Basic Info.

Model NO.

IR-B

Size

30mm~416mm

Length

Fixed Length, by Random

End Processing

Plain Ends

Surface

Bare Pipe, Anti-Rust Painting

Steel Material

St52, Q345b, 27simn, 15CrMo, 40cr, etc

Transport Package

Standard Seaworthy Packing

Specification

ASTM, DIN, GB/T

Trademark

Iron&steel

Origin

China

HS Code

73045910

Production Capacity

2000tons Per Month

Product Description

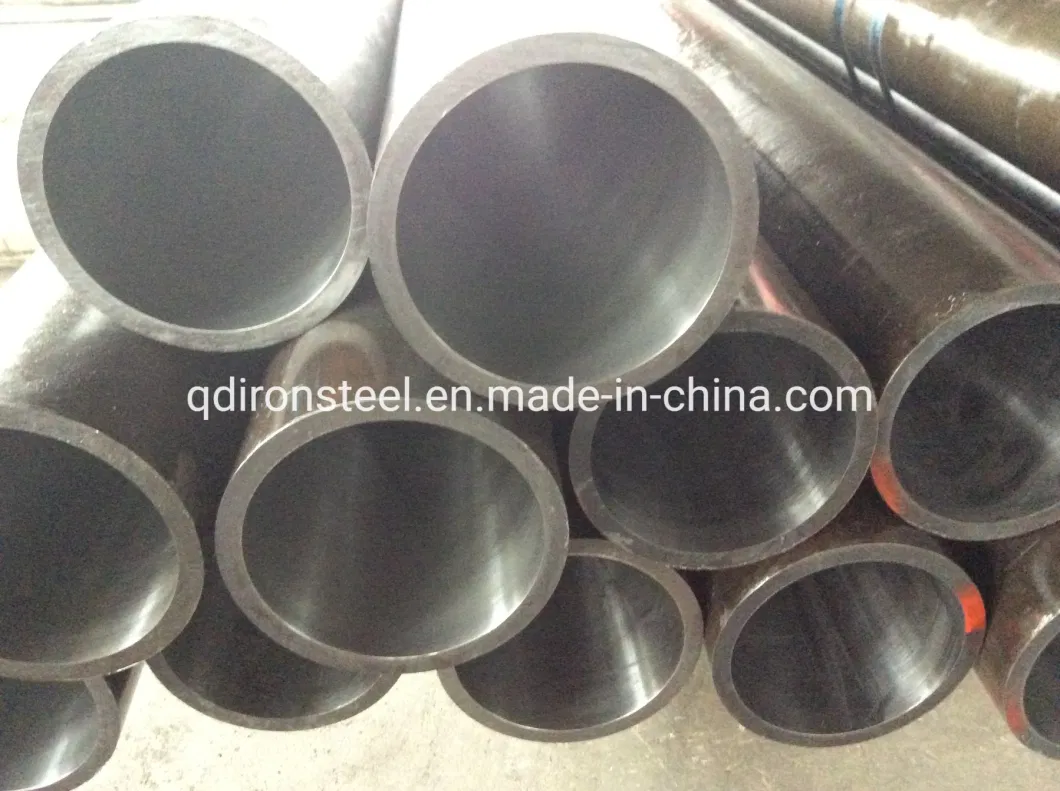

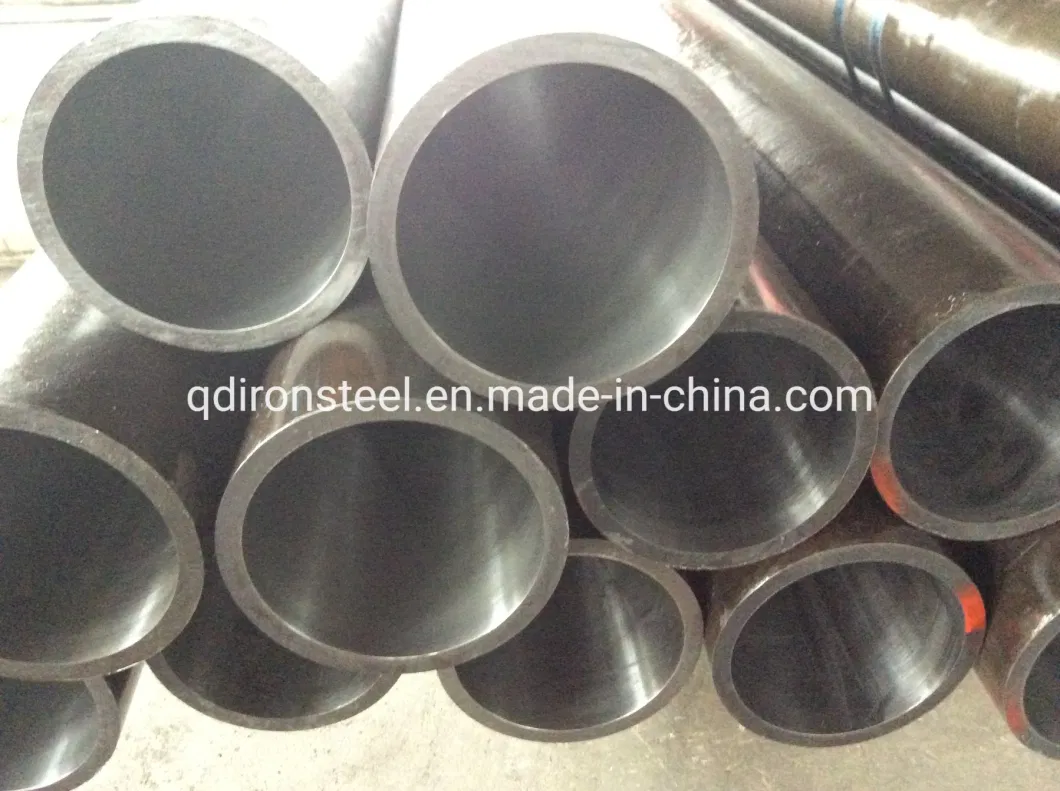

High precision honing pipe can be produced according to the demands of costumers that the degree of precision can reach H8/H9. Burnishing and honing service can be provided depending on the roughness requirement of inner diameter.

The honing pipe is used for the hydraulic cylinder making.

Used as the pipes on the heated side of low and medium pressure boilers(normally with operating pressure not higher than 5.88Mpa and

operating temperature below 450 oc);as the pipes on the heated sides of high·pressure boilers,economizers,overheaters,reheaters and pipes

for petrochemical industry(with the operating pressure above 9.8Mpa and operating temperature ranging between 450~C~650~C

Specifications of major steel material:

Tolerance of ID and WT

Length and cut tolerance

Length ≤ 500mm , +2mm

> 500mm ≤ 2000mm, +3mm

> 2000mm ≤ 5000mm, +5mm

> 2000mm ≤ 7000mm, +10mm

Standard:DIN 2391,EN10305

Material: St45,St52,E355

Chemical composition

9. Mechanical Properties

Tube ends

Tube ends shall be cut nominally square to the axis and free from burs

11.Delivery condition:BKS

Appearance

Tube shall have a smooth internal and external surface consistent with cold working process, tube inner surface should be free from rust, scratches and other surface

irregularities.

The honing pipe is used for the hydraulic cylinder making.

Used as the pipes on the heated side of low and medium pressure boilers(normally with operating pressure not higher than 5.88Mpa and

operating temperature below 450 oc);as the pipes on the heated sides of high·pressure boilers,economizers,overheaters,reheaters and pipes

for petrochemical industry(with the operating pressure above 9.8Mpa and operating temperature ranging between 450~C~650~C

Specifications of major steel material:

Processing form | I.D.mm | Length | Straightness | I.D.tolerance | I.D.Roughness(RA) |

Cold-rolled | 30-100 | ≤12M | 0.3-1.0/1000 | H8-H10 | 0.4-1.6um |

Cold-drawn | 30-250 | ≤12M | H8-H10 | 0.8-1.6um | |

Hone | 40-500 | ≤12M | H8-H9 | 0.4-0.8um | |

SRB | 50-250 | ≤9M | H8 | 0.1-0.4um |

Tolerance of ID and WT

Size of inside Diameter(mm) | ID Tolerance | Tolerance of wall thickness | ||

30 | +0.0330 | +0.0520 | +0.0840 | <120mm(OD) ±5% >120mm up to 210mm±7.5% >210mm ±10% |

>30-50 | +0.0390 | +0.0620 | +0.1000 | |

>50-80 | +0.0460 | +0.0740 | +0.1200 | |

>80-120 | +0.0540 | +0.0870 | +0.1400 | |

>120-180 | +0.0630 | +0.1000 | +0.1600 | |

>180-250 | +0.0720 | +0.1150 | +0.1850 | |

>250-315 | +0.0810 | +0.1300 | +0.2100 | |

>315-400 | +0.0890 | +0.1400 | +0.2300 | |

Length and cut tolerance

Length ≤ 500mm , +2mm

> 500mm ≤ 2000mm, +3mm

> 2000mm ≤ 5000mm, +5mm

> 2000mm ≤ 7000mm, +10mm

Standard:DIN 2391,EN10305

Material: St45,St52,E355

Chemical composition

Steel grade | Chemical composition,% | |||||

C | Si | Mn | P | S | Cr | |

≤ | ||||||

St45 | 0.17-0.24 | 0.17-0.37 | 0.35-0.65 | 0.035 | 0.035 | 0.250 |

ST52(E355) | ≤0.22 | ≤0.55 | ≤1.6 | 0.025 | 0.025 | 0.25 |

SAE1026 | 0.22-0.28 | 0.15-0.35 | 0.60-0.90 | 0.040 | 0.050 | / |

27SiMn | 0.24-0.32 | 1.10-1.40 | 1.10-1.40 | 0.035 | 0.035 | 0.300 |

20# | 0.17-0.24 | 0.17-0.37 | 0.35-0.65 | 0.035 | 0.035 | 0.250 |

9. Mechanical Properties

Delivery condition | BK Cold finished(hard) | BKS Cold drawn and stress-relieved | |||

Steel grade | Rm Mpa | Elongation A5(%) | Rm MPa | ReH MPa | Elonggation A5(%) |

ST45 | ≥550 | ≥5 | ≥520 | ≥375 | ≥15 |

ST52(E355) | ≥640 | ≥5 | ≥600 | ≥520 | ≥14 |

SAE1026 | ≥640 | ≥5 | ≥600 | ≥510 | ≥15 |

16Mn | ≥640 | ≥5 | ≥600 | ≥520 | ≥14 |

20# | ≥550 | ≥8 | ≥520 | ≥375 | ≥15 |

Tube ends

Tube ends shall be cut nominally square to the axis and free from burs

11.Delivery condition:BKS

Appearance

Tube shall have a smooth internal and external surface consistent with cold working process, tube inner surface should be free from rust, scratches and other surface

irregularities.