- Overview

- Product Parameters

- Detailed Photos

- Company Profile

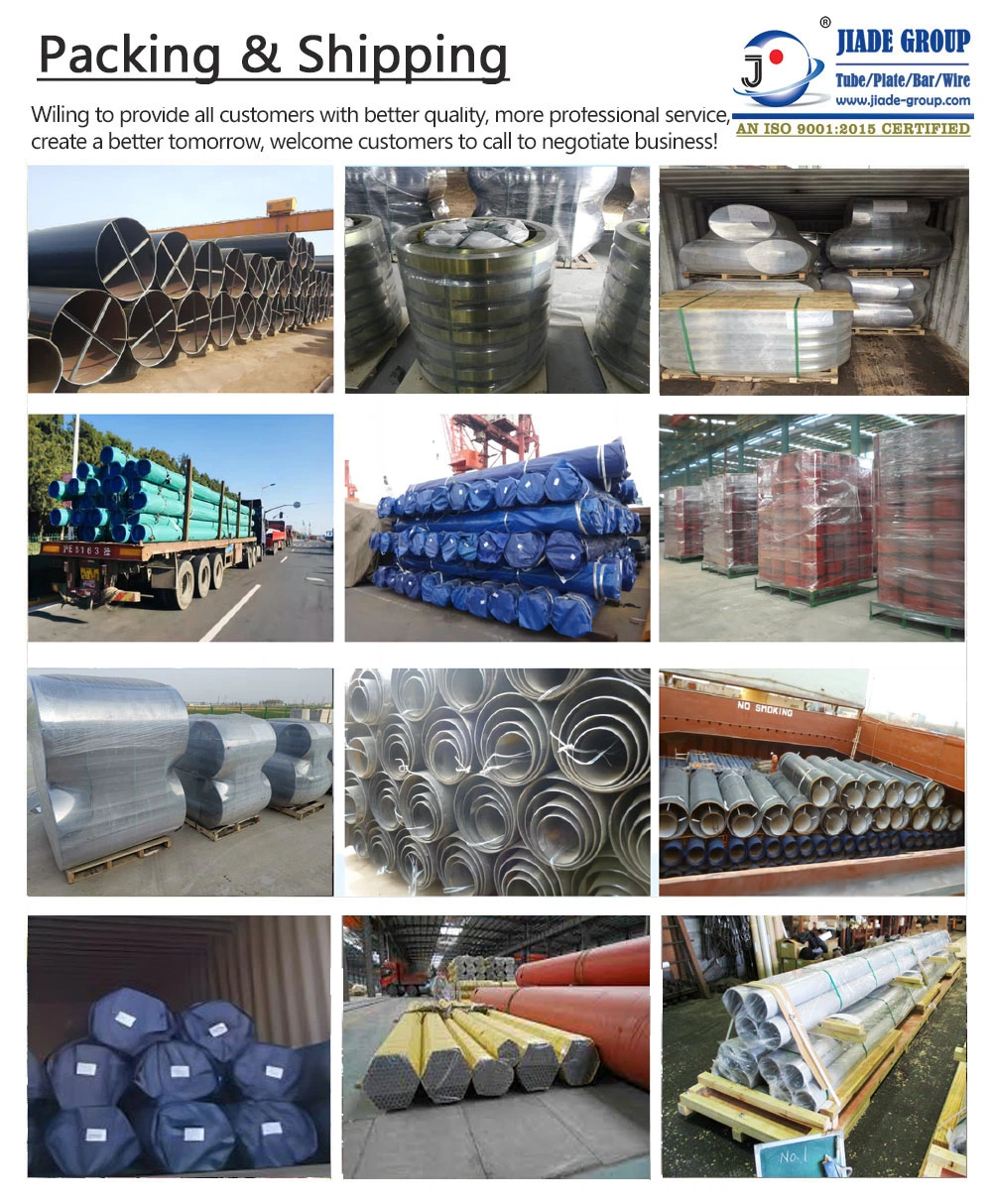

- Packaging & Shipping

- Certifications

- Main Export Markets

Basic Info.

Model NO.

4130

Special Use

High-strength Steel Plate, Wear Resistant Steel, Cold Heading Steel, Mold Steel

Application

Structural Steel Bar

Materials

10#-45#,20mng,25mng,15crmog,35CrMo,16mn,etc

Outer Diameter

21-1030mm

Length

5.8m-12m or as Required

Thickness

6 - 60 mm

Steel Grade

4130 4140

Transport Package

in Bundles or Wooden Box

Specification

21.3-1219mm

Trademark

JIADE

Origin

China

HS Code

7307930000

Production Capacity

5000tons

Product Description

| Model Number | 4130 Chromium-Molybdenum Alloy Tube | ||||

|---|---|---|---|---|---|

| Brand Name | JIADE STEEL PIPE | ||||

| origin | China | ||||

| Small Orders | Accepted | ||||

Key Specifications/ Special Features:

The Chinese grade of 4130 chromium molybdenum steel is 30CrMo.So 30 is carbon.J857Cr electrode can be used for welding.For industrial pressure pipe, chromium molybdenum steel welding materials, according to the steel Cr, Mo content can choose different electrode, wire.

If steel number: 12CrMo(0.5 cr-0.5 Mo), can choose R207 electrode.Wire TIG - R30

15CrMo(1cr-0.5 Mo), choose R307 electrode, wire tig-r30

12CrMoV(1 cr-0.5 mo-v), choose R317 electrode.Wire TIG - 31

12Cr2Mo(2.5 cr-0.5 Mo), choose R407 electrode, wire tig-40

1Cr5Mo(5cr-0.5 Mo), choose R507 electrode, wire tig-40

Cr9Mo(9cr-1mo), choose R707 electrode, wire tig-40 can be.

Ordinary seamless tube material: 10#, 20#, 35#, 45#, 16Mn(Q345B\Q345C\Q345D\Q345E)

Seamless alloy material: GCr15, 27SiMn, 15CrMoG, 12Cr1MoVG, 35CrMo, 42CrMo, Cr5Mo, Cr9Mo, A335P11, A335P22, A335P91, 10CrMo910.

If steel number: 12CrMo(0.5 cr-0.5 Mo), can choose R207 electrode.Wire TIG - R30

15CrMo(1cr-0.5 Mo), choose R307 electrode, wire tig-r30

12CrMoV(1 cr-0.5 mo-v), choose R317 electrode.Wire TIG - 31

12Cr2Mo(2.5 cr-0.5 Mo), choose R407 electrode, wire tig-40

1Cr5Mo(5cr-0.5 Mo), choose R507 electrode, wire tig-40

Cr9Mo(9cr-1mo), choose R707 electrode, wire tig-40 can be.

Ordinary seamless tube material: 10#, 20#, 35#, 45#, 16Mn(Q345B\Q345C\Q345D\Q345E)

Seamless alloy material: GCr15, 27SiMn, 15CrMoG, 12Cr1MoVG, 35CrMo, 42CrMo, Cr5Mo, Cr9Mo, A335P11, A335P22, A335P91, 10CrMo910.

Tests we apply to the tubes:

1. Chemical composition analysis

2. Mechanical properties (tensile strength, yield strength, elongation, hardness)

3. Technological test (flattening test, flaring test, bending test, hydraulic pressure test)

4. Surface quality detection

5. Eddy-current examination

6. Visual test

Applications:

1. Architectural/civil engineering: cladding, handrails, door and window fittings, street furniture, structural sections, enforcement bar, lighting columns, lintels, masonry supports.

2. Transport: exhaust systems, car trim/grilles, road tankers, ship containers, ships chemical tankers, refuse vehicles.

3. Chemical/pharmaceutical: pressure vessels, process piping.

4. Oil and gas: platform accommodation, cable trays, sub-sea pipelines.

5. Medical: surgical instruments, surgical implants, food processing

6. Food and drink: catering equipment, brewing, distilling, food processing.

7. Water: water and sewage treatment, water tubing, hot water tanks

8. General: springs, fasteners (bolts, nuts and washers) wire.

Packaging:

1. Bundle packing, wooden cases or as customer's request.

2. Beveled end or plain end or varnished as per buyer's required

3. Marking: as per customer's requests

Delivery lead time: with 15-30 days after full payment received

Our services: third party inspection accepted such as SGS, BV.

Lead time 10-15 days | 80% of output for export

Lead time 10-15 days | 80% of output for export

A Trading Company Specializing in Steel Industry for Over 30 Years

Shaanxi Jiade Import & Export is one of the leading professional steel pipes and pipe fitting suppliers, established in 1991 and charge of the export business. We have more than 30 years' experience in manufacturing, distributing, processing, and exporting hot rolled and cold drawn seamless, ERW, EFW, HFW, LSAW, DSAW, and SSAW pipes boiler tubes, heat-exchanger tubes, condenser tubes, super-heater tubes, hydraulic honed tubes, mechanical tubes, structural tubes, line pipes, elbows, tees, reducers, and flanges. We mainly export products to Africa, Asia, Europe, Oceania, and North and South America.

Supported by Machines and Equipment

All our products are manufactured with the latest manufacturing techniques with machines and equipment, which are fitted with the highest technology, to provide products in full conformity with international standards.

Meeting Inspection and Approval Certificates

We have passed the Mill Test certificate, C/W certificate (Calibration works certificate) EN 10204 3.1, DIN 50049 3.1, ISO 10474 3.1, NACE MR-0103/NACE MR-0175/ISO 15156, PED-97/23/EC, AD-2000-WO, with 3.2 certificates duly certified and approved by LRS, GL, BV, DNV, ABS, SGS, TUV, RINA, IRS, NORSOK and more.

Customized Service

We provide product customization services such as shot blasting, precision pipe cutting, cut and roll grooving, custom pipe fabrication, pipe threading, pipe beveling, and coating. They are also approved by Third Party inspection agencies like DNV, BV, SGS, Moody, TuV, ABS, LR, GL, PED, RINA, KR, NKK, AIB-VINEOTTE, CEIL, VELOSI, CCSI, and more. We supply for PetroVietnam, WSF, YPFB, AWH, HMC, PTT, EP PetroEcuador, POD, KNPC, and more.

Establishing Friendly Partnership

Our mission is whether our clients are active in the oil and gas, water supply line, or construction, we endeavor to deliver the highest quality products and value-added services to support our clients' business. We pursue a win-win situation and long-term cooperative relationships with customers, providing specializing service for the old and new customers with better and more economical results.

Shaanxi Jiade Import & Export is one of the leading professional steel pipes and pipe fitting suppliers, established in 1991 and charge of the export business. We have more than 30 years' experience in manufacturing, distributing, processing, and exporting hot rolled and cold drawn seamless, ERW, EFW, HFW, LSAW, DSAW, and SSAW pipes boiler tubes, heat-exchanger tubes, condenser tubes, super-heater tubes, hydraulic honed tubes, mechanical tubes, structural tubes, line pipes, elbows, tees, reducers, and flanges. We mainly export products to Africa, Asia, Europe, Oceania, and North and South America.

Supported by Machines and Equipment

All our products are manufactured with the latest manufacturing techniques with machines and equipment, which are fitted with the highest technology, to provide products in full conformity with international standards.

Meeting Inspection and Approval Certificates

We have passed the Mill Test certificate, C/W certificate (Calibration works certificate) EN 10204 3.1, DIN 50049 3.1, ISO 10474 3.1, NACE MR-0103/NACE MR-0175/ISO 15156, PED-97/23/EC, AD-2000-WO, with 3.2 certificates duly certified and approved by LRS, GL, BV, DNV, ABS, SGS, TUV, RINA, IRS, NORSOK and more.

Customized Service

We provide product customization services such as shot blasting, precision pipe cutting, cut and roll grooving, custom pipe fabrication, pipe threading, pipe beveling, and coating. They are also approved by Third Party inspection agencies like DNV, BV, SGS, Moody, TuV, ABS, LR, GL, PED, RINA, KR, NKK, AIB-VINEOTTE, CEIL, VELOSI, CCSI, and more. We supply for PetroVietnam, WSF, YPFB, AWH, HMC, PTT, EP PetroEcuador, POD, KNPC, and more.

Establishing Friendly Partnership

Our mission is whether our clients are active in the oil and gas, water supply line, or construction, we endeavor to deliver the highest quality products and value-added services to support our clients' business. We pursue a win-win situation and long-term cooperative relationships with customers, providing specializing service for the old and new customers with better and more economical results.

Shipping Information

Shipping Information

| FOB Port | Tianjin | ||||

|---|---|---|---|---|---|

| Weight per Unit | 1500.0 Kilograms | ||||

| HTS Code | 7304.41.90 00 | ||||

| Export Carton Dimensions L/W/H | 11.8 x 1.0 x 0.8 Meters | ||||

| Lead Time | 15-30 days | ||||

|---|---|---|---|---|---|

| Dimensions per Unit | 11.8 x 1.0 x 0.8 Meters | ||||

| Units per Export Carton | 25.0 | ||||

| Export Carton Weight | 1500.0 Kilograms | ||||

- Asia

- Australasia

- Central/South America

- Eastern Europe

- Mid East/Africa

- North America

- Western Europe

- <li>Southeast Asia

Lead time 10-15 days | 80% of output for export

Lead time 10-15 days | 80% of output for export