Basic Info.

Model NO.

1′′-12′′

Special Use

Cold Environment

Application

Cold Area

Inspection

SGS BV

Transport Package

as Clients Requirments

Specification

1/2" TO 24"

Trademark

DATANG

Origin

China

Production Capacity

50000 Per Year

Product Description

ASTM A335 P91 P11 P22 P5 seamless alloy steel pipe

Standard and Steel Grade:

ASTM A106/ASME SA106 Grade B, Grade C;

ASTM A179/ASME SA179;

ASTM A192/ASME SA192;

ASTM A210/ASME SA210 Grade A1, Grade C;

ASTM A333/ASME SA333 Grade 6;

ASTM A209/ASME SA209 Grade T1, T1a, T1b;

ASTM A213/ASME SA213 T2, T11, T12, T22, T91, T92;

ASTM A335/ASME SA335 P5, P9, P11, P12, P22, P91, P92;

DIN17175 St35.8, St45.8, 15Mo3, 13CrMo44, 10CrMo910;

EN10216-2 P195GH, P235GH, P265GH;

Size: OD10-168mm X WT1-18mm

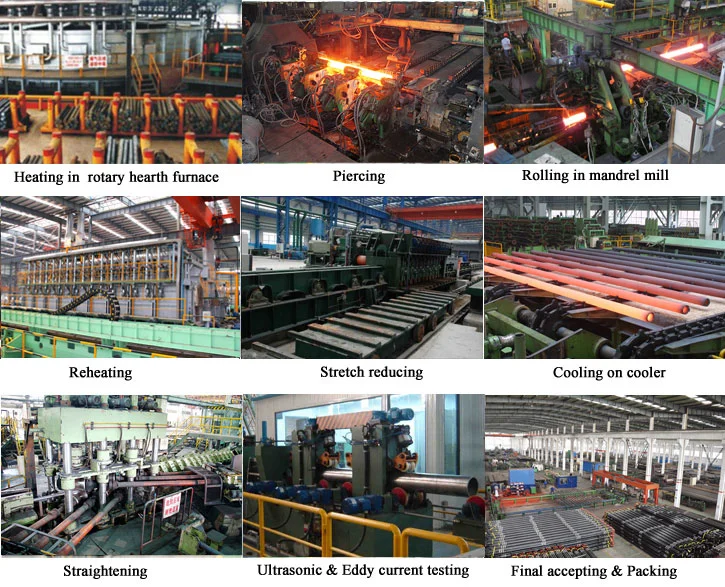

Manufacturing Method: Cold Drawn, Hot Rolled.

Application: For manufacturing boiler, reheater, superheater, heat exchanger, condenser, etc.

| item | value |

| Plac of Origin | China |

| Brand Name | Cangzhou Datang |

| Application | Fluid Pipe, Boiler Pipe, Drill Pipe, Hydraulic Pipe, Gas Pipe, OIL PIPE, Chemical Fertilizer Pipe, Structure Pipe |

| Section Shape | Round |

| | 32mm - 550mm |

| Special Pipe | API Pipe, EMT Pipe, Thick Wall Pipe |

| Thickness | 2.7mm-75mm |

| Standard | ASTM |

| Length | 12M, 6m |

| Certificate | BIS, GS, ISO9001 |

| Grade | 4130 |

| Surface Treatment | Cold Rolled |

| Tolerance | ±5% |

| Processing Service | Welding, Punching, Cutting, Bending, Decoiling |

| Oiled or Non-oiled | Non-oiled |

| Invoicing | by actual weight |

| Delivery Time | 8-14 days |

| Length | 3-12m |

| Product name | Hot Rolled Seamless Pipes |

| Thickness | 1 - 60 Mm |

| Payment terms | 30%TT Advance + 70% Balance |

| MOQ | 1 Ton |

| Surface | Bright |

| Type | Seamless Round Steel Pipe |

| Technique | Hot Rolled Cold Drawn |

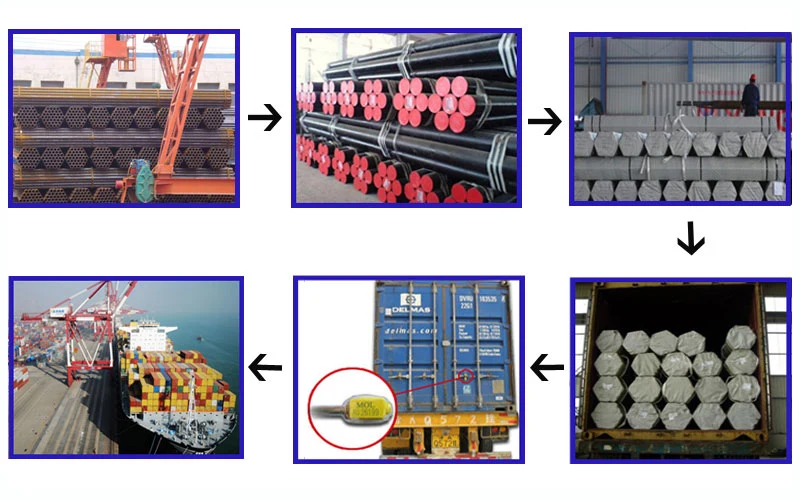

| Packing | STANDARD PACKING |

All power devices operate at high efficiencies required quality steel tubes, to guarantee their safe and long term operation. These Tubes are called as Boiler Tubes

Boiler Tubes are specially manufactured to withstand high pressure and temperature. Boiler tubes are used in energy type equipments like steam pipeline, boilers, super heaters etc.

Boiler Tubes are metal tubes located inside of boilers that heat water in order to produce steam. There are two major types of tube boilers: water-tube boilers and fire-tube boilers.

Boiler tubing is used in these industries:

Steam Boilers

Fossil Fuel Plants

Heat Exchangers

Electric Power Plants

Cogeneration Facilities

Air Preheater Unit

Waste Heat Plants

Power Generation

Economiser etc

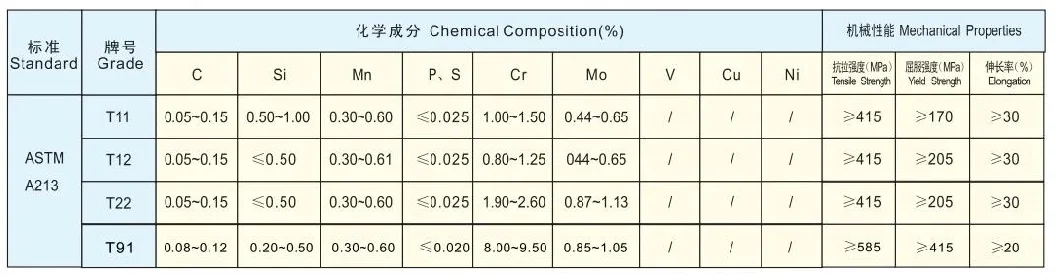

Chemical Composition&Mechanical Properties

SA179/SA192 CHEMICAL AND MECHANICAL COMPONENT:

| ASTM A179/(ASME SA179) | |

| Seamless Cold Drawn Low Carbon Steel Heat Exchanger And Conderser Tubes | |

| Application: | For tubular heat exchangers,condensers,and similar heat transfer apparatus. |

| Size(mm): | O.D.:6.0~114.0 W.T.:1~15 L:max 12000 |

Grade and Chemical Composition (%)

| Chemical Composition | C | Mn | P≤ | S≤ | Si≤ |

| 0.06-0.18 | 0.27-0.63 | 0.035 | 0.035 | 0.25 |

Tolerance(SA-450/SA-450M):

| OD In (mm) | + | - | WT In(mm) | + | - |

| <1(25.4) | 0.10 | 0.10 | ≤1.1/2(38.1) | 20% | 0 |

| 1~1.1/2(25.4~38.1) | 0.15 | 0.15 | >1.1/2(38.1) | 22% | 0 |

| >1.1/2~<2(38.1~50.8) | 0.20 | 0.20 | |||

| 2~<2.1/2(50.8~63.5) | 0.25 | 0.25 | |||

| 2.1/2~<3(63.5~76.2) | 0.30 | 0.30 | |||

| 3~4(76.2~101.6) | 0.38 | 0.38 | |||

| >4~7.1/2(101.6~190.5) | 0.38 | 0.64 | |||

| >7.1/2~9(190.5~228.6) | 0.38 | 1.14 |

ASTM A192/A192M-02 | |

| Seamless Carbon Steel Bolier Tubes for High-Pressure | |

| Application: | For seamless carbon steel bolier and superheater tubes for high-pressure service |

| Size(mm): | O.D.:6.0~114.0 W.T.:1~15 L:max 12000 |

Grade and Chemical Composition (%)

| Chemical Composition | C | Mn | P≤ | S≤ | Si≤ |

| 0.06-0.18 | 0.27-0.63 | 0.035 | 0.035 | 0.25 |

Tolerance(SA-450/SA-450M):

| OD In (mm) | + | - | WT In(mm) | + | - |

| <1(25.4) | 0.10 | 0.10 | ≤1.1/2(38.1) | 20% | 0 |

| 1~1.1/2(25.4~38.1) | 0.15 | 0.15 | >1.1/2(38.1) | 22% | 0 |

| >1.1/2~<2(38.1~50.8) | 0.20 | 0.20 | |||

| 2~<2.1/2(50.8~63.5) | 0.25 | 0.25 | |||

| 2.1/2~<3(63.5~76.2) | 0.30 | 0.30 | |||

| 3~4(76.2~101.6) | 0.38 | 0.38 | |||

| >4~7.1/2(101.6~190.5) | 0.38 | 0.64 | |||

| >7.1/2~9(190.5~228.6) | 0.38 | 1.14 |

Product Image