.28-0.33 | 0.40-0.60 | 0.04 | 0.04 | 0.15-0.35 | - | 0.80-1.10 | 0.15-0.25 |

4140 | 0.38-0.43 | 0.75-1.00 | 0.04 | 0.04 | 0.15-0.35 | - | 0.80-1.10 | 0.15-0.25 |

Mechanical Property of ASTM A519 Alloy Steel

Alloy Steel Grade | Tensile Strength (MPa) | Yield Strength (MPa) | Elongation (in 50 mm) | Reduction of Area | Brinell Hardness |

4130 | Approximately 670 (97,000 psi) | Approximately 435 (63,100 psi) | 25.50% | 59.50% | 197 |

4140 | Approximately 860 (125,000 psi) | Approximately 660 (95,500 psi) | 25.70% | 56.90% | 223 |

ASTM A519 Seamless Carbon and Alloy Steel Mechanical Tubing Advantages

Wide Material Selection: ASTM A519 covers a range of carbon steel and alloy steel grades, meeting various mechanical and heat treatment requirements.

High Mechanical Performance: These tubes often exhibit excellent strength, hardness, and toughness, making them suitable for applications requiring high strength and wear resistance.

Superior Surface Quality: Due to their manufacturing process, these seamless tubes typically have a smooth, consistent surface suitable for machining and aesthetically demanding applications.

Reliable Toughness: For alloy steels like 4130 and 4140, they offer the advantage of good toughness across a range of temperatures, especially in aviation applications.

Ease of Heat Treatment: Many steels under the ASTM A519 standard can undergo various heat treatments, such as quenching, tempering, and annealing, to achieve the desired mechanical properties.

Strict Quality Control: ASTM standards often require rigorous quality control and testing to ensure the quality and performance of the tubes meet specified requirements.

Diverse Dimensions: These tubes offer options in various wall thicknesses, diameters, and lengths to fit a variety of designs and applications.

Corrosion Resistance: While this largely depends on the specific alloy composition, many alloy steels, especially when they undergo appropriate heat treatment and/or coatings, offer some degree of corrosion resistance.

Product Specification of ASTM A519 Mechanical Tubing

Jiangsu HYT stocks a full range of ASTM A519 carbon and alloy steel pipe in:

Standard: ASTM A519

Material Grades: 1010, 1020, 1026, 1035, 1045, 4130, 4140

Outer Diameters: NPS 2" to 12"

Wall Thickness: Schedules 120 through XXH

Range of Length: 20ft to 40ft, 5.8m to 11.8m, 6m to 12m.

Ends procession: Plain, beveled, threaded

Contact Jiangsu HYT for ASTM A519 Carbon and Alloy Steel Pipe and Tube Today

Our extensive inventory at HYT covers A519 in multiple different forms and all grades. To find out more about how we can assist with your specific application, please contact us to receive a custom quote and to learn more about our shipping and pick-up options.

| Brand | HYT |

| Origin | China |

| Application Industry | Oil and Gas, Construction, Water Supply and Treatment, Automotive, Power Generation, etc. |

| Surface Treatment | Pickling, Passivation, Electropolishing, Sandblasting, Coating or Painting, PVD, CVD, Plating, Heat Treatment, Hot Dip Galvanizing, Surface Polish, Surface Finish, black, varnishing, antiseptical, oiled, etc. |

| Surface Finish | NO.1, 2D, 2B, BA (Bright Annealed), NO.3, NO.4, HL (Hair Line), NO.7, NO.8, SATIN. |

| Color | Silver (Natural Steel), Black (Coated or Oxidized), Galvanized (Zinc), Green (Coated), Blue (Coated), Red (Coated), Yellow (Coated), White (Coated). |

| Pipe Ends | Plain End (PE), Beveled End (BE), Threaded End (TE), Grooved, Bell End, Tapered, Expanded. |

| Tolerance | As standards' Requirements |

| Test | Support Third-party Test. |

| Certification | GB/T19001-2016/ISO9001:2015 GB/T24001-2016/ISO14001:2015 GB/T 45001-2020/ISO 45001:2018 |

| Processing Service | Cutting, Bending, Threading, Welding, Grooving, Coating, Drilling, Galvanizing, Heat Treatment, Punching. |

| Sample | Free Sample Available |

| Stock Status | Continuous Supply Of Spot Products |

| MOQ | 1 Ton |

| Packaging | Bundled, Wooden Cases, Plastic Wrapping, Plastic Caps, Palletized, Shrink Wrapped, Plastic Bagged, Steel Crates, Loose, Boxed. |

| Port | Shanghai |

| Delivery Term | EXW, FOB, FCA, etc. |

| Delivery Time | 3-5 days for the regular models, and 7 to 10 working days for the special sizes and processing |

| Payment Term | T/T, L/C, D/P, etc. |

| Customization | Customization Available |

Wide Application Range Help You Overcome Tough ProjectsOur metal products are widely used in industrial electric furnaces, civil nuclear power, power station boilers, petrochemical industry, aerospace, ships, automobiles, machinery, communication electronics, instruments for the application of high resistance, high temperature, corrosion resistance, heat resistance, wear resistance, fatigue, creep and other use environment. We provide customers with scientific solutions and excellent product service from the material perspective.

Jiangsu HYT International Trading Co., LTD.HYT, founded in 2015, is a wholly-owned subsidiary of Wuxi Lusheng Special Steel Co, Ltd which is responsible for overseas sales and market exploitation of various kinds of steel pipes. Our Group, certified by ISO and SGS, is a high-tech enterprise integrating research, development, production and sales of steel products made of stainless steel, carbon steel and alloy steel. HYT owns independent steel mills which can meet customers' requirements on the quality, quantity, precision and customization of steel products.

Achieving the ISO 9001:2015 Certification is just one example of HUI YOU TONgs' dedication to quality and continuous improvement. Each employee is responsible for understanding company expectations and adhering to the procedures of our Quality Management System.

Achieving the ISO 9001:2015 Certification is just one example of HUI YOU TONgs' dedication to quality and continuous improvement. Each employee is responsible for understanding company expectations and adhering to the procedures of our Quality Management System.

Complete Set of Manufacturing and Testing Equipment Guarantee the Stable Supply and Product QualityWe have production lines from vacuum smelting, electroslag remelting, forging, to hot rolled, machining, heat treatment, cold rolled, cold drawn, etc. The main equipment includes 1T vacuum smelting furnace, 0.6T vacuum consumable furnace, 0.5T to 3T electroslag remelting furnace, 5T electrohydraulic hammer, 2T forging air hammer, etc.Our Group is equipped with advanced physical and chemical testing equipment, including chemical analysis, spectral analysis, ultrasonic testing, mechanical testing, high temperature tensile testing, impact testing, hardness testing, bending testing, metallographic analysis and other testing equipment. We have strong professional technical force and new product research and development capabilities. We have applied for 20 patents, obtained six invention patents and more than 10 utility model patents.

Adequate Factory Inventory Guarantees Stable Supply ChainJiangsu HYT has a large amount of steel stock in factory which is available for delivery. Right now, steel coil, steel pipe, steel plate, steel bar, steel profile of common size are stocked in warehouse. These good quality steel product would be delivered to your factory quickly after complete transaction.

Since 2015, HYT has actively cooperated with many domestic steel mills. HYT regularly exchange steel technology with these mills and make progress from this. ln the process of communicating with customers, we carefully listen to customers' requirements and produce steel products as customers' demands. Under necessary circumstances, HYT is willing to help customers find suitable steel mill to produce some special products to save time and cost for customers because we have the reliable resources of still mills to prevent you to be cheated.

Since 2015, HYT has actively cooperated with many domestic steel mills. HYT regularly exchange steel technology with these mills and make progress from this. ln the process of communicating with customers, we carefully listen to customers' requirements and produce steel products as customers' demands. Under necessary circumstances, HYT is willing to help customers find suitable steel mill to produce some special products to save time and cost for customers because we have the reliable resources of still mills to prevent you to be cheated.