- Overview

- Product Description

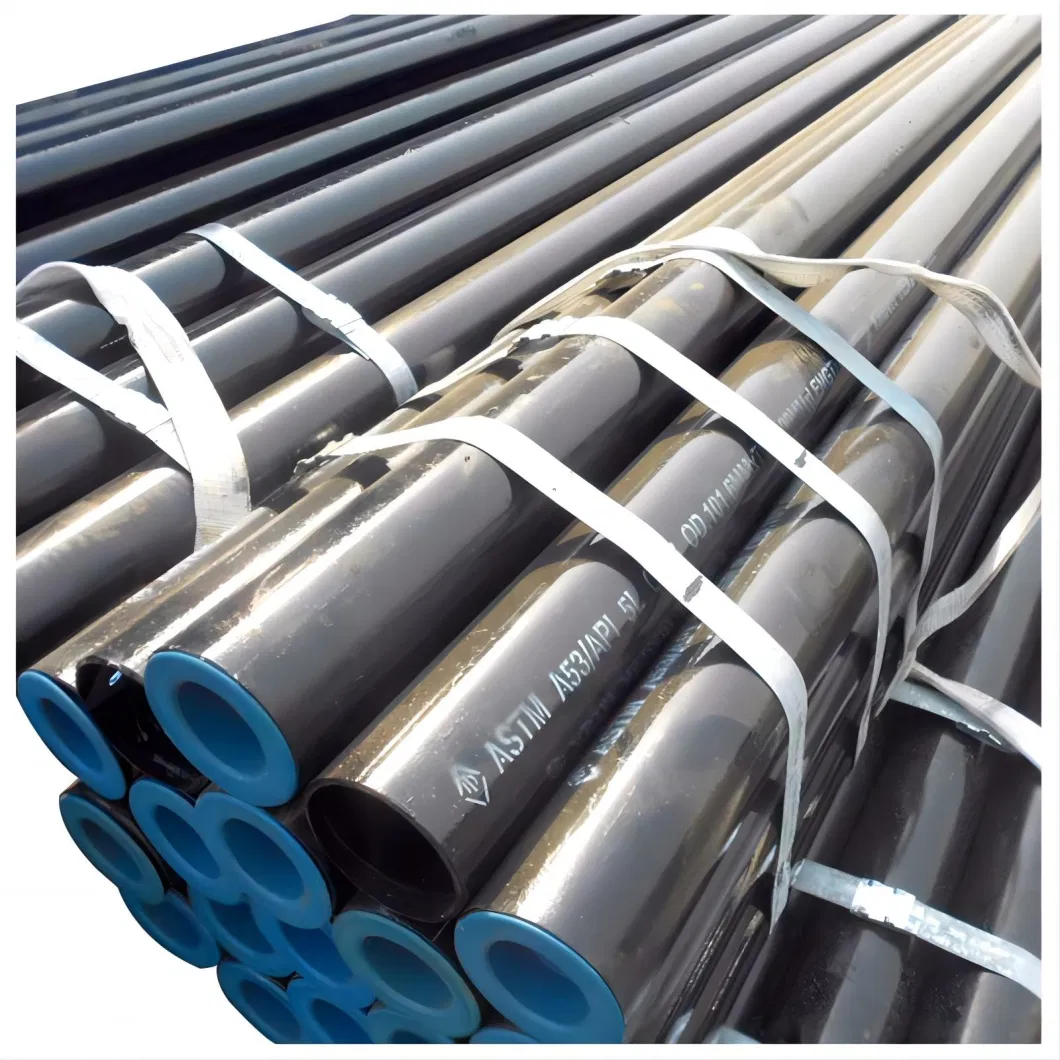

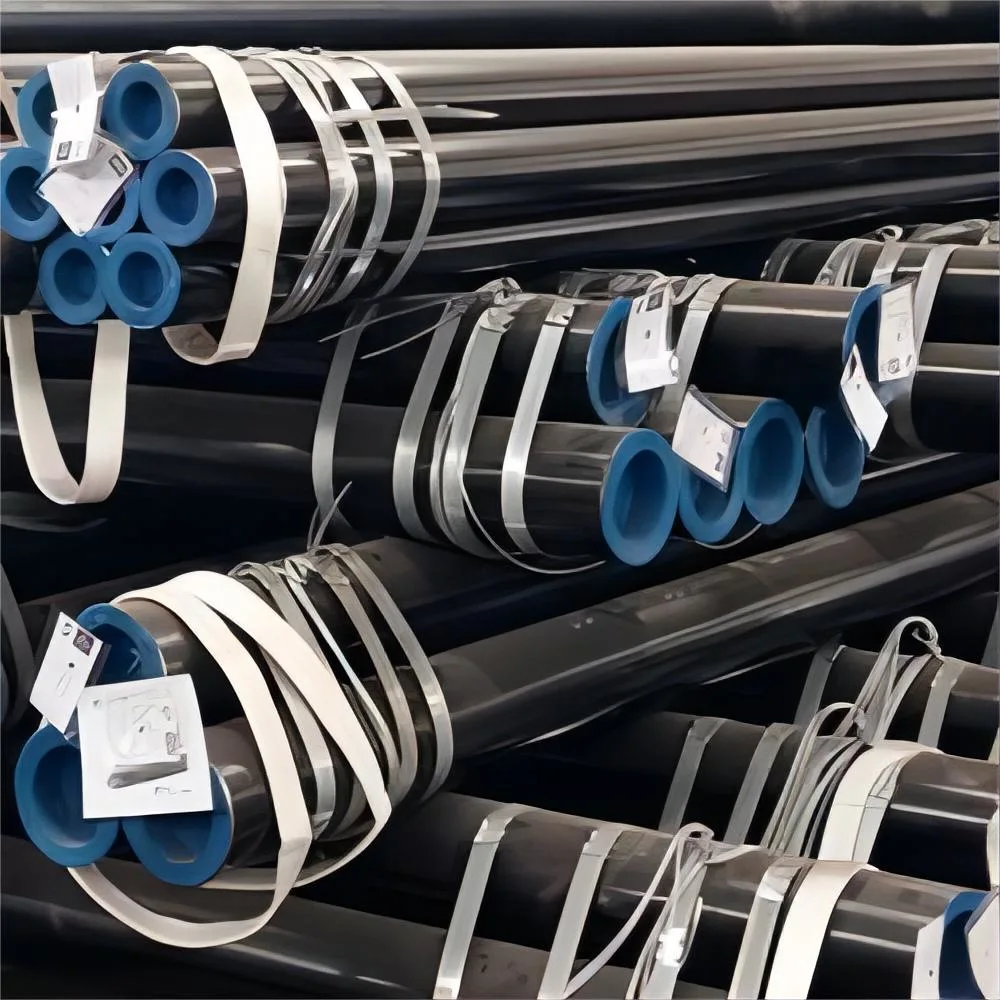

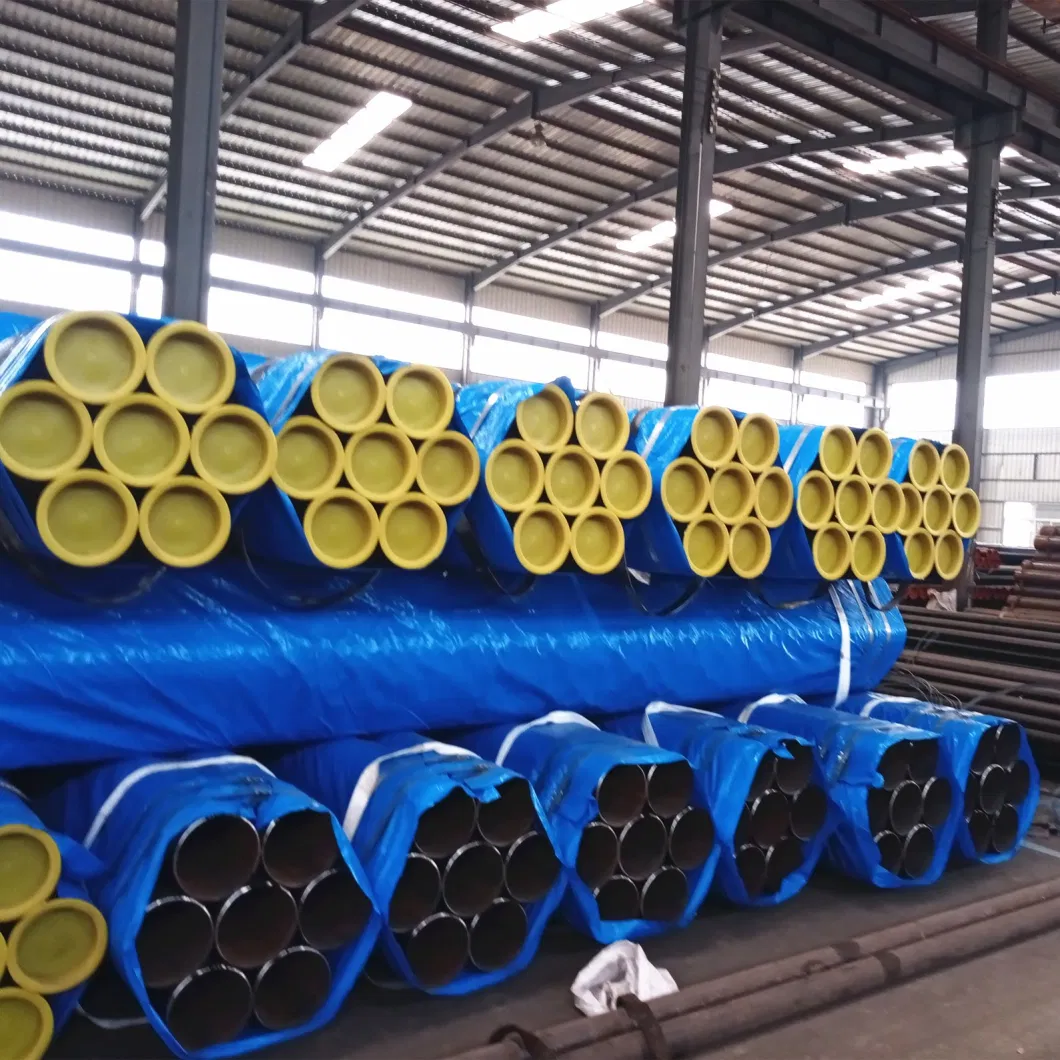

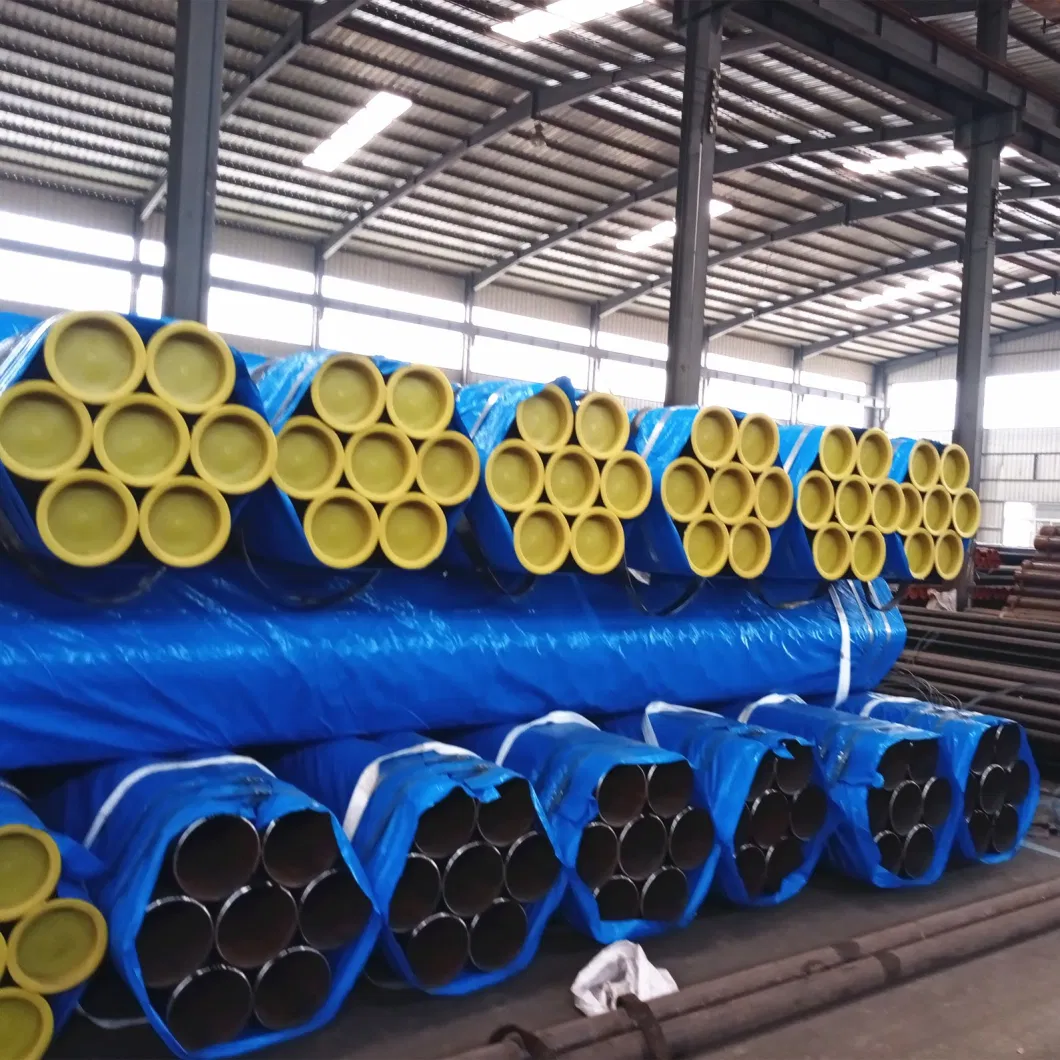

- Detailed Photos

- Product Parameters

- Certifications

- Packaging & Shipping

- Company Profile

- FAQ

Basic Info.

Product Description

We Supply Alloy Steel Seamless Pipes and Tubes in ASTM A335 Grade P5, ASTM A335 Grade P9, ASTM A335 Grade P11, ASTM A335 Grade P22, ASTM A335 Grade P91, ASTM A213 Grade T5, ASTM A213 Grade T9, ASTM A213 Grade T11, ASTM A213 Grade T22, ASTM A213 Grade T91.

ASTM A335 Pipe (ASME S/A335, Chorme-Moly) is a seamless ferritic Alloy-Steel Pipe for high temperature service. Pipe ordered to this specification shall be suitable for bending, flanging (vanstoning), and similar forming operations, and for fusion welding. Sometimes referred to as "P Grade", Chrome Moly Pipe is popular in P-Grades P5, P9, P11, P22, and P91. The most common use of grades P11, P22, and P91 is in the power industry and petro-chemical plants, Grades P5 and P9 are commonly used in refineries.

A335 is often called chrome moly pipe because of the chemical makeup of Molybdenum (Mo) and Chromium (Cr). Molybdenum increases the strength of steel as well as the elastic limit, resistance to wear, impact qualities, and hardenability. Moly increases the resistance to softening, restrains grain growth and makes chromium steel less susceptible to embrittlement. Moly is the most effective single additive that increases high temperature creep strength. It also enhances the corrosion resistance of steel, and inhibits pitting. Chromium (or chrome) is the essential constituent of stainless steel. Any steel with 12% or more Chrome is considered stainless. Chrome is virtually irreplaceable in resisting oxidation at elevated temperatures. Chrome raises the tensile, yield, and hardness at room temperatures. The composition chrome moly alloy steel pipe make it ideal for use in power plants, refineries, petro chemical plants, and oil field services where fluids and gases are transported at extremely high temperatures and pressures.

ASTM A213 seamless pipes tubes Standard Specification for Seamless Ferritic and Austenitic Alloy-Steel Boiler, Superheater, and Heat-Exchanger Tubes This specification covers seamless ferritic and austenitic steel boiler, superheater, and heat-exchanger tubes. Grades containing the letter H in their designation have requirements different from those of similar grades not containing the letter H. These different requirements provide higher creep-rupture strength than normally achievable in similar grades without these different requirements. The tubes shall be made by the seamless process and shall be either hot finished or cold finished, as specified. Grade TP347HFG shall be cold finished. Heat treatment shall be done separately and in addition to heating for hot forming. The ferritic alloy and ferritic stainless steels shall be reheated. On the other hand, austenitic stainless steel tubes shall be furnished in the heat-treated condition. Alternatively, immediately after hot forming, while the temperature of the tubes is not less than the minimum solution temperature, tubes may be individually quenched in water or rapidly cooled by other means. Tension test, hardness test, flattening test, and flaring test shall be done to each tube. Also, each tube shall be subjected to the nondestructive electric test or hydrostatic test.

| Grade | SA 213 T2 Tube (With IBR Certificate) |

| UNS | UNS K11547 |

| SA 213 T2 Tube Size Range |

|

| SA 213 T2 Heat Exchanger and Boiler Tube | up to 19.6 meters |

| ASTM A213 T2 Furnace Tubes | 2"-9" diameters, Length: up to 70ft |

| SA 213 T2 Welded Tubes | 1/2" NB - 24" NB |

| Alloy Steel T2 Finned Tubes | (16 or 19 fins/ inch) |

| Wall Thickness of SA 213 T2 Tube | 4.5mm to 60mm |

| SA 213 Gr T2 Tube end | BE -Beveled end, BLE -Bevel large end, BSE -Bevel small end, TOE -Treaded One End, BOE-Beveled One End, TBE -Treaded Both Ends, Coupled, BBE -Bevel both ends, PBE -Plain Both Ends, POE -Plain One End |

| A213 T2 Tube Length | 12000mm, SRL, 20FT, Custom Length, Single Random Length (SRL), Double Random Length (DRL), 3000mm, 2000mm, 6000mm, DRL, 40FT |

| SA 213 T2 Tube Wall Thickness | SCH-80S, SCH160, SCH-10S, SCH-80, SCH-40, SCH-10, SCH-40S, SCH-XXS, SCH-STD, SCH-XS, SCH-5, SCH-5S |

| Surface Treatment of SA213 T2 Tube |

|

| Processing Service of T2 Steel Tube | Decoiling, Punching, Cutting, Painting, Coating, Welding, Bending |

| Marking by T2 Tube suppliers |

SA 213 T2 Seamless Tube Marking Sample: Manufacturer Name ASTM A213 T2 2" x 0.250" x 20" TUBE SEAMLESS HEAT NO. XXXX |

Different methods used by SA 213 T2 Tube manufacturers | Fabricated, Electric Resistance Welded (ERW), Welded, Extrusion, Longitudinally Submerged Arc Welded (LSAW), Electro Fusion Seam Welded (EFSW), CDW, 100% X Ray/ Gamma Ray Welded, Hot Finish Seamless (HFS), Horizontal Submerged Arc Welded (HSAW), Submerged Arc Welded (SAW), Cold Drawn Seamless (CDS), Seamless |

| Approvals | ONGC, BP, PED, EIL, KNPC, IBR, ISO 17025 for Laboratories, Saudi Aramco, AD2000, Merkblatt W0, NORSOK M-650, Shell, L&T, PED 97/23/EC, HAF 604 |

| Origin of ASTM A213 T2 Tube material | USA, Japanese, Latin-American, Asian, Africa, UK, European, American, Korean, Gulf, Chinese, Russian, Indian, Japan, Ukraine |

| Ask for these certificates from SA 213 T2 Tube suppliers | Sour-Service, SSC, IBR, NACE, EN-10204:3.2, HIC, EN-10204:3.1 |

| Equivalent Standards | SAE, GB, AWWA, EN, DIN, ISO, SS, UNI, GOST, KS, CSA, JIS, IS, API, BS, ASTM, AISI, NFA, ANSI |

| Various Testing performed by T2 Boiler Tube manufacturers | Ultrasonic Test, Impact, Ferrite, Straightness, Charpy V Impact Test, Fine Grain, Ultrasonic, HIC- Hydrogen-induced Cracking, H2 SERVICE, TM0284, Micro, Metallurgical & Stereo Microscopy, Hardness, Flux Leakage examination or Magnetic Flaw detection, Mechanical, Hardness Test, SSC- Sulfide Stress Corrosion Cracking, Hydro test, IGC- Intergranular Corrosion Test, Salt Spray Test to test Phosphating, Tensile, Radiography, Eddy current, TM0177, Stress , Positive Material Identification (PMI), Bend TestBend test / Guided Bend, NACE MR0175, Surface Roughness Test, Macro, Chemical, Burst Test, Non Destructive Testing , IBR, Creep, Charpy V-Notch Test |

| Additional Services and Facility | Sawing, Cutting, Polishing, Laser/ Water Jet Cutting, Threading, Beveling, Tapping |

| Material Test Certificate (MTC) provided by T2 Tubing suppliers | PED, EN 10204 3.1, Radiographic Testing (RT), ISO 14001:2015, IBR, NDE, Ultrasonic Testing (UT), EIL, ISO 9001:2005 |

| Supplier of SA 213 T2 Tube in various shapes | Round, Hollow, Hydraulic, Triangle, Square, Rhomboid, Oval, Semi-Rhomboid, Rectangle Hollow, Elliptical, U-Bend, Semi-Round, Semi-oval |

| Product Name | ASTM SA 213 T2 ASTM A335 Grade P9 Heat Exchanger Tube Hot Finished Pipe Ferritic Alloy Mainly Used For Making Steel Boiler Tube |

| Standard | ASME-SA106, ASME SA-192M, ASME SA-209M, ASME SA-210M, SAME SA-213M, SAEM SA333M, ASTM A106M, ASTM A192M, ASTM A210M, ASTM A213M, ASTM A335M, EN10216-2, DIN 1715, JIS G 3456,JIS G 3461, JIS G 3462, GB 3087,GB 5310, GB 6479, GB9948, GB/T 13296 |

| Grade | SA-106B/C, SA-192, SA-179,SA-210A1/C,ASTM A335 Grade P5, ASTM A335 Grade P9, ASTM A335 Grade P11, ASTM A335 Grade P22, ASTM A335 Grade P91, ASTM A213 Grade T5, ASTM A213 Grade T9, ASTM A213 Grade T11, ASTM A213 Grade T22, ASTM A213 Grade T91.10, 20, 20G, 20MnG, 25MnG P265GH, P195GH, P235GH, ST35.8, DT45.8 |

| Usage | For manufacture wall panel, economizer, reheater,superheater and steam pipeline of boilers |

| MOQ | 5Tons/Size |

| Dimension | 10.00mm~1422.00mm |

| End Tpye | Plain end |

| Surface | Bare, Slightly Oiled, Customed |

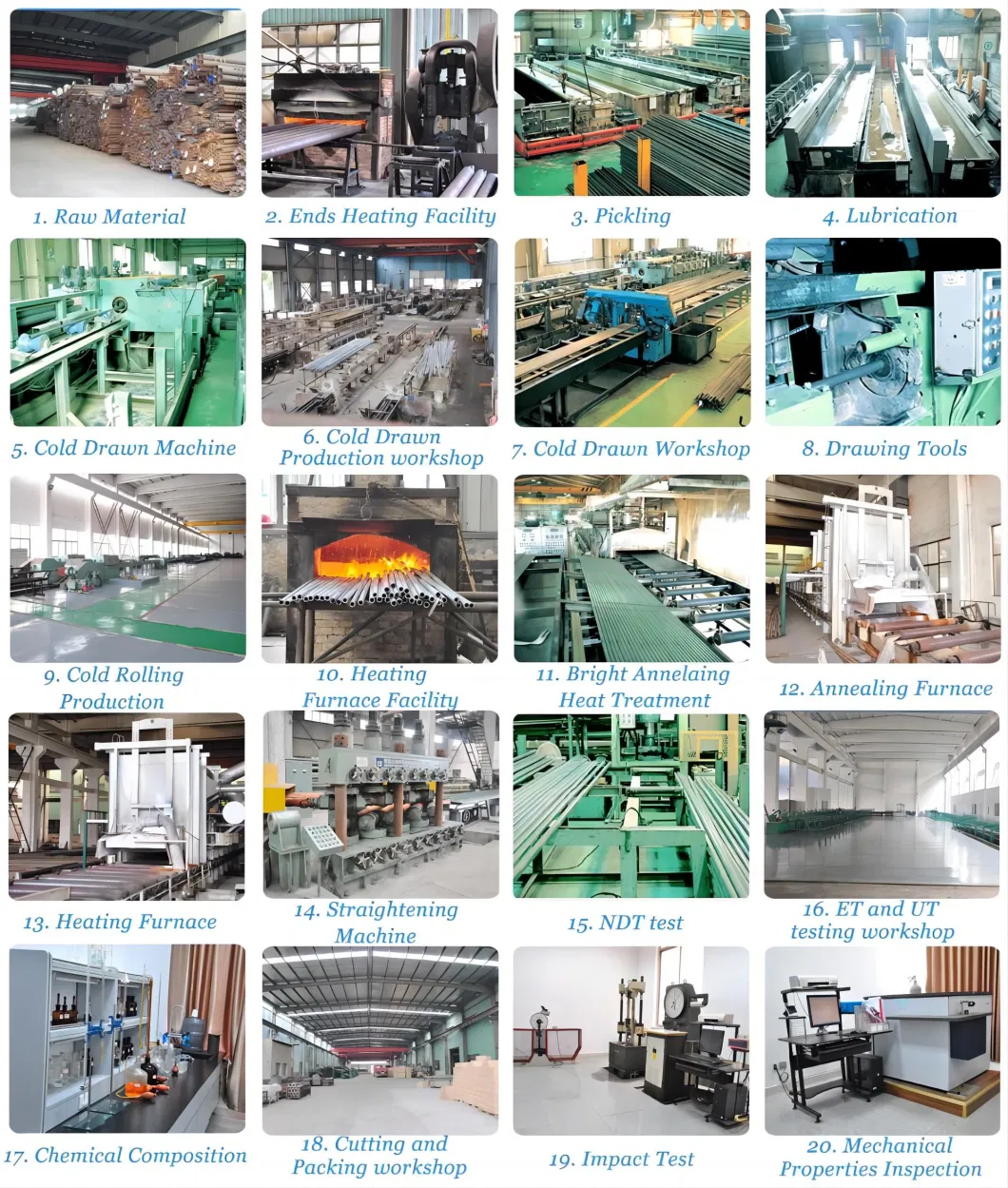

Production Line

Shandong Xuanlin Metal Materials Co., Ltd., was founded in 2008, covers an area of 10, 000 square metres. We are a professional manufacturing and trading company of metal building materials. We currently sell domestically and export worldwide to places such as Africa, North America and the Middle East. Our main products are aluminum foil, electrical cable, copper tube, boiler tube, casing pipe, honed tube, steel wires, PPGI/gi coil, galvanized pipe, steel structures. We have more than 30 production lines which can produce customize according to your requirements.

We ensure product quality through systematic testing with technically advanced equipment. Our company has a rang of well established long-term relationships with many domestic steel companies including Bao Steel Group, Hengyang Group, Yieh Phui(China) and Ma Steel Trading. Our advantage is that we are close to national highways and high speeds, 100 kilometers from Jinan Airport and 350 kilometers Tianjin Port...The benefits of light weight, low cost, high corrosion resistance and easy installation with short construction periods have LED to steel structures becoming more widly used in modern building construction with varied applications such as factory workshops, supermarkets, cold storage rooms, plazas, villas and more.

We look forward to building successful business relationships with customers around the world.

Q. Are you a factory or a pure trading company?

A: We are a factory.

A: for the same quality, our price is lower, for the same price, our quality is the best better.

Q. What are your company's strengths?

A: Factory spot, competitive prices, excellent quality, support factory inspection, video call at any time, technical support in 24/7. Simultaneously, we have participated in many international projects.

Q. Whether to support OEM or ODM?

A: We welcome customers to cooperate with us by OEM or ODM. We have a professional technical team, can be customized according to drawings or requirements.

Q. What trade terms do you usually use?

A: We use FOB, CIF, C&R, DDU, DDP.

Q. What is your usual delivery time?

A: From the execution date of the PI, spot products will be delivered within 3 days, and customized products within 15 days. Special circumstances, please communicate again. All our products have strict quality inspection before they leave the factory, to ensure that you receive the goods with excellent quality.

Q. What are your terms of payment?

A: We use TT and LC, or any other payment method available.