- Overview

- Product Description

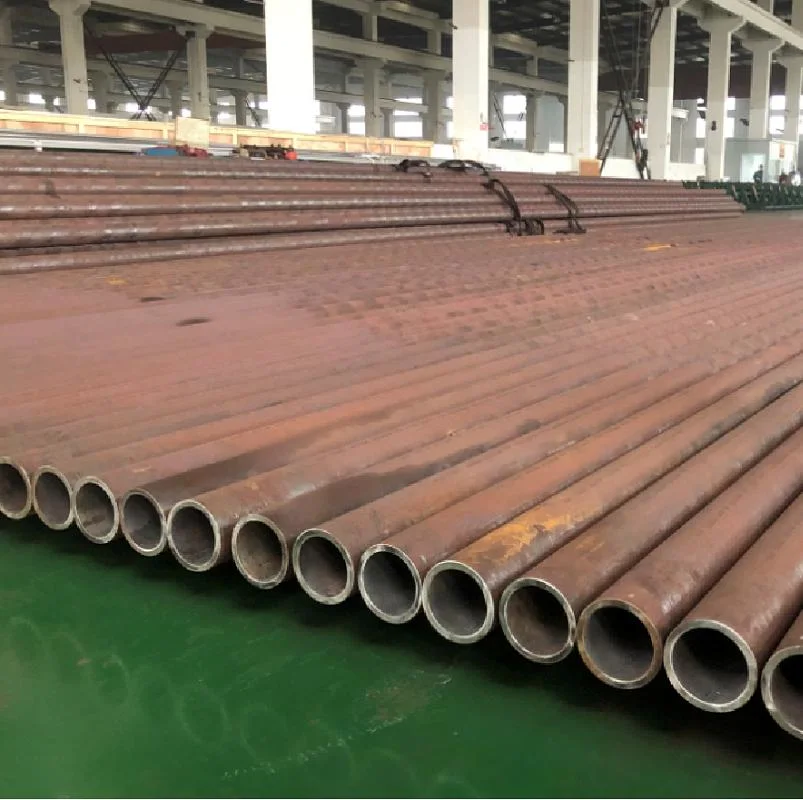

- Detailed Photos

Basic Info.

Product Description

GB 5310 Alloy Round Seamless Steel Tube For Boiler Application

We are a reputable and experienced manufacturer specializing in the production of GB 5310 tubes. With a dedicated team of experts and advanced equipment, we are able to guarantee the quality and performance of our tubes. Our tubes are widely used in various industries, including the power, petrochemical, and construction sectors. We pride ourselves on our commitment to meeting the needs of our clients and providing them with the best possible solution for their specific application.

What we can do?

Forming: Hot Rolled, Cold Rolled, Cold DrawnSizing: OD 10-850 ; WT 1-100

Heating: Annealed, Normalized, Quenched and tempered

Surface: Black, Paint, Polished

Inspection: 3.1 or 3.2 certificate

Chemical Composition of GB 5310 tubes

| Grade | Chemical Composition/% | |||||||

| C | Si | Mn | Cr | Mo | V | P | S | |

| Max. | ||||||||

| 20G | 0.17 - 0.23 | 0.17 - 0.37 | 0.35 - 0.65 | - | - | - | 0.025 | 0.015 |

| 20MnG | 0.17 - 0.23 | 0.17 - 0.37 | 0.70 - 1.00 | - | - | - | 0.025 | 0.015 |

| 25MnG | 0.22 - 0.27 | 0.17 - 0.37 | 0.70 - 1.00 | - | - | - | 0.025 | 0.015 |

| 15MoG | 0.12 - 0.20 | 0.17 - 0.37 | 0.40 - 0.80 | - | 0.25 - 0.35 | 0.025 | 0.015 | |

| 20MoG | 0.15 - 0.25 | 0.17 - 0.37 | 0.40 - 0.80 | - | 0.44 - 0.65 | - | 0.025 | 0.015 |

| 12CrMoG | 0.08 - 0.15 | 0.17 - 0.37 | 0.40 - 0.70 | 0.40 - 0.70 | 0.40 - 0.55 | - | 0.025 | 0.015 |

| 15CrMoG | 0.12 - 0.18 | 0.17 - 0.37 | 0.40 - 0.70 | 0.80 - 1.10 | 0.40 - 0.55 | - | 0.025 | 0.015 |

| 12Cr2MoG | 0.08 - 0.15 | <0.50 | 0.40 - 0.60 | 2.00 - 2.50 | 0.90 - 1.13 | - | 0.025 | 0.015 |

| 12Cr1MoVG | 0.08 - 0.15 | 0.17 - 0.37 | 0.40 - 0.70 | 0.90 - 1.20 | 0.25 - 0.35 | 0.15 - 0.30 | 0.025 | 0.01 |

Mechanical Property of GB 5310 tubes

| Grade | Property | Impaact (kv2)/J | Hardness | |||||

| Tensile strength MPa | Yield strength MPa | Elongation A/ % | L | T | HBW | HV | ||

| Longitudinal | Transverse | |||||||

| Min. | ||||||||

| 20G | 410-550 | 245 | 24 | 22 | 40 | 27 | 120 -160 | 120-160 |

| 20MnG | 415-560 | 240 | 22 | 20 | 40 | 27 | 125 -170 | 125-170 |

| 25MnG | 485-640 | 275 | 20 | 18 | 40 | 27 | 130-180 | 130-180 |

| 15MoG | 450-600 | 270 | 22 | 20 | 40 | 27 | 125 -180 | 125-180 |

| 20MoG | 415-665 | 220 | 22 | 20 | 40 | 27 | 125-180 | 125-180 |

| 12CrMoG | 410-560 | 205 | 21 | 19 | 40 | 27 | 125 -170 | 125-170 |

| 15CrMoG | 440-640 | 295 | 21 | 19 | 40 | 27 | 125 -170 | 125-170 |

| 12Cr2MoG | 450-600 | 280 | 22 | 20 | 40 | 27 | 125-180 | 125-180 |

| I2Cr1MoVG | 470-640 | 255 | 21 | 19 | 40 | 27 | 135-195 | 135-195 |

What is GB 5310 tubes?

GB 5310 tubes are a type of high-quality steel tubes that are used in high-pressure and high-temperature environments. These tubes have a high tensile strength, good toughness, and excellent resistance to corrosion and wear. They are commonly used in a wide range of industries, including the petrochemical, power generation, transportation, and construction sectors.GB 5310 tubes are typically made from high-quality carbon steel or alloy steel, which are then processed and treated to meet the requirements of specific applications. The tubes are usually seamless, with a diameter range from a few millimeters to several centimeters.

To meet the high-pressure and high-temperature requirements, GB 5310 tubes undergo a series of heat treatments and strengthening processes to enhance their mechanical properties and corrosion resistance. For example, they may undergo annealing, quenching, tempering, and shot peening to optimize their microstructure and mechanical properties.

Why choose GB 5310 tubes?

The main advantage of GB 5310 tubes is their high-temperature resistance. The tubes can withstand temperatures up to 500°C, making them suitable for use in high-temperature applications. This high-temperature resistance makes the tubes more efficient and cost-effective compared to other types of tubes.Another advantage of GB 5310 tubes is their good welding performance. The tubes are easy to weld, and the resulting welds have good mechanical properties and toughness. This makes the tubes easy to manufacture and install, and ensures the structural integrity of the finished product.

GB 5310 tubes are also resistant to corrosion. The tubes are made of high-quality steel, which is less susceptible to corrosion than other types of metals. This makes the tubes suitable for use in corrosive environments, such as those with acids or salts.

Finally, GB 5310 tubes are reliable and safe. The tubes have met all the relevant national standards and regulations, ensuring their quality and safety. This makes the tubes suitable for use in critical applications, such as those in the transportation and power generation industries.

Application of GB 5310 tubes

GB 5310 Steel pipe is widely used in petrochemical industry, thermal power generation and other fields, with excellent high temperature and high pressure resistance, can meet the use of high temperature and high pressure conditions. The following will introduce the application of GB 5310 steel pipe from two aspects of petrochemical industry and thermal power generation respectively.

1. petrochemical engineering

In the petrochemical industry, the high temperature and high pressure conditions are inevitable. GB 5310 Steel pipe, as a high strength, high performance steel pipe material, is widely used in petrochemical plants. For example, in the process of oil cracking, the high temperature and high pressure environment is very strict, and GB 5310 steel pipe can meet this requirement to ensure the smooth progress of the oil cracking process. In addition, in the process of chemical reaction, GB 5310 steel pipe can also provide stable high temperature and high pressure conditions to ensure the smooth progress of chemical reaction.

2. thermal power

In the thermal power generation industry, high temperature and high pressure conditions also exist. GB 5310 Steel pipe, as a high strength, high performance steel pipe material, is widely used in the boiler pipeline of thermal power plants. For example, in the superheater, reheater and other high temperature and high pressure parts of the boiler, it is necessary to use materials that can withstand high temperature and high pressure, and GB 5310 steel pipe can meet this requirement to ensure the normal operation of the boiler. In addition, in the high pressure cylinder and other parts of the steam turbine, GB 5310 steel pipe can also provide stable high temperature and high pressure conditions to ensure the normal operation of the steam turbine.

In short, GB 5310 steel pipe, as a high-performance steel pipe material, has been widely used in petrochemical industry, thermal power generation and other fields. Its excellent performance and high reliability provide a strong guarantee for the normal operation of these industries. With the continuous progress of technology and the continuous improvement of application demand, the application prospect of GB 5310 steel pipe will be broader.