- Overview

- Product Description

- Detailed Photos

- Product photos

- Packaging & Shipping

- customers

- Our Advantages

- FAQ

Basic Info.

Product Description

15CrMoG High Pressure Seamless Boiler Tubes is GB 5310-95 steel grade (equivalent to 13CrMo44 of Federal Germany; corresponding to 1Cr-1 / 2Mo and 1 1 / 4cr-1 / 2mo-si steel widely used in various countries in the world)

15CrMoG Alloy steel pipe is a seamless steel tube, its performance is much higher than the general seamless steel pipe, because the inside of this tube contains CR more, its alloy steel tube high temperature, low-temperature, corrosion resistance of other seamless steel tubes, so the alloy tube in the petroleum, chemical, electric power, boiler and other industries are more widely used.

The range of 15CrMoG pipe sizes that may be examined by each method shall be subjected to the limitations in the scope of the respective practice.

For high-pressure boiler (working pressure 9.8MPa or more generally, the working temperature between 450ºC-650ºC) of heating surface tubes, header, economizer, superheater, reheater and so on.

Standard:GB 5310

Seamless steel tubes and pipes for high pressure boiler

GB 5310 standard is applicable to steam boilers and pipeline seamless pipes for the manufacture of high pressure and above.

15CrMoG is GB 5310-95 steel grade (equivalent to 13CrMo44 of Federal Germany; corresponding to 1Cr-1 / 2Mo and 1 1 / 4cr-1 / 2mo-si steel widely used in various countries in the world). Its chromium content is higher than 12CrMo steel, so it has higher thermal strength at 500-550 ºC. When the temperature is higher than 550 ºC, the thermal strength of 15CrMoG steel is significantly reduced. When it runs at 500-550ec for a long time, it does not produce graphitization, but it will produce carbide spheroidization and redistribution of alloy elements, which all lead to the decrease of the thermal strength of steel. 15CrMoG steel has good relaxation resistance at 450 ºC. Its pipe making and welding process performance is good.

(1)Steel smelting method

GB 5310 15CrMoG steel will be smelted by electric furnace plus furnace refining, oxygen converter plus furnace refining or electroslag remelting method.

(2)Manufacturing methods and requirements for tube blanks

The tube blank can be produced by continuous casting, die casting or hot rolling (forging).

(3)Manufacturing method of steel tube

GB 5310 15CrMoG Steel tubes shall be manufactured by hot rolling (extrusion, expansion) or cold drawing (rolling).

Heat treatment for GB 5310 15CrMoG High Pressure Boiler Tubes

| Grade | Heat treatment |

| 15CrMoG | 900 ºC~960 ºC,Normalizing;660 ºC~730 ºC,Tempering |

Chemical composition of GB 5310 15CrMoG

| Steel Pipe | Chemical Composition(%) | ||||||||

| C | Si | Mn | Cr | Mo | Ni | Cu | P | S | |

| Max | |||||||||

| 15CrMoG | 0.12~0.18 | 0.17~0.37 | 0.40~0.70 | 0.80~1.10 | 0.40~0.55 | ≤0.30 | ≤0.20 | 0.025 | 0.020 |

Mechanical properties of GB 5310 15CrMoG

| Tensile properties | Impact energy(Akv),J | Hardness | |||||||

| Tensile strength (MPa) | Yield Strength (MPa) | Elongation % | Portrait | Landscape | A | B | C | ||

| HBW | HV | HRC | |||||||

| Portrait | Landscape | ||||||||

| Max | Min | ||||||||

| 440~640 | 235 | 21 | 19 | 40 | 27 | 170 | 180 | 88HRB | |

Allowable deviation of outer diameter and wall thickness

| Type of steel pipe | Outer diameter(mm) | Tolerance | |||

| ordinary | advanced | ||||

| Hot rolled tube | OD | ≤50 | ±0.40 | ±0.30 | |

| >50~≤325 | WT≤35 | ±0.75% | ±0.5% | ||

| WT>35 | ±1% | ±0.75% | |||

| >325 | ±1% | ±0.75% | |||

| WT | ≤4.0 | ±0.4 | ±0.3 | ||

| >4.0~≤20 | ±10% | ±7.5% | |||

| >20 | OD<219 | ±10% | ±7.5% | ||

| OD≥219 | +12.5% -10% | ±10% | |||

| Cold drawn tube | OD | ≤25.4 | ±0.15 | - |

| >25.4~≤40 | ±0.20 | - | ||

| >40~≤50 | ±0.25 | - | ||

| >50~≤60 | ±0.30 | - | ||

| >60 | ±0.5% | - | ||

| WT | ≤2.8 | ±0.2 | - | |

| >2.8 | ±7.5% | - |

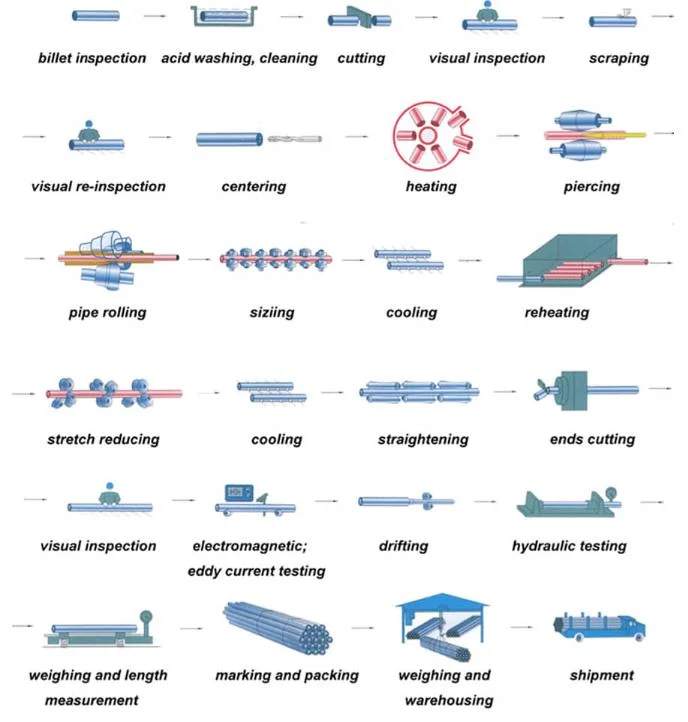

Hot rolling process mainly includes the following steps:

Materials: Take raw materials out of the raw material warehouse or procurement channels, and conduct inspection and sorting; Temperature control: according to the required performance of the product, choose the appropriate temperature, and control it in a certain range; Heating: Use hot blast stove or other heating methods to heat raw materials to the required temperature; Annealing: Put the heated raw materials into the torch box for annealing treatment to improve the mechanical properties of raw materials;

Hot rolling: Put the heated raw material into the hot rolling mill, and process the raw material through pressure to obtain the required product; Cooling: the product after hot rolling is cooled with water or other coolant to ensure the stability of the product structure; Detection: physical and chemical performance inspection to determine whether it meets the requirements; Finishing: The product is sorted out, then labeled, ready for loading and shipping.

(1)Hydraulic test

The steel pipe shall be hydraulically tested one by one, and the eddy current testing can instead of the hydraulic test.

(2)Flattening test

Steel pipes with an outer diameter greater than 22 mm to 400 mm and a wall thickness not greater than 40 mm shall be subjected to a flattening test.

(3)Bending test

Steel pipes with an outer diameter greater than 400 mm or a wall

(4)Flaring test

The steel pipe with an outer diameter of not more than 76 mm and a wall thickness of not more than 8 mm can be used for the flare test.

(5)Low-power test

Steel pipes should be tested at low magnification. Visually visible white spots, inclusions, subcutaneous bubbles, tumbling and delamination are not allowed on the cross-section acid immersion test piece.

(6) Non-metallic inclusions

Steel pipes shall be tested for non-metallic inclusions.

(7)grain size

The finished steel pipe should be tested for grain size.

(8)Microstructure

The finished steel pipe with the grades 15CrMoG will be ferrite plus pearlite, allowing the presence of granular bainite, and no phase change critical temperature between AC1 and AC3 is allowed.

(9)Decarburization layer

Cold drawn (rolled) finished steel pipes with an outer diameter of not more than 76 mm shall be inspected for the total decarburization layer.

(10)Non-destructive testing

The steel pipe shall be ultrasonically inspected and tested in accordance with the provisions of GB/T 5777.

Surface quality

The inner and outer surfaces of steel pipes do not have cracks, folds, crusting, rolling and separation. These defects shall be completely removed and the depth of defect removal shall not exceed 10% of the wall thickness. The actual outer diameter and wall thickness of the defect removal shall not be less than the minimum allowable for the outer diameter and wall thickness.

GB 5310 15CrMoG Seamless steel tubes and pipes for high pressure boiler

Our company was established in 2012, is a comprehensive company integrating industry and trade. The company has successively won the honorary titles of provincial integrity enterprise and municipal excellent enterprise. We are mainly engaged in various metal related products. Such as pipes, pipe fittings, rods, coils, profiles, medium and heavy plates, narrow strips and other types of materials. The warehouse has a variety of products of different specifications and materials, and the capacity is maintained at 30,000-50,000 tons/month. Products are widely used in petroleum, chemical, electric power, coal, machinery, high and low pressure boiler tubes, hydraulic props, ships and other industries. We make full use of the advantages of self-operated export rights and enter the international market. Our customers are located in South Korea, Canada, Iran, Pakistan, Indonesia, Vietnam, South America and other countries, and we have offices in Indonesia and Vietnam. The quality of our products is enjoyed at home and abroad. high reputation. We adhere to the business philosophy of "integrity service, win-win cooperation, customer first", and provide one-stop steel solutions for global customers. Welcome friends from all over the world to visit our company. We are looking forward to establishing business relationships and personal friendships with you.

Why choose us?

Q:How do you control quality?

A:Mill test certification is supplied with shipment,third party inspection is avaliable.

Q:What are the advantages of your company?

A:We have many professionals,technical personnel,more competitive prices and best after-sales service than other stainless steel companies.

Q:How many coutries you already exported?

A:Exported to more than 50 countries mainly from Arab, Kuwait, Egypt, Turkey, Jordan, Brazil, India, Indonesia, Korea, etc.

Q:Can you provide sample?

A:Small sample in store and can provide the sample for free.Customized samples will take about 5-7days

Q:Why should you buy from us not from other suppliers?

A:Diversified products, direct supply from manufacturer.

Q:What is your terms of payment ? A:we accept T/T ,L/C ,D/A,D/P, Western union, paypal ,The payment method can be negotiated by both parties according to the actual situation.

Please Please leave your enquiry in the message box at the bottom of the product page and click SEND, we will contact you as soon as possible !