- Overview

- Product Parameters

Basic Info.

Product Description

| Product Description |

ASTM A213 T2, T11, T12, T22, T91, and T92 alloy steel tubes have excellent performance in high-temperature and high-pressure environments. They are widely used in industries such as petroleum, chemical, power, and nuclear energy for boilers, heat exchangers, and high-temperature equipment.

T2 alloy steel pipe is a low alloy steel pipe containing a small amount of chromium and molybdenum. It is mainly used in industries such as petroleum refining, chemical engineering, and heat exchangers.

T11 alloy steel pipe is a medium carbon-molybdenum alloy steel pipe with good high-temperature resistance and creep resistance. It is commonly used in high-temperature and high-pressure equipment in industries such as petroleum, chemical, and power, such as boilers and heat exchangers.

T12 alloy steel pipe is a low carbon-molybdenum alloy steel pipe with good heat resistance and corrosion resistance. It is widely used in high-temperature equipment in chemical, petroleum, and power industries.

T22 alloy steel pipe is a low carbon-chromium-molybdenum alloy steel pipe with excellent heat resistance and oxidation resistance. It is mainly used in high-temperature and high-pressure boilers, heaters, and heat exchangers.

T91 alloy steel pipe is a high chromium-molybdenum-vanadium alloy steel pipe with excellent high-temperature and creep resistance. It is widely used in supercritical and ultra-supercritical boilers, as well as high-temperature equipment in the chemical and energy industries.

T92 alloy steel pipe is a high chromium-molybdenum-vanadium-manganese alloy steel pipe with outstanding high-temperature resistance and oxidation resistance. It is mainly used in supercritical and ultra-supercritical boilers and is widely applied in the chemical and energy industries.

| Detailed Photos |

ASTM A213 provides specifications and requirements for chromium-molybdenum alloy steel seamless and welded tubes. These tubes are commonly used in industries such as petroleum, chemical, and power, where high temperatures and pressures are involved. ASTM A213 covers a range of different grades and materials of steel tubes, including T2, T5, T9, T11, T12, T22, T91, and more. The standard specifies requirements for the chemical composition, mechanical properties, pressure resistance, visual inspection, and other aspects of the tubes. By complying with ASTM A213, the quality and performance of the steel tubes used under harsh conditions are ensured to meet high standards.

| Product Parameters |

| Product Name | alloy steel pipe / boiler tube |

| Standard | API 5L ASTM A106/A53 ASTM A519 JIS DIN 2391 EN10305 ASMESA106 SA192 SA210 SA213 SA335 ASTM A179 etc |

| Material | 40Cr 45# 20# 1045 30CrMO 4130 4135 4140 SCr440 16Mn 42CrMO 35CrMO etc. |

| Outer diameter | 25 - 545 mm |

| Wall thickness | 2.5 - 120 mm |

| Length | 3-12m, random or fixed, as the clients' requests |

| Technology | Hot Rolled/Hot expanded/Cold Drawn |

| Application | Structure pipe; High and low pressure boiler tube; Liquid delivery; Seamless steel pipe for petroleum cracking ,Oil pipe,Gas pipe |

| Steel Grade | Chemical Composition% | |||||||

| C | Si | Mn | P, S Max | Cr | Mo | Ni Max | V | |

| T2 | 0.10~0.20 | 0.10~0.30 | 0.30~0.61 | 0.025 | 0.50~0.81 | 0.44~0.65 | - | - |

| T11 | 0.05~0.15 | 0.50~1.00 | 0.30~0.60 | 0.025 | 1.00~1.50 | 0.44~0.65 | - | - |

| T12 | 0.05~0.15 | Max 0.5 | 0.30~0.61 | 0.025 | 0.80~1.25 | 0.44~0.65 | - | - |

| T22 | 0.05~0.15 | Max 0.5 | 0.30~0.60 | 0.025 | 1.90~2.60 | 0.87~1.13 | - | - |

| T91 | 0.07~0.14 | 0.20~0.50 | 0.30~0.60 | 0.02 | 8.0~9.5 | 0.85~1.05 | 0.4 | 0.18~0.25 |

| T92 | 0.07~0.13 | Max 0.5 | 0.30~0.60 | 0.02 | 8.5~9.5 | 0.30~0.60 | 0.4 | 0.15~0.25 |

|

|

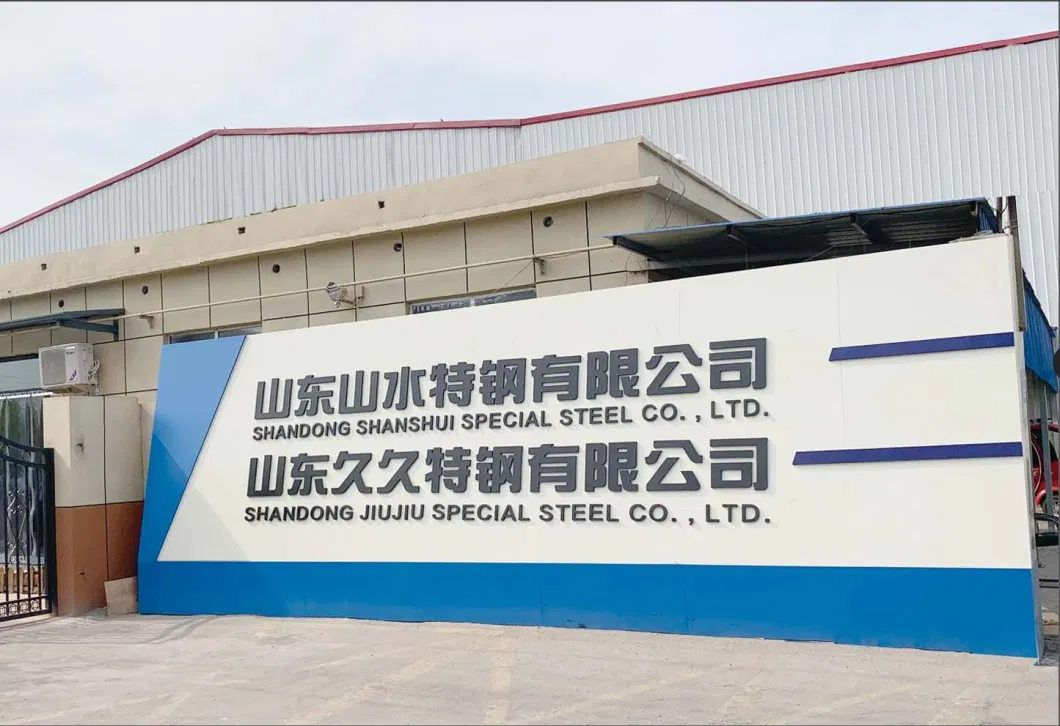

Shandong Shanshui Special steel pipe Co.,LTD. Our company was founded in 2014, The headquarters is located in 14th floor, Rongfu Center, Huangshan Road, Liaocheng ,Shandong Province,China.

Shandong Shanshui Special steel pipe Co.,LTD. Our company was founded in 2014, The headquarters is located in 14th floor, Rongfu Center, Huangshan Road, Liaocheng ,Shandong Province,China.We specialized in the research and development,production,sales and application promotion of seamless steel pipe. We can provide customer-required Standard,Specification,Material,

Application of Carbon steel tube,Alloy steel tube and their machined products etc.

We have ten years of industry experience, the annual output of the factory is 250,000 tons, non-standard steel tube, super thick wall steel tube, alloy steel tube, super long steel tube, fixed size steel tube are our production advantages.

· 50 production workshop · 76 production workshop · 90 production workshop

Our factory can provide customers with product testing and steel tube machining services,

"OWN PRODUCTION & SALES" production mode, flexible to meet customer needs, for customers to save money.

Our factory's product quality is guaranteed, workshop production control is strict, coordination ability is strong, timely delivery.

Excellent quality and perfect service are the premise and guarantee to create maximum value for customers!

| FAQ |

What kind of company is Shandong Shanshui Special Steel Co., LTD.?

Shandong Shanshui Special Steel Co., Ltd. is a reputable manufacturer and supplier of top-quality steel products in Shandong province, China. With our dedication to excellence, we specialize in producing a wide range of steel pipes including seamless, welded, and alloy steel pipes.

Our company is committed to providing customers with high-quality and reliable steel products. We have built a strong reputation both domestically and internationally for our consistent product quality and customer satisfaction.

Where is the factory of Shandong Shanshui Special Steel Co., LTD.?

We have 50, 76, 90, a total of three large hot-rolled seamless steel pipe production lines, and there are 10 fine rolled seamless steel pipe production lines. Among them, the 90-line configuration of Assel limited mandrel rolling machine is the strongest three-roll rolling capacity in China, and with the two-roll sizing machine, it is the only production line that can produce ultra-thick wall specifications and ultra-long steel pipes. We can accept non-standard steel pipe, super thick wall alloy steel pipe, we produce and sell by ourselves, fast delivery, to provide efficient solutions for customers' steel needs.

How about our product quality and after-sales service?

My factory finishing rolling tube in Liaocheng first product quality assurance service, that is: product quality problems, our company can undertake replacement, return and other quality assurance services. Execution in the workshop: process card, work order, 2-hour quality inspection, entrance inspection, exit inspection, etc., to ensure that unqualified products do not produce and do not leave the factory.

What can you buy from us?

Shandong Shanshui Special Steel Co., Ltd. can provide various types of steel pipes, including but not limited to:

1.Seamless steel pipes: Suitable for high temperature, high pressure, and special applications in industries such as petroleum,natural gas, chemical, and power.

2.Welded steel pipes: Suitable for general industrial, construction, and structural purposes, such as buildings, bridges, and machinery manufacturing.

3.Alloy steel pipes: Treated with alloy elements, these pipes have high strength, wear resistance, and corrosion resistance. They are widely used in industries such as petroleum, chemical, power, and aerospace.

4.Oil pipes: Used for oilfield development and oil transportation, these pipes are resistant to high temperatures and corrosion.

5.Gas pipes: Used for natural gas transportation, these pipes have high pressure and corrosion resistance.

6.Hydraulic support pipes: Used in mining, construction, and mechanical equipment as hydraulic supports, these pipes have high strength and corrosion resistance.

In addition, we also provide customized steel pipe products. We can manufacture pipes with special specifications, materials, and processing requirements based on customer needs.