Basic Info.

Section Shape

Round

Grade

Gr B, X42,X46, X56, X60,X65,X70

Surface

Black Painting, Varnish Painting, Bare Pipe, Oiled

Transport Package

Bundles with Strips, Loading Belt, Loose

Specification

customerized

Trademark

PMC

Origin

Cn

Production Capacity

800000ton/Year

Product Description

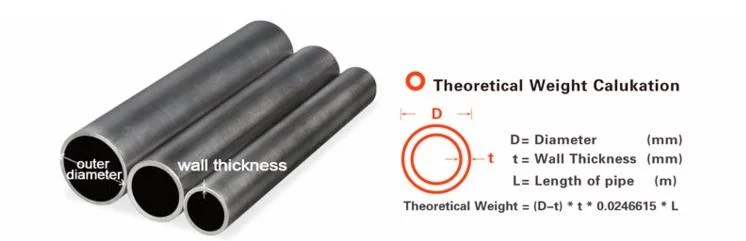

PRODUCT DATA:

| Product name | Electric Resistance Welding Steel Pipes |

| Outer diameter | 21.3mm(1/2")- 660mm(26") |

| Wall thickness | 0.8-25mm |

| Length | 3-18m( adjustable according to client's requirement) |

| Standard | API 5L, API 5CT, ASTM A106/A53, ASTM A519, JIS G 3441, JIS G3444,JIS G3445 DIN 2391, EN10305, EN10210, ASME SA106, SA192, SA210, SA213, SA335, DIN17175, ASTM A179… |

| Grade | API 5L : Gr.B, X42, X46, X56, X60, X65, X70 ASTM A53: Gr.A, Gr.B, Gr.C EN: S275, S275JR, S355JRH, S355J2H |

| Surface treatment | Black painting, Varnish painting, bare pipe, Oiled, Hot dip galvanized |

| End | Beveled end,plain end meet your need |

| Package | 1. big diameter: in loose 2. small diameter:packaged in bundles with strips 3. as per clients' requirement |

| Usage | Used for low pressure liquid delivery, such as water,nature gas and oil or for the construction pipe like piling pipes. |

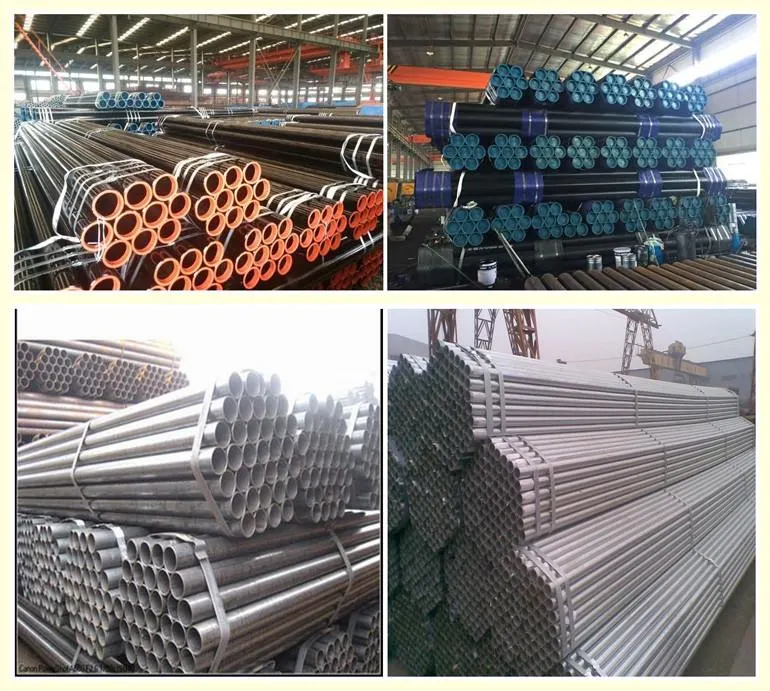

ERW STEEL PIPE PICTURE:

SIZE FOR ERW Steel Pipes :

| Wall Thickness | Out Diameter | ||||||||||||||||||

| Inch | mm | inch | mm | inch | mm | inch | mm | inch | mm | inch | mm | inch | mm | inch | mm | inch | mm | inch | mm |

| 8 5/8 | 219.1 | 10 3/4 | 273.1 | 12 3/4 | 325.0 | 14 | 355.6 | 16 | 406.4 | 18 | 457.7 | 20 | 508.0 | 24 | 610 | 24 4/5 | 630.0 | ||

| 0.157 | 4.0 | ||||||||||||||||||

| 0.197 | 5.0 | ||||||||||||||||||

| 0.236 | 6.0 | ||||||||||||||||||

| 0.276 | 7.0 | ||||||||||||||||||

| 0.315 | 8.0 | ||||||||||||||||||

| 0.354 | 9.0 | ||||||||||||||||||

| 0.394 | 10.0 | ||||||||||||||||||

| 0.433 | 11.0 | ||||||||||||||||||

| 0.492 | 12.5 | ||||||||||||||||||

| 0.551 | 14.0 | ||||||||||||||||||

| 0.630 | 16.0 | ||||||||||||||||||

| 0.689 | 17.5 | ||||||||||||||||||

| 0.748 | 19.0 | ||||||||||||||||||

| 0.787 | 20.0 | ||||||||||||||||||

TOLERANCE OF OUT DIAMETER:

| Standard | Out Diameter | Tolerance of Pipe End | Tolerance of Pipe Body |

| API 5L | 219.1~273.1 | +1.6mm, -0.4mm | ±0.75% |

| 274.0~320 | +2.4mm, -0.8mm | ±0.75% | |

| 323.9~457 | +2.4mm, -0.8mm | ±0.75% | |

| 508 | +2.4mm, -0.8mm | ±0.75% | |

| 559~610 | +2.4mm, -0.8mm | ±0.75% | |

| GB/T 9711-1 ISO 3183-1 | 219.1~273.1 | +1.59mm, -0.4mm | ±0.75% |

| 219.1~273.1 | 2.38mm, -0.79mm | ±0.75% | |

| 219.1~273.1 | 2.38mm, -0.79mm | ±1% | |

| 219.1~273.1 | 2.38mm, -0.79mm | ±1% | |

| GB/T 9711-2 ISO 3183-2 | 219.1~273.1 | ±0.5% | ±0.75% |

| 323.9~355.6 | ±1.6mm | ±0.75% | |

| 406.4~610 | ±1.6mm | ±3.0mm |

TOLERANCE OF WALL THICKNESS:

| Standard | Grade | Out Diameter | Wall Thickness | Tolerance |

| API 5L | / | 219.1~457 | 4~20 | +15%, -12.5% |

| B | 508~610 | 4~20 | +17.5%, -12.5% | |

| X42-X80 | 508~610 | 4~20 | +19.5%, -8% | |

| GB/T 9711-1 ISO 3183-1 | - | 219.1~457 | 4~20 | +15%, -12.5% |

| L245 | 508~610 | 4~20 | +17.5mm, -10% | |

| L290-L555 | 508~610 | 4~20 | +19.5%, -8% | |

| GB/T 9711-2 ISO 3183-2 | - | 219.1~610 | 4~20 | +1.0mm, -0.5mm |

| - | 219.1~610 | 10.1~20 | +10%, -5% |

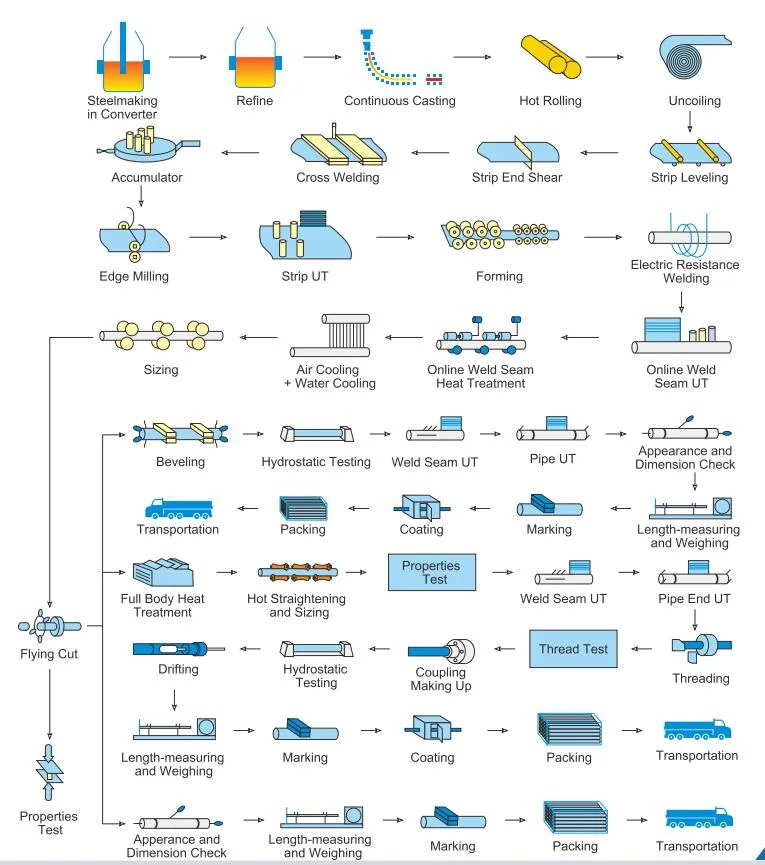

PRODUCTION PROCESS OF ERW STEEL PIPE:

PRODUCTION EQUIPMENT:

INSPECTION EQUIPMENT:

ERW steel pipe application:

Line pipe

Standard: API SPEC 5L, GB/T 97 11-1,GB/T 9711-2, ISO 3183-1, ISO 3193-2Application: for conveying gas, water and oil in both the oil and natural gas industries.

Structure tube

Standard: ASTM A53,GB/T 13793, GB/T 6275, JIS G 3466

Application: suitable for mechanical and pressure applications and low presure liquid delivery and other purpose.

COMPANY PROFILE:

Permanent Steel Manufacturing Co.,Ltd has been committed to being a major supplier of quality kinds of carbon steel pipe, stainless steel tube, hollow section, numerous types of piping equipment including Bend, Cap, Coupling, Elbow, Reducer, Stub End, Tee, Olet, Joint, Gasket, etc.As a factory,which specializing in the production, processing and sales of various steel pipes and pipe fittings size enterprises, headquartered in Hunan, the production base is located in Shandong and Tianjin. So far, the facility occupies more than 228,000 square feet under roof and includes two working mills and quality assurance chemical- and strength-testing laboratories on site and located on a 2,000-acre site with more than 60 acres under roof, is home to one of the world's largest cupolas; and the Contiarc, the first-of-its-kind continuous arc furnace.Our company has imported the advanced productive equipment and the inspection equipment, we will do the UT testing, RT testing on line, and the Hydrostatic testing during the production.

PACKAGE AND DELIVERY:

OUR SOME PROJECT:

FAQ:

Q: Are you trading company or manufacturer?

A: We are a sino-Singapore joint venture group company which have our own invest company.

Q: How long is your delivery time?

A: Depends on pipes size and quantity. 7-10 days for stocked steel pipe and 20-40 days for new productions according to quantity.bowl shape stainless steel smoking pipe screens

Q: Do you provide samples? Is it free or extra? 201 Stainless Steel Pipe used for Food and Chemical Industry

A: Yes,we could offer free steel pipe sample for your evaluation. stainless steel pipe fitting

Q: What is your terms of payment? steel pipe

A: 20%+80% T/T or 100% irrevocable L/C at sight, the specific payment should be addressed by further discussion.