- Overview

- Product Description

- Detailed Photos

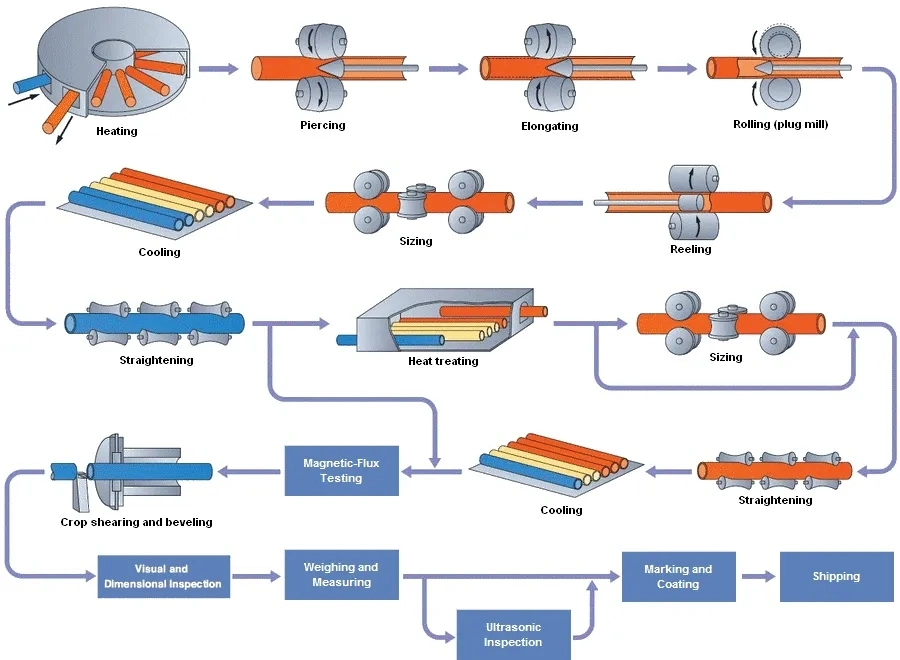

- Production process

- Packaging & Shipping

- customers

- Our Advantages

- Certifications

- FAQ

Basic Info.

Product Description

Sa213 T2 Boiler Tube Suppliers at dealer price.

ASME SA213 T2 Tube is used in in power generation, nuclear reactors, heat exchangers, boilers and in other high pressure and high temperature applications. Multi Metals (India) is a leading ASME SA213 T2 Tube manufacturer and supplier. Our products are of high quality and we offer some competitive pricing. The material has carbon, chromium, manganese, molybdenum, phosphorus, sulfur and silicon in the composition. The chromium and molybdenum additions make this low carbon steel ductile, strong and corrosion resistant in general corrosive applications and in mild acids. The minimum tensile strength of the ASME SA213 Gr T2 Tube is 415MPa and the minimum yield strength is 205MPa. These are similar values to the 304 and 316 grades of steels. But this carbon steel is harder and tough with a Brinell hardness score of 163HB max. There are different standards according to the ASME, ASTM and API standards with the ASME SA213 specification enabling the tubes for pressure vessel applications. The Asme Sa213 T2 Tubing is suitable to go with boilers, heat exchangers, super heaters, condensers and in oil and gas line applications. There are different dimensions to the tubes with 6.35mm to 101.6mm outer diameter range, ½ inches to 5 inches size range and different schedules ranging from sch40 to XXS and all schedules. The Sa213 Grade T2 Tube has wall thicknesses ranging up to 12mm. These seamless tubes can be made in different forms and shapes depending on the application requirements such as round, square, rectangular and hydraulic types. The ASME SA213 T2 Alloy Steel Tube comes in single random, double random, cut to length sizes up to 12m in length. Please contact us for specific information on the ASME SA213 T2 Alloy Steel Seamless Tube and the pricing.

| C, % | Mn, % | P, % | S, % | Si, % | Cr, % | Mo, % |

| 0.10-0.20 | 0.30-0.61 | 0.025 max | 0.025 max | 0.10-0.30 | 0.50-0.81 | 0.44-0.65 |

We help you to save your cost by providing exact size of ASTM A213 T2 Alloy Steel Tube

| Tensile Strength , MPa | Yield Strength, MPa | Elongation, % | Hardness, HB |

| 415 min | 205 min | 30 min | 163 max |

Alloy Steel T2 Tubes Outside Diameter & Tolerance :

| Outside Diameter | OD Tolerance | WT Tolerance | Ovality Tolerance | Cut Length Tolerance |

| OD≤ 12, 7 mm | ± 0, 13 mm | ± 15 % | - | + 3, 18 mm, - 0 mm |

| 12, 7 mm < OD ≤ 38, 1 mm | ± 0, 13 mm | ± 10 % | max, 1, 65 mm | + 3, 18 mm, - 0 mm |

| 38, 1 mm < OD ≤ 88, 9 mm | ± 0, 25 mm | ± 10 % | max, 2, 41 mm | + 4, 76 mm, - 0 mm |

Materials and Manufacture:

The Steel shall be killed.

The Tubes shall be made by the seamless process and shall be either hot-finished or cold finished, as specified.

Heat Treatment

Ferritic Alloy and Ferritic Stainless Steels - The ferritic alloy and ferritic stainless steels shall be reheated for heat treatment in accordance with the requirements of Standard. Heat treatment shall be carried out separately and in addition to heating for hot forming.

1. Materials: Take the raw materials out of the raw material warehouse or procurement channels, and conduct inspection and sorting;

2, temperature control: according to the required performance of the product, choose the appropriate temperature, and control it within a certain range;

3. Heating: Use hot blast stove or other heating methods to heat raw materials to the required temperature;

4, annealing: the heated raw materials into the torch box for annealing treatment, in order to improve the mechanical properties of raw materials;

5. Hot rolling: Put the heated raw materials into the hot rolling mill, and process the raw materials through pressure to obtain the required products;

6, cooling: hot rolled products with water or other coolant for cooling, to ensure the stability of the product structure;

7, detection: physical and chemical performance test to determine whether it meets the requirements;

8. Finishing: Organize the products, label them, and prepare them for loading and delivery.

- Oil and Gas Drilling

- Catering to domestic or industrial needs

- conveyance of fluids intended for critical high temperatures

- general corrosion service applications

- heat transfer process equipment like Boilers, Heat Exchangers

- General Engineering and Process Instrumentation applications

Baowu Aluminum (Shandong) Co., Ltd. is located in Dongchangfu county, which is the largest aluminum manufacturing county in north China. The factory is only one kilometer from the Jiliao expressway, which make our transportation more convenient. Our total investment is more than one billion yuan for two large factories. The factory covers an area of 120, 000 Square Meters and The company employs more than 500 staff, including over 60 engineering technicians. Our annual output capacity is more than 120, 000 tons of aluminium profiles. Baowu has been awarded the honorary titles of "China Patent Shandong Star Enterprise", "Key Enterprise of Shandong Architectural Profile Industry", "Famous Brand of the Province Construction Machinery Industry", "Shandong Famous Brand", "Well-known Trade Mark of Shandong Province", "China Energy-saving Product Certification", etc. Our company was appraised as a national medium-sized enterprise by the Agricultural Ministry of China in 2004. As a professional aluminum profiles manufacturer, we specialized in manufacturing building door and window, decoration, curtain wall and industrial aluminum profiles.

We have imported advanced manufacturing, checking and testing equipment of aluminum profiles from USA, Germany, Japan, Italy and Switzerland. With advanced checking and testing method and perfect quality guarantee system, our products are produced in strict accordance with the GB/5237 standard and have passed the qualification of ISO9001: 2000 International Quality Management System, ISO14001: 2004 Environmental Management System, 18000: 2001 Occupational Health Management System and 8000: 2001 Social Responsibility Management system. Meanwhile, we provides our customer with many kinds of finishes, such as sand blasting, polishing, brush, anodizing, electrophoresis, ceramic electrophoresis, sparkling electroporesis, powder coating, thermal insulation, fluorocarbon spraying (PVDF COATING), wood grain, etc. With stable product quality and perfect after-sales service, Baowu has been recognized as qualified supplier by lots of domestic famous enterprises such as Country Garden, Haier, Goertek, etc. Our aluminum profiles have been exported to many countries, such as USA, Brazil, Vietnam, India, South Korea, Australia, Germany, Kenya, Russia, Israel, Japan, etc.

Q:How do you control quality?

A:Mill test certification is supplied with shipment,third party inspection is avaliable.

Q:What are the advantages of your company?

A:We have many professionals,technical personnel,more competitive prices and best after-sales service than other stainless steel companies

Q:How many coutries you already exported?

A:Exported to more than 50 countries mainly from Arab, Kuwait, Egypt, Turkey, Jordan, Brazil, India, Indonesia, Korea, etc

Q:Can you provide sample?

A:Small sample in store and can provide the sample for free.Customized samples will take about 5-7days

Q:Why should you buy from us not from other suppliers?

A:Diversified products, direct supply from manufacturer.

Q:What is your terms of payment ?

A:we accept T/T ,L/C ,D/A,D/P, Western union, paypal ,The payment method can be negotiated by both parties according to the actual situation.

Please Please leave your enquiry in the message box at the bottom of the product page and click SEND, we will contact you as soon as possible!