- Overview

- Product Description

- Product Parameters

- Detailed Photos

- Packaging & Shipping

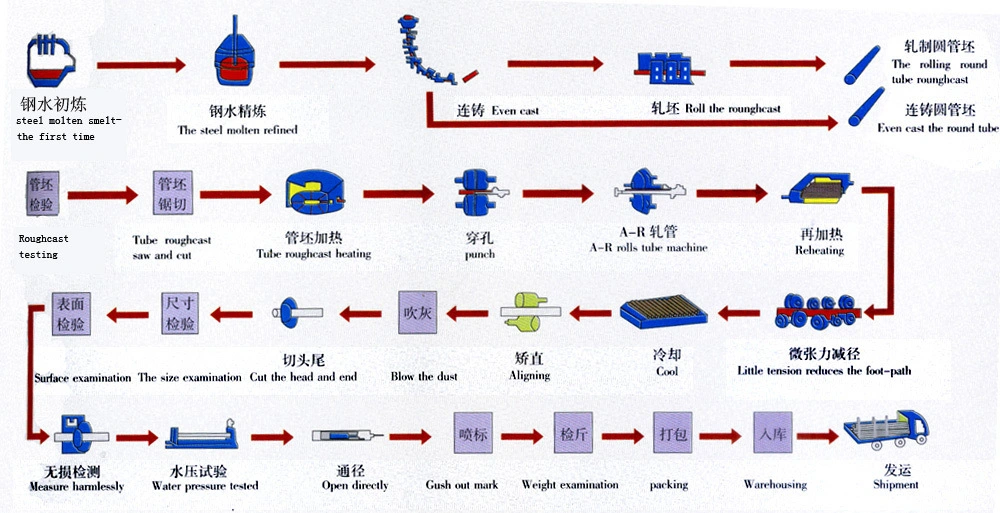

- Production process

- Certifications

- Company Profile

- Contact Us

Basic Info.

Product Description

The production process of general seamless steel pipes can be divided into two types: cold-drawn and hot-rolled. The production process of cold-rolled seamless steel pipes is generally more complicated than that of hot rolling. In the sizing test, if the surface does not respond to cracks, the pipe must be cut by a cutting machine and cut into a blank of about one meter in length. Then enter the annealing process. Annealing needs to be pickled with acid liquid. When pickling, pay attention to whether there is a large amount of blistering on the surface. If there is a large amount of blistering, it means that the quality of the steel pipe does not meet the corresponding standards.

1.ASTM A53

Specification for Seamless and Welded Black and Hot-Dipped Galvanized Steel Pipe

| Composition, max, % | |||||

| Elt | C | Mn | P | S | |

| Type S (seamless pipe) | |||||

| Gr. A | 0.25 | 0.95 | 0.05 | 0.045 | |

| Gr. B | 0.3 | 1.2 | 0.05 | 0.045 | |

| Type E (electric-resistance-welded) | |||||

| Gr. A | 0.25 | 0.95 | 0.05 | 0.045 | |

| Gr. B | 0.3 | 1.2 | 0.05 | 0.045 | |

| Type F (furnace-welded pipe) | |||||

| Gr. A | 0.3 | 1.2 | 0.05 | 0.045 | |

| Composition, max, % | |||||

| Elt | Cu (1) | Ni (1) | Cr (1) | Mo (1) | V (1) |

| Type S (seamless pipe) | |||||

| Gr. A | 0.4 | 0.4 | 0.4 | 0.15 | 0.08 |

| Gr. B | 0.4 | 0.4 | 0.4 | 0.15 | 0.08 |

| Type E (electric-resistance-welded) | |||||

| Gr. A | 0.4 | 0.4 | 0.4 | 0.15 | 0.08 |

| Gr. B | 0.4 | 0.4 | 0.4 | 0.15 | 0.08 |

| Type F (furnace-welded pipe) | |||||

| Gr. A | 0.4 | 0.4 | 0.4 | 0.15 | 0.08 |

2.ASTM A105

Specification for Carbon Steel Forgings for Piping Applications

| Composition, % | |||||

| Elt | C | Mn | P | S | Si |

| 0.35 | 0.6 | 0.035 | 0.04 | 0.1 | |

| max | 1.05 | max | max | 0.35 | |

| Composition, % | |||||

| Elt | Cu | Ni | Cr | Mo | V |

| 0.4 | 0.4 | 0.3 | 0.12 | 0.08 | |

| max (1) | max (1) | max (1-2) | max (1-2) | max | |

3.ASTM A106

Specification for Seamless Carbon Steel Pipe for High-Temperature Service

| Composition, % | |||||

| Elt | C | Mn | P | S | Si |

| max | max | max | min | ||

| Gr. A | 0.25 (1) | 0.27 | 0.035 | 0.035 | 0.1 |

| 0.93 | |||||

| Gr. B | 0.30 (2) | 0.29 | 0.035 | 0.035 | 0.1 |

| 1.06 | |||||

| Gr. C | 0.35 (2) | 0.29 | 0.035 | 0.035 | 0.1 |

| 1.06 | |||||

| Composition, % | |||||

| Elt | Cr | Cu | Mo | Ni | V |

| max (3) | max (3) | max (3) | max (3) | max (3) | |

| Gr. A | 0.4 | 0.4 | 0.15 | 0.4 | 0.08 |

| Gr. B | 0.4 | 0.4 | 0.15 | 0.4 | 0.08 |

| Gr. C | 0.4 | 0.4 | 0.15 | 0.4 | 0.08 |

4.ASTM A216

Specification for Steel Castings, Carbon, Suitable for Fusion Welding, for High-Temperature Service

| Composition, % max | |||||

| Gr. | C | Mn | P | S | Si |

| WCA | 0.25 (1) | 0.70 (1) | 0.04 | 0.045 | 0.6 |

| UNS J02502 | |||||

| WCB | 0.30 (2) | 1.00 (2) | 0.04 | 0.045 | 0.6 |

| UNS J03002 | |||||

| WCC | 0.25 (3) | 1.20 (3) | 0.04 | 0.045 | 0.6 |

| UNS J02503 | |||||

| Composition, % max | |||||

| Gr. | C | Mn | P | S | Si |

| WCA | 0.25 (1) | 0.70 (1) | 0.04 | 0.045 | 0.6 |

| UNS J02502 | |||||

| WCB | 0.30 (2) | 1.00 (2) | 0.04 | 0.045 | 0.6 |

| UNS J03002 | |||||

| WCC | 0.25 (3) | 1.20 (3) | 0.04 | 0.045 | 0.6 |

| UNS J02503 | |||||

5.ASTM A234

Specification for Piping Fittings of Wrought Carbon Steel and Alloy Steel for Moderate and High Temperature Service

| Composition, % | |||||

| Gr. | C | Mn | P | S | Si |

| max | max | ||||

| WPB | 0.3 | 0.29 | 0.05 | 0.058 | 0.1 |

| (1 2 3 4 5) | max | 1.06 | min | ||

| WPC | 0.35 | 0.29 | 0.05 | 0.058 | 0.1 |

| (2 3 4 5) | max | 1.06 | min | ||

| WP1 | 0.28 | 0.3 | 0.045 | 0.045 | 0.1 |

| max | 0.9 | 0.5 | |||

| WP12 CL1 | 0.05 | 0.3 | 0.045 | 0.045 | 0.6 |

| 0.2 | 0.8 | max | |||

| WP12 CL2 | 0.05 | 0.3 | 0.045 | 0.045 | 0.6 |

| 0.2 | 0.8 | max | |||

| WP11 CL1 | 0.05 | 0.3 | 0.03 | 0.03 | 0.5 |

| 0.15 | 0.6 | 1 | |||

| WP11 CL2 | 0.05 | 0.3 | 0.04 | 0.04 | 0.5 |

| 0.2 | 0.8 | 1 | |||

| WP11 CL3 | 0.05 | 0.3 | 0.04 | 0.04 | 0.5 |

| 0.2 | 0.8 | 1 | |||

| WP22 CL1 | 0.05 | 0.3 | 0.04 | 0.04 | 0.5 |

| 0.15 | 0.6 | max | |||

| WP22 CL3 | 0.05 | 0.3 | 0.04 | 0.04 | 0.5 |

| 0.15 | 0.6 | max | |||

| WP5 CL1 | 0.15 | 0.3 | 0.04 | 0.03 | 0.5 |

| max | 0.6 | max | |||

| WP5 CL3 | 0.15 | 0.3 | 0.04 | 0.03 | 0.5 |

| max | 0.6 | max | |||

| WP9 CL1 | 0.15 | 0.3 | 0.03 | 0.03 | 1 |

| max | 0.6 | max | |||

| WP9 CL3 | 0.15 | 0.3 | 0.03 | 0.03 | 1 |

| max | 0.6 | max | |||

| WPR | 0.2 | 0.4 | 0.045 | 0.05 | |

| max | 1.06 | ||||

| WP91 | 0.08 | 0.3 | 0.02 | 0.01 | 0.2 |

| 0.12 | 0.6 | 0.5 | |||

| WP911 | 0.09 | 0.3 | 0.02 | 0.01 | 0.1 |

| 0.13 | 0.6 | 0.5 | |||

| Composition, % | |||||

| Gr. | Cr | Mo | Ni | Cu | Others |

| WPB | 0.4 | 0.15 | 0.4 | 0.4 | V 0.08 |

| (1 2 3 4 5) | max | max | max | max | max |

| WPC | 0.4 | 0.15 | 0.4 | 0.4 | V 0.08 |

| (2 3 4 5) | max | max | max | max | max |

| WP1 | 0.44 | ||||

| 0.65 | |||||

| WP12 CL1 | 0.8 | 0.44 | |||

| 1.25 | 0.65 | ||||

| WP12 CL2 | 0.8 | 0.44 | |||

| 1.25 | 0.65 | ||||

| WP11 CL1 | 1 | 0.44 | |||

| 1.5 | 0.65 | ||||

| WP11 CL2 | 1 | 0.44 | |||

| 1.5 | 0.65 | ||||

| WP11 CL3 | 1 | 0.44 | |||

| 1.5 | 0.65 | ||||

| WP22 CL1 | 1.9 | 0.87 | |||

| 2.6 | 1.13 | ||||

| WP22 CL3 | 1.9 | 0.87 | |||

| 2.6 | 1.13 | ||||

| WP5 CL1 | 4 | 0.44 | |||

| 6 | 0.65 | ||||

| WP5 CL3 | 4 | 0.44 | |||

| 6 | 0.65 | ||||

| WP9 CL1 | 8 | 0.9 | |||

| 10 | 1.1 | ||||

| WP9 CL3 | 8 | 0.9 | |||

| 10 | 1.1 | ||||

| WPR | 1.6 | 0.75 | |||

| 2.24 | 1.25 | ||||

WP91 | 8 | 0.85 | 0.4 | V 0.18 | |

| 9.5 | 1.05 | max | 0.25 | ||

| Nb 0.06 | |||||

| 0.1 | |||||

| N 0.03 | |||||

| 0.07 | |||||

| Al 0.02 max (6) | |||||

| Ti 0.01 max (6) | |||||

| Zr 0.01 max (6) | |||||

WP911 | 8 | 0.9 | 0.4 | V 0.18 | |

| 9.5 | 1.1 | max | 0.25 | ||

| Nb 0.06 | |||||

| 0.1 | |||||

| N 0.04 | |||||

| 0.09 | |||||

| Al 0.02 max (6) | |||||

| B 0.0003 | |||||

| 0.006 | |||||

| W 0.9 | |||||

| 1.1 | |||||

| Ti 0.01 max (6) | |||||

| Zr 0.01 max (6) | |||||

Shandong Xinchengyuan Import and Export Co., Ltd is a professional steel company engaged in the research, development, production, sale and service. It had five branch companies .Our annual sales nearly one billion, about 280,000 tons steel, It is located in Jinan with the convenient transportation access. In line with the development concept of quality conquer the world, service achievement future.

Please contact us

Ivy Zhang