Basic Info.

Product Description

Anti-corrosion steel pipe is processed through the reservation process, which can effectively prevent or slow sown the process in the transport and used of chemical or electrochemical corrosion reaction of steel pipe.

Anti-corrosion steel pipe is mainly used for petroleum,chemical, gas,heat, sewage treatment,water, bridges, steel pipes and other engineering fields.

Anti-corrosion steel pipe is divided into the following categories:

FBE epoxy powder corrosion

FBE epoxy powder anti-corrosion structure:electrostatic spraying the surface of the steel epoxy powder coating, a film. The coating has a coating operation is simple, clean, coating impact resistance and bending properties, temperature resistance advantage.

2PE/3PE corrosion

2PE/3PE corrosion structure: the surface of the steel and epoxy powder electrostatic spraying adhesive side wound,lateral wound polyethylene coating, combined with the excellent performance of the three, thus significantly improving the overall quality of pipeline corrosion.Resistant to chemical corrosion, resistance to cathodic disbondment resistance mechanical damage to properties.

Coal tar epoxy anti-corrosive

Coal tar epoxy anti-corrosive structure:from the epoxy resin + filler made of coal tar pitch + anti-corrosion coating on steel surface coated with glass cloth to strengthen the formation of coating, commonly used in the pipe wall corrosion.Thickness of 0.5-1.0mm.

High-density polyethylene jacket corrosion

High density polyethylene jacket corrosion structure:the outer surface of pipe wrapped in high-density polyethylene material, with a high mechanical strength and excellent corrosion resistance, can protect the steel in the transportation, installation and use of the process to avoid external factors the damage.

Double Flanged Ductile Cast Iron Pipe is the first choice of pipe for the municipal water supply project

with advantages of convenient installation, good seismic performance and corrosion resistance.

The range of sizes of our Ductile Iron pipes are from DN80mm to DN1800.

Double Flanged Ductile Iron Pipes are layed in the way of mechanical flanged joint in the project site.

| Product name | FBE/DUAL FBE/3LPE/3PE/2PE COATING steel pipe Fittings | |

| Steel Pipe Fitting | Material | WPB/WPC/A105/Q235/Q345/A106/X52N/20#/Gr.B etc. |

| Standard | GB/ASTM A/API 5L etc. | |

| Welding | WELD/SMLS | |

| products | elbow,tee,reducer,cross,cap,union etc. | |

| Diameter range | 21.3 - 1800mm | |

| Thickness range | 1.65 - 60mm | |

| Packing | in wooden case or pallet | |

| Anticorrosion | Anticorrosion coating | Fusion Bonded Epoxy |

| Anticorrosion Type | Single external/internal/External dual layers | |

| Standard | National standard,company standard | |

| Thickness | As customer's requirements | |

The advantages of antiseptic products

1, the most perfect impact resistance, friction resistance, shock resistance and the covering materials is not easy to be damaged when constructing.

2,highly resisting acid ,alkali and salt and good corrosion resistance .

3,electric insulation,highly electrical-shock resistance.

4,low rate of oozing water .

5,long usage-life.

The usages of antiseptic products

1,on-under ground tubing for gas.

2,tubing for oil tubes and oil -storage groove.

3,safe-guard tubes for electric power and communication.

4,all chemical and industrial tubing.

5,tubes for water -transportation.

6,passing-through pushing tubes.

7,other usages.

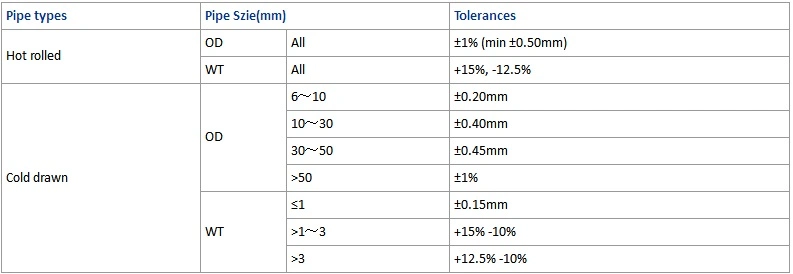

Steel pipe tolerance:

Steel pipe inspection→Steel pipe pre-heating→Steel pipe shot-blasting→Anchor pattern depth/Cleanness inspection→Steel pipe medium→frequency heating→Epoxy powder spraying→Adhesive coating→Polyethylene Wrapping-Water cooling to 60ºC below→Online electric spark→Pipe end treatment→Finished product inspection→Product marking→Certification sticking→In storage

Related Products

• Steel pipe: Black pipe, Galvanized steel pipe, Round pipe, Square pipe, Rectangular pipe, Spiral pipe, etc

• Steel sheet/coil: Hot/Cold rolled steel sheet/ coil, Galvanized steel sheets/coil, PPGI, Checkered sheet, corrugated steel sheet, etc;

• Steel beam: Angle beam, H beam, I beam, C lipped channel, U channel, Deformed bar, Round bar, Square bar, Cold drawn steel bar, etc

FAQ:

Q: What is the minimum order quantity?

A: 5 tons.

Q: What is delivery time?

A: 30 days after deposit. Except for public holidays.

Q: How can you guarantee the quality?

A: We have rigorous quality test system, from raw materials to finished products, the materials must be checked and signed by QC people.

Q: How long can I get a quote?

A: The quotation can be provided not longer than 24 hours on condition that we know all detailed requirements.

Q: Can I get a sample?

A: Yes we offer free samples. Delivery cost is to be paid by clients.

Q: Why can I trust you and place order with you?

A: From 1997 to 2022 our company is with 20 years experience in this industry, we have served clients from more than 100 countries, our company is well-known for its quality and our team win clients' trust by honesty and down to earth business style.