Basic Info.

Model NO.

pipe

Surface

No.1,2b,No.4,Ba,8K Satin,Brush,Hairline,Mirror,Pol

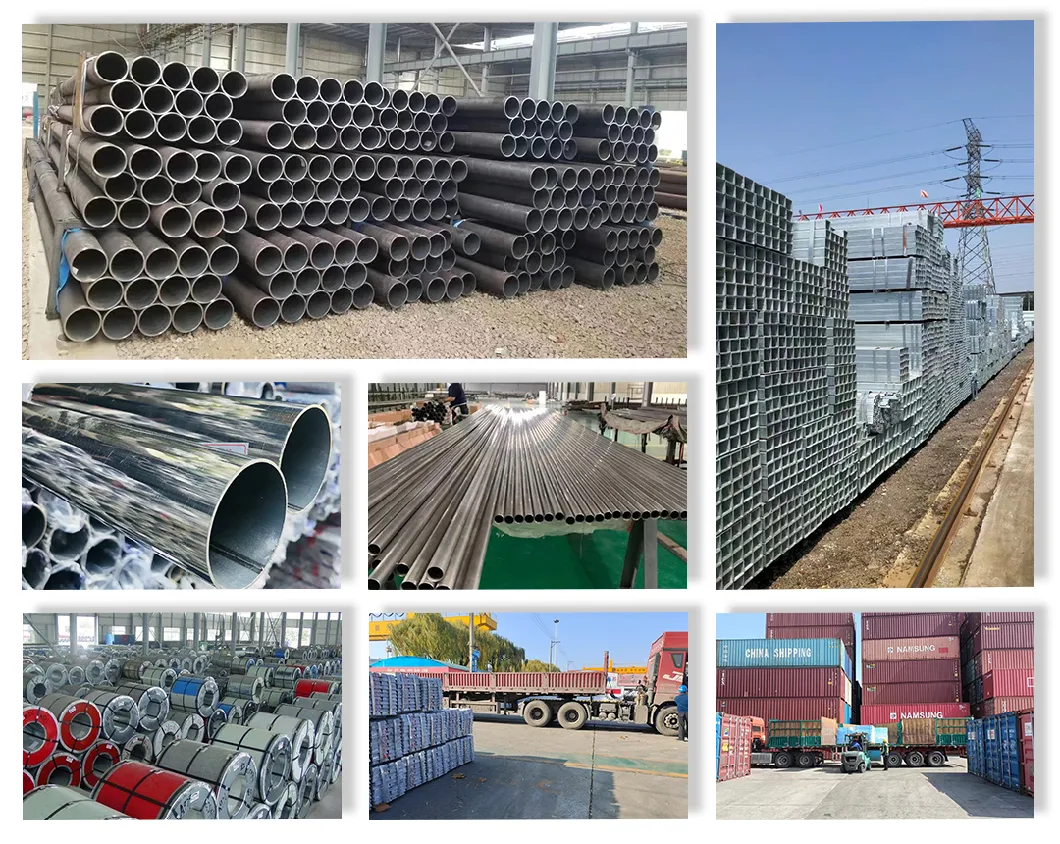

Packing

in Seaworthy Wooden Cases or in Bundles

Length

Max20 Meters

Delivery Time

7-15days

Transport Package

Wooden Carton

Specification

6-219mm

Trademark

BAOGANG

Origin

China

HS Code

8108904010

Production Capacity

20000PCS

Product Description

The difference between titanium and stainless steel:

The difference between titanium and stainless steel:1. Can be distinguished from the color. Titanium is a little darker, revealing a cool color, which feels cool, and titanium is a little darker than steel. The steel is white, the pale kind. The two colors are clearly visible.

2. It can also be distinguished by chemical methods, that is,Titanium does not react, and stainless steel reacts violently as soon as it is put down. The distinction between pure titanium and titanium alloys is difficult to see from the outside.

3. Titanium can draw gray-black marks on ceramic tiles, but stainless steel can't draw marks.

4. Titanium has good corrosion resistance: a dense oxide film is easy to form on the surface of titanium alloy below 550 °C, so it is not easy to be further oxidized, and has high resistance to atmosphere, sea water, steam, and some acids, alkalis, and soft media. Anti-loss thing.

5. Titanium has good thermal strength: the melting point of titanium alloy is 1660°C, which is higher than that of iron, and has high thermal strength. It can work below 550°C and shows good toughness at low temperatures.

6. Titanium processing is difficult: welding, electroplating, and cold stretching are very difficult. Welding and electroplating must be carried out in vacuum or under the condition of being filled with inert gas (vacuum ion plating).

Titanium alloy, as the name suggests, is an alloy formed by adding other elements on the basis of titanium; everyone knows that stainless steel is mainly composed of iron, chromium, and then nickel, manganese, carbon, etc. The amount of these components determines the quality of stainless steel performance difference.

Titanium alloy, as the name suggests, is an alloy formed by adding other elements on the basis of titanium; everyone knows that stainless steel is mainly composed of iron, chromium, and then nickel, manganese, carbon, etc. The amount of these components determines the quality of stainless steel performance difference.In general, titanium alloys have high strength, good heat resistance and strong corrosion resistance.

| Product Name | Titanium tube Round pipe |

| Production Process | Cold Drawn,Cold Rolled,Bright Anneal etc |

| Type | Seamless,welded |

| Standard | ASTM EN DIN GB ISO JIS |

| Tolerance | +/-0.05 ~+/0.02 |

| Surface | Pickling,Bright; No.1,2B,No.4,BA,8K Satin,Brush,Hairline,Mirror,Polished 180 grits,320 grits,400 grits,600 grits,800 grits polished |

| Application | 1. Heat exahanger tube for petrochemical,chemical and ocean development 2. Industrial furnace and heater tubes 3. for gas turbine and prochemical processing 4. Condenser tubes,sulfuric and phosphoric acids tubes,API tubing 5. Construction and ornament 6. Acid production,waste incineration,FGD,paper processing industrial etc |

| Materials | TAD/TA1/TA2/TA3/TA4/TA5/TA6/TA7/TA8 TC1/TC2/TC3/TC4/TC5/TC6/TC7/TC8/TC9/TC10 Grade1/Grade2/Grade3/Grade4/Grade5/Grade6/Grade7/Grade8/Grade9/Grade10/Grade11/Grade12 A-1/A-3/A-4/AB-1/AB-3/AB-4 BT1-00/BT1-0/OT4-0/OT4-1/OT4/BT5/BT5-1/BT6/BT6c/BT3-1/BT9/BT16/BT18/BT19/BT20/BT22 |