Basic Info.

Model NO.

GB/T 5310

Special Use

High-strength Steel Plate, Wear Resistant Steel, Silicon Steel, Cold Heading Steel, Free Cutting Steel, Mold Steel

Application

Boiler Plate

Od

21mm-1219mm

Wt

2mm-100mm

Length

as Per Request

Caps

as Per Request

Terms

Fob/CIF/CFR/EXW

Ends

Plain End/Bevel End

Delivery

7-30days

Surface

Oil/Varnish/3PE/Epoxy

Usage

Heating ,Economizer,Superheater,Petrochemical

Types

Smls

Transport Package

PVC

Specification

alloy pipe

Trademark

EZS

Origin

Tianjin China

HS Code

7304399000

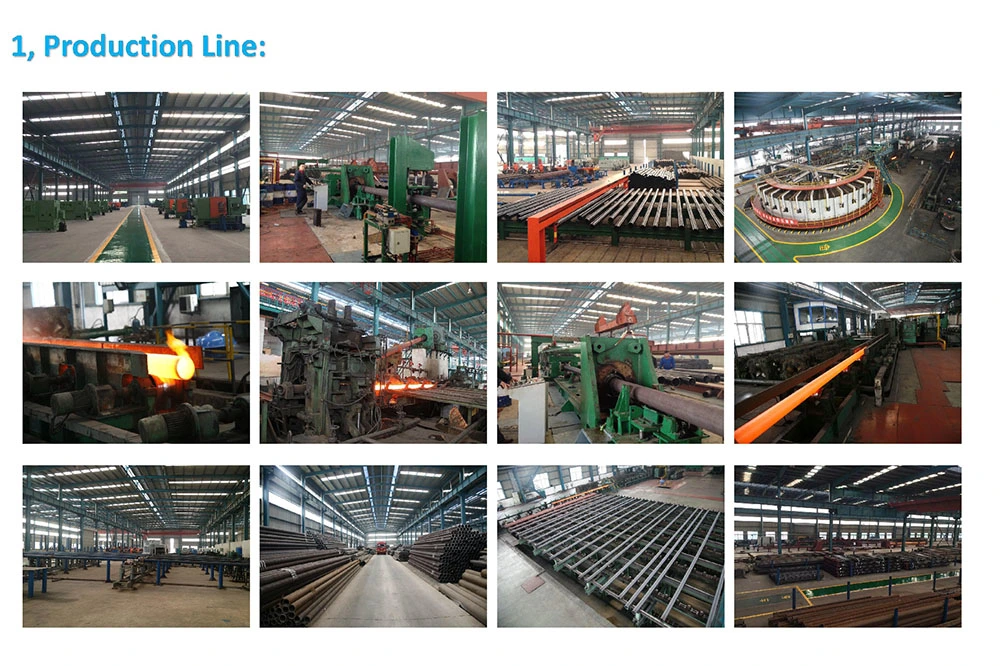

Production Capacity

200000ton/Year

Product Description

| Product Name | Alloy steel pipe,high-pressure boiler tube |

| Production Materials | 16-50Mn,27SiMn,20-40Cr,12-42CrMo 16Mn 12Cr1MoV T91 27SiMn 30CrMo 15CrMo 20G Cr9Mo 10CrMo910 15Mo3 15CrMoV 35CrMoV 45CrMo |

| Outside Diameter Ranges | 21mm-1219mm |

| Wall Thickness Ranges | 2mm to 100mm |

| Length (negotiable) | For 20Ft Container |

| For 40Ft Container | |

| As per request | |

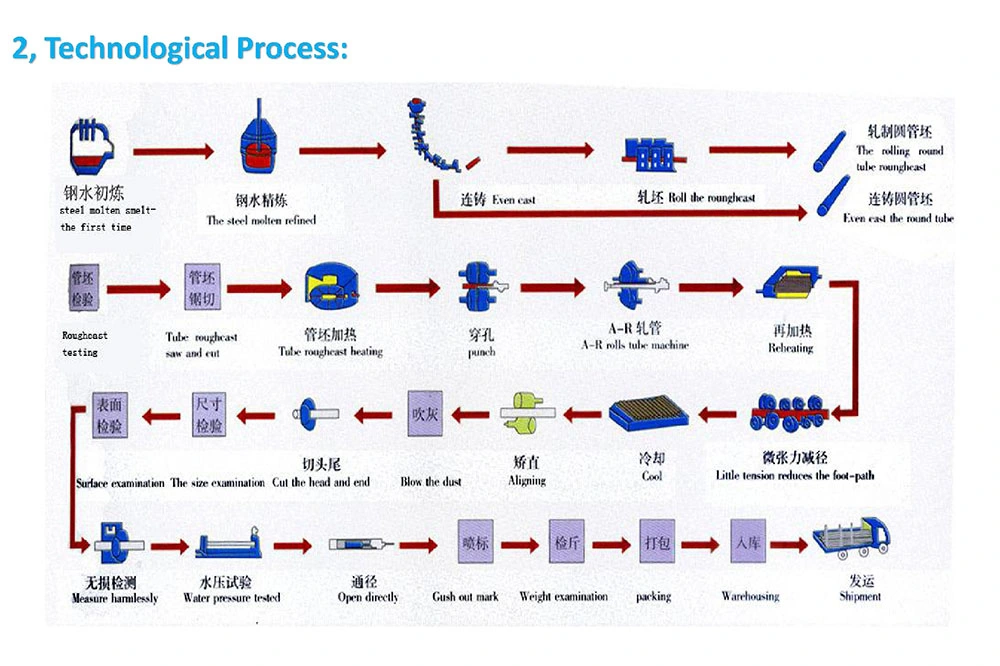

| Pipe Type | Cold Drawn, Hot Rolled |

| Pipe End | 1) 8-60mm Plain End; 2) 60-168.3mm Plain End or Beveled End |

| End protector | 1) Plastic pipe cap; 2) Steel Socket |

| Minimum Order Quantity | 1 ton |

| Packing | Bundled with steel strips |

| Out Surface Treatment | Bared,Black Painted ,varnish,Oil-dip,passivation,passivation,phosphating,shot Blasting |

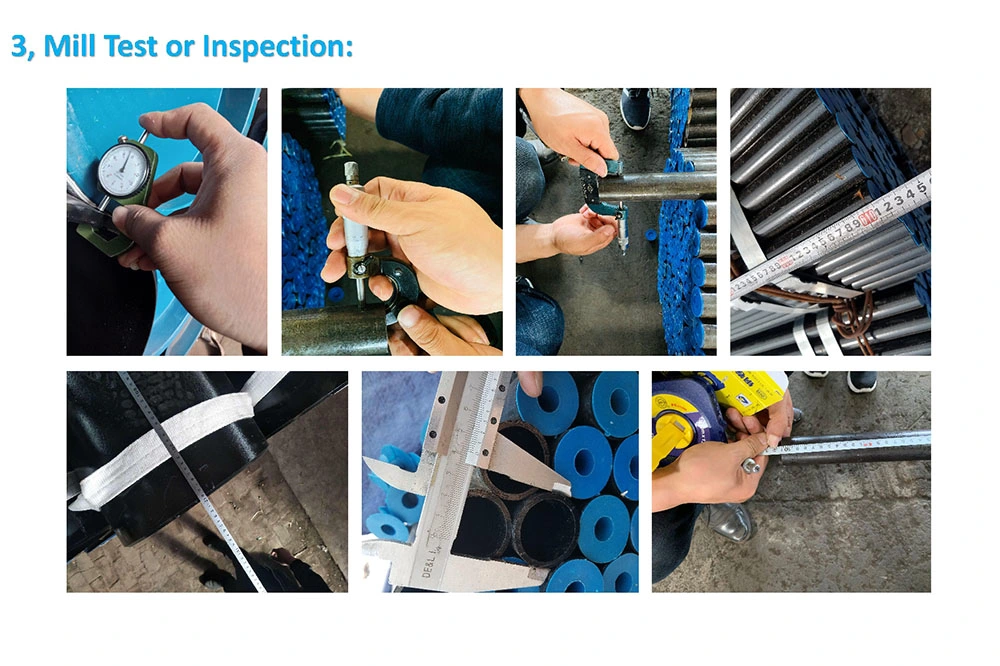

| Inspection | With Hydraulic Testing, Eddy Current, Infrared Test |

| Application | Low-Pressure Liquid, Water, Gas, Oil, Line Pipe, Heat-Transfer Equipment, such as tubular heat exchanger, condenser and superheater, For high, middle, low-pressure boiler and pressure purpose |

| Our advantages | ·Diverse products(Steel pipes, pipe fittings) |

| ·Any third party inspection can be accepted |

| standrads | marks | component(%) | |||||||||||||

| C | Si | Mn | P | S | Cr | Mo | Cu | Ni | V | Al | W | Ti | Nb | N | |

| GB3087 | 10 | 0.07~0.13 | 0.17~0.37 | 0.38~0.65 | ≤0.030 | ≤0.030 | 0.3~0.65 | / | ≤0.25 | ≤0.30 | / | / | |||

| 20 | 0.17~0.23 | 0.17~0.37 | 0.38~0.65 | ≤0.030 | ≤0.030 | 0.3~0.65 | / | ≤0.25 | ≤0.30 | / | / | ||||

| GB5310 | 20G | 0.17~0.24 | 0.17~0.37 | 0.35~0.65 | ≤0.030 | ≤0.030 | ≤0.25 | ≤0.15 | ≤0.20 | ≤0.25 | ≤0.08 | ||||

| 20MnG | 0.17~0.24 | 0.17~0.37 | 0.70~1.00 | ≤0.030 | ≤0.030 | ≤0.25 | ≤0.15 | ≤0.20 | ≤0.25 | ≤0.08 | |||||

| 25MnG | 0.18~0.24 | 0.17~0.37 | 0.80~1.10 | ≤0.030 | ≤0.030 | ≤0.25 | ≤0.15 | ≤0.20 | ≤0.25 | ≤0.08 | |||||

| 15CrMo | 0.12~0.18 | 0.17~0.37 | 0.40~0.70 | ≤0.030 | ≤0.030 | 0.80~1.10 | 0.40~0.55 | ≤0.20 | ≤0.30 | ||||||

| 12Cr2MoG | 0.08~0.15 | ≤0.50 | 0.40~0.70 | ≤0.030 | ≤0.030 | 2.00~2.50 | 0.90~1.20 | ≤0.20 | ≤0.30 | ||||||

| 12Cr1MoV | 0.08~0.15 | 0.17~0.37 | 0.40~0.70 | ≤0.030 | ≤0.030 | 0.90~1.20 | 0.25~0.35 | ≤0.20 | ≤0.30 | 0.15~0.30 | |||||

| 12Cr2MoWVTiB | 0.08~0.15 | 0.45~0.75 | 0.45~0.65 | ≤0.030 | ≤0.030 | 1.60~2.10 | 0.50~0.65 | ≤0.20 | ≤0.30 | 0.28~0.42 | 0.30~0.55 | 0.08~0.15 | B 0.002~0.008 | ||

| 10Cr9Mo1VNb | 0.08~0.12 | 0.20~0.50 | 0.30~0.60 | ≤0.020 | ≤0.010 | 8.00~9.50 | 0.85~1.05 | ≤0.20 | ≤0.40 | 0.18~0.25 | ≤0.015 | 0.06~0.10 | 0.03~0.07 | ||

| ASME SA210 | SA210A-1 | 0.13~0.19 | ≥0.1 | 0.45~0.65 | ≤0.030 | ≤0.030 | |||||||||

| SA210C | 0.18~0.24 | ≥0.1 | 0.80~1.10 | ≤0.030 | ≤0.030 | ||||||||||

| ASME SA213 | SA213 T11 | 0.05~0.15 | 0.50~1.0 | 0.30~0.60 | ≤0.030 | ≤0.030 | 1.00~1.50 | 0.50~1.00 | |||||||

| SA213 T12 | 0.05~0.15 | ≤0.50 | 0.30~0.61 | ≤0.030 | ≤0.030 | 0.80~1.25 | 0.44~0.65 | ||||||||

| SA213 T22 | 0.05~0.15 | ≤0.50 | 0.30~0.60 | ≤0.030 | ≤0.010 | 1.90~2.60 | 0.87~1.13 | ||||||||

| SA213 T23 | 0.04~0.10 | ≤0.50 | 0.10~0.60 | ≤0.030 | ≤0.030 | 1.90~2.60 | 0.05~0.30 | ≤0.030 | 1.45~1.75 | B 0.0005~0.006 | 0.02~0.08 | ≤0.040 | |||

| SA213 T91 | 0.08~0.12 | 0.20~0.50 | 0.30~0.60 | ≤0.020 | ≤0.010 | 8.00~9.50 | 0.85~1.05 | ≤0.40 | 0.18~0.25 | ≤0.015 | 0.06~0.10 | 0.03~0.07 | |||

| SA213 T92 | 0.07~0.13 | ≤0.50 | 0.30~0.60 | ≤0.020 | ≤0.010 | 8.50~9.50 | 0.30~0.60 | ≤0.40 | 0.15~0.25 | ≤0.015 | 1.50~2.00 | B 0.001~0.006 | 0.04~0.09 | 0.03~0.07 | |

| DIN 17175 | ST45.8/ 3 | ≤0.21 | 0.10~0.35 | 0.40~1.20 | ≤0.040 | ≤0.040 | |||||||||

| 15Mo3 | 0.12~0.20 | 0.10~0.35 | 0.40~0.80 | ≤0.035 | ≤0.035 | 0.25~0.35 | |||||||||

| 13CrMo44 | 0.10~0.18 | 0.10~0.35 | 0.40~0.70 | ≤0.035 | ≤0.035 | 0.70~1.10 | 0.45~0.65 | ||||||||

| 10CrMo910 | 0.08~0.15 | ≤0.50 | 0.30~0.70 | ≤0.025 | ≤0.020 | 2.00~2.50 | 0.90~1.10 | ≤0.30 | ≤0.30 | ≤0.015 |