- Overview

- Our Advantages

- Product Parameters

- Company Profile

- Product Description

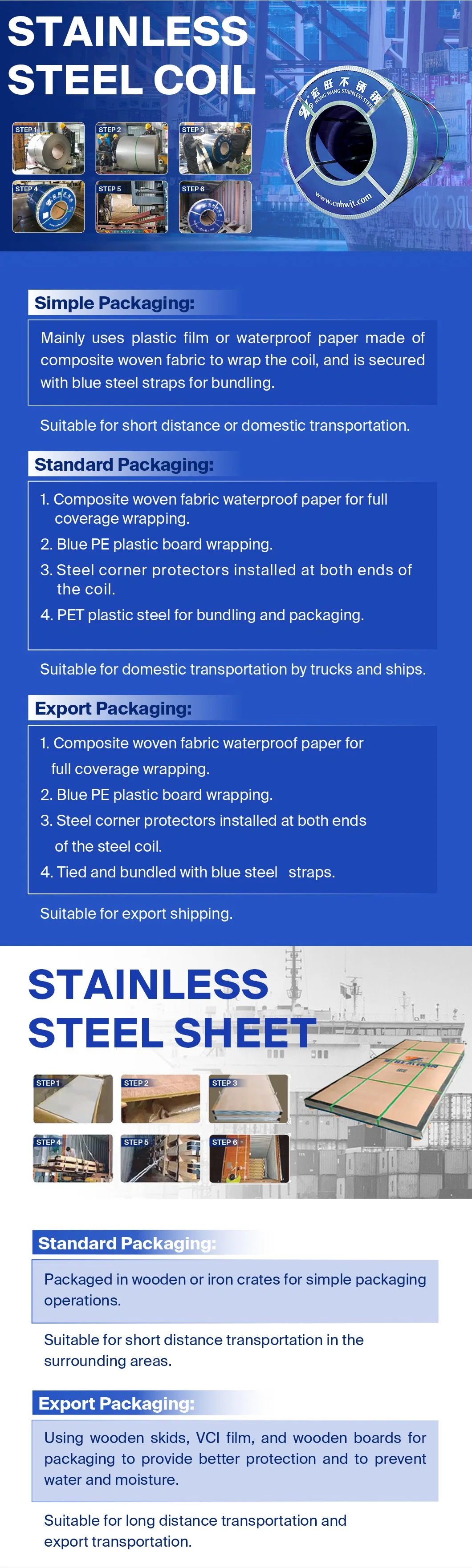

- Packaging & Shipping

- Certifications

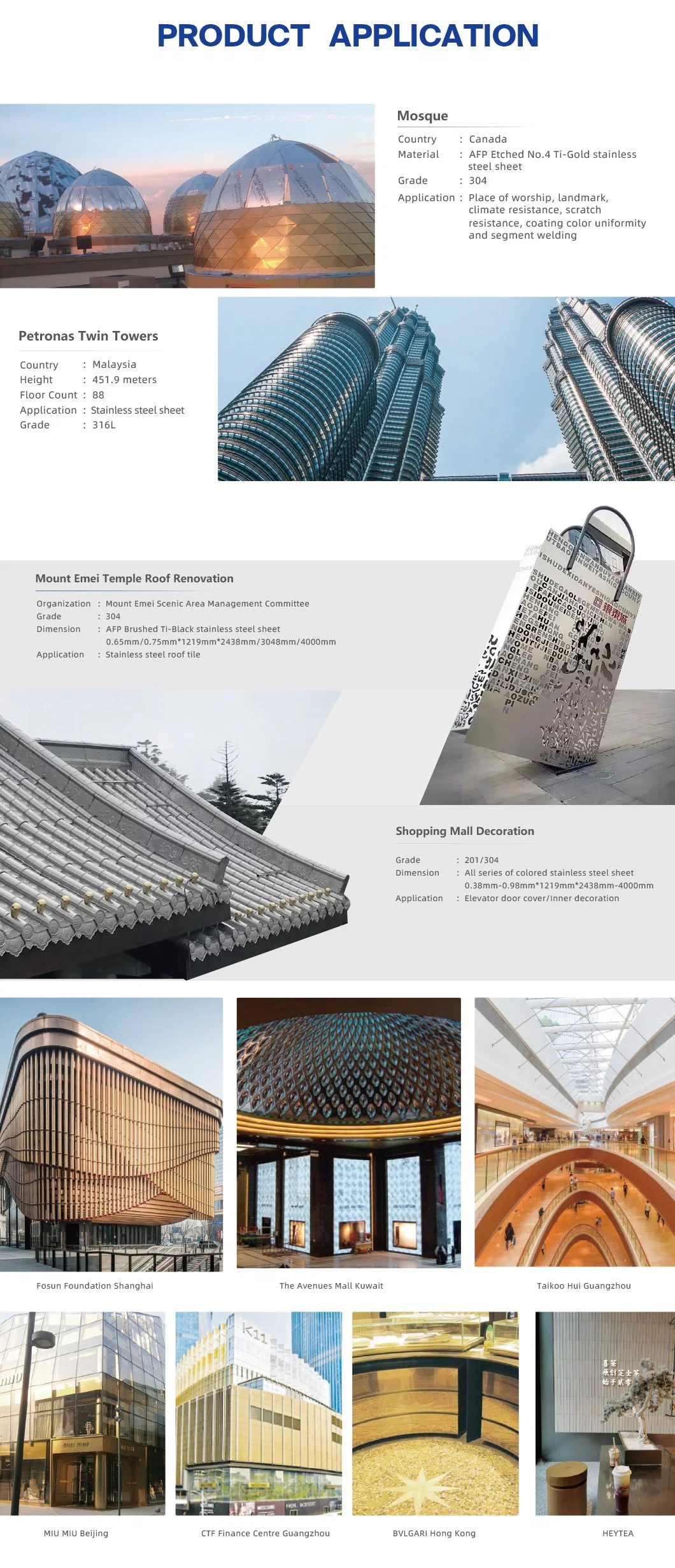

- Application

- FAQ

Basic Info.

Product Description

1. Seven production bases in China, equipping with strict quality inspection and comprehensive after-sales service and offerring professional solutions in time;

2. The world's first breakthrough in stainless steel five-foot wide five-continuous rolling technology;

3. The first stainless steel whole-roll water plating black titanium and whole-roll vacuum plating color coil;

4. Annual output value of up to 10 million tons, can meet the product customization of more than 60 countries;

5. Grade: 200 Series / 300 Series / 400 Series;

6. Standard: QB / GB / ASTM / JIS / EN / BIS

Stainless steel seamless pipe is a long strip of steel with a hollow section and no seams around it. The thicker the wall thickness of the product, the more economical and practical it is, and the thinner the wall thickness, the higher its processing cost will be.

The process of this product determines its limited performance. Generally, seamless steel pipes have low precision: Uneven wall thickness, low brightness inside and outside the tube, high cost of cutting to length, and pits and black spots on the inside and outside are not easy to remove; its detection and shaping must be handled offline. Therefore, it embodies its superiority in terms of high pressure, high strength, and mechanical structural materials

| Material | 201, 202 301, 304, 304L, 316, 316L, 316Ti, 309, 310, 317, 321 409, 410, 420, 430, 436, 444, 441, 440C 904L, 2205, 2507 ,2101, 2520, 2304 |

| Grade | 200 Series / 300 Series / 400 Series |

| Standard | QB / GB / ASTM / JIS / EN |

| Diameter | 1mm - 4500mm |

| Specifications | Customization |

| Thickness | 0.2mm - 100mm, Customization |

| Application | Pipeline Transport, Boiler Pipe, Hydraulic, Automobile Pipe, Machinery Industry, Chemical Industry, Mining, etc. |

| Surface | BA, 2B, No. 1, No. 4, 8K, HL, 2D, etc. |

| Transport Package | Standard Export Packing / Customized |

| Date of Delivery | 15 - 45 days |

| Payment Term | LC, T/T, D/P, PayPal, Western Union, etc. |

| Price Term | FOB, EXW, CFR, CIF, etc. |

| MOQ | 1 Tons |

| Sample | Free Sample |

| Capacity | 10 Million Tons / Year |

| Item | Surface Finishing | Surface Finishing Methods | Application |

| NO. 1 | HR | heat treatment after hot rolling, pickling, or with treatment | for without the purpose of the surface gloss |

| 2B | After SPM | giving No. 2 processing materials appropriate method of cold light sheen | general materials, building materials, (most of the goods are processed) |

| BA | Bright annealed | bright heat treatment after cold rolling, in order to be more shiny, cold light effect | automotive parts, home appliances, vehicles, medical equipment, food equipment |

| HL (Hair Lines) | Polishing line having a long continuous processing | in a suitable size (usually mostly No. 150-240 grit) abrasive tape for as long as the hair, having a continuous processing method of polishing line | the most common building materials processing |

| 2D | Without the SPM | method of heat treatment after cold rolling, pickling surface roller with wool or eventually a light rolling a matte surface processing | general materials, building materials |

| NO. 3 | Shiny coarse grain processing | the No. 2D or No. 2B processing timber No. 100-120 polishing abrasive grinding belt | building materials, kitchen supplies |

| NO. 4 | After CPL | the No. 2D or No. 2B processing timber No. 150-180 polishing abrasive grinding belt | building materials, kitchen supplies, vehicles, medical equipment, food equipment |

| 240# | Grinding of fine lines | the No. 2D or No. 2B processing timber 240 polishing abrasive grinding belt | kitchen appliances |

| 320# | More than 240 lines of grinding | the No. 2D or No. 2B processing timber 320 polishing abrasive grinding belt | kitchen appliances |

| 400# | Close to BA luster | the No. 2B timber 400 polishing wheel polishing method | building materials, kitchen utensils |

| NO. 6 | No. 4 processing less than the reflection, the extinction | No. 4 processing material used for polishing tampico brushing | building materials, decorative |

| NO. 7 | Highly accurate reflectance mirror processing | No. 600 of the rotary buff with a polishing | building materials, decorative |

| NO. 8 | Highest reflectivity mirror finish | fine particles of abrasive material in order polishing, mirror polishing with a polishing | building materials, decorative, mirrors |

Q: How can I get some samples?

A: Catalogue and most sample pieces are already in stock.

Customized samples will take about 5-7days. Please contact us for further support.

Q: What is the MOQ?

A: If you are scheduling to place a small quantity order or trial order, feel free to contact us, we can meet your requirements.

Q: Can you OEM or ODM?

A: Yes, we have a strong developing team. The products can be made according to your request.

Q: How long Can You Guarantee for this product / finish?

A: Colors guarantee for more than 10 years. Original materials quality certificate can be provided.

Q: What kinds of payment methods do you accept?

A: We accept the payment by T/T or L/C, besides, you can transfer to our bank account, Western Union or PayPal.

Q: What is the average lead time?

A: For samples, the lead time is about 5-7 days.

For mass production, the lead time is 25-35 days. In all cases, we will try best to accommodate your needs.