- Overview

- Product Description

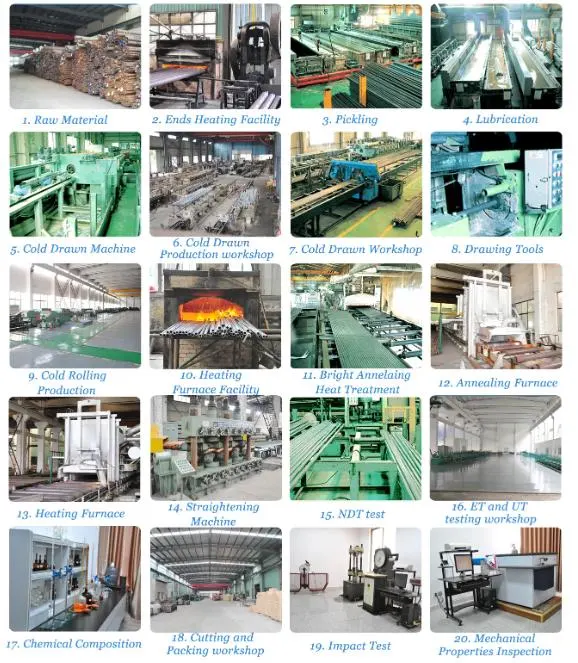

- Detailed Photos

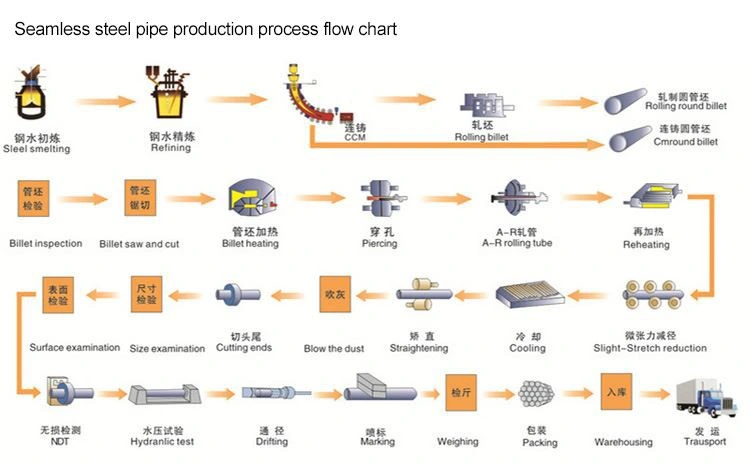

- Production process

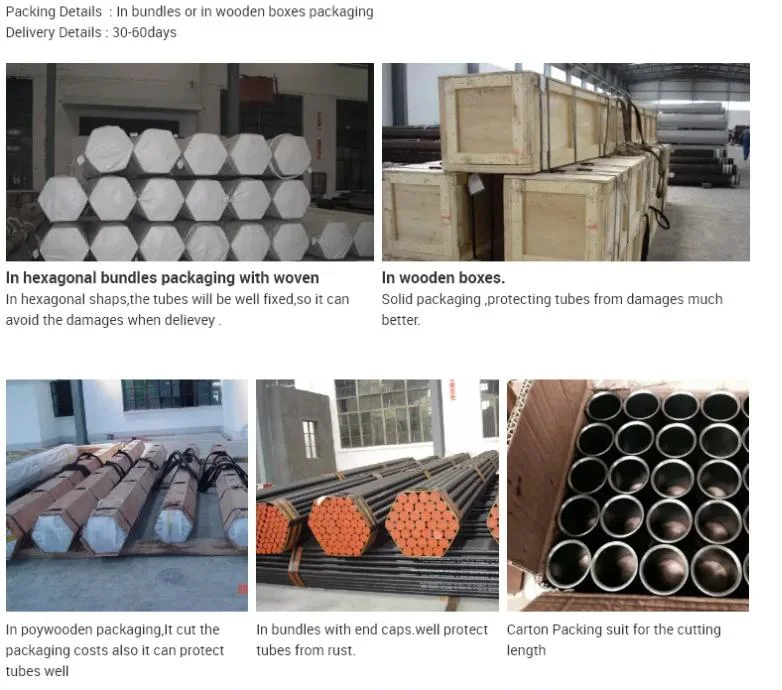

- Packaging & Shipping

- Our Advantages

- FAQ

Basic Info.

Product Description

Alloy Steel is steel that is alloyed with a variety of elements in total amounts between 1.0% and 50% by weight to improve its mechanical properties. Alloy steels are broken down into two groups: low-alloy steels and high-alloy steels. The difference between the two is somewhat arbitrary: Smith and Hashemi define the difference at 4.0%, while Degarmo, et al., define it at 8.0%.[1][2] Most commonly, the phrase "Alloy Steel " refers to low-alloy steels.

Strictly speaking, every steel is an alloy, but not all steels are called "alloy steels". The simplest steels are iron (Fe) alloyed with carbon (C) (about 0.1% to 1%, depending on type). However, the term "Alloy Steel " is the standard term referring to steels with other alloying elements added deliberately in addition to the carbon. Common alloyants include manganese (the most common one), nickel, chromium, molybdenum, vanadium, silicon, and boron. Less common alloyants include aluminum, cobalt, copper, cerium, niobium, titanium, tungsten, tin, zinc, lead and zirconium.

ASTM A213 T9 Tube is made up of a low carbon alloy steel that is suitable for high heat and high pressure applications like the chemical, power generation, petroleum and oil and gas industrial applications. The ASTM A213 T9 Tube is also used in the water supply, metallurgy, construction and ship building applications which require strong material. Multi Metals (India) is a leading manufacturer and supplier of the A213 T9 Material made products in different dimensions and shapes.

The outer diameter of the tubes ranges from 6.35mm to 101.6mm and the wall thickness of the tubes range from 1mm to 12mm. The specification ASTM A213 covers the tubes for pressure vessel class applications. The schedules of the A213 T9 Tubing range from sch40 through XXS and all schedules. The tubes are all made in seamless conditions with varying lengths up to 12m. The ASTM A213 Gr T9 Tube different end types to fit in different applications such as the plain end, beveled end and threaded ends.

The forms of the tubes vary as round, square, rectangular or hydraulic. There are carbon, chromium, manganese, molybdenum, phosphorus, sulfur and silicon in the composition. The 8% chromium composition in the Asme Sa213 T9 Tube gives it 415MPa minimum tensile strength, 205MPa minimum yield strength and 179 HB max hardness. Please feel free to contact us for more information on the ASTM A213 T9 Alloy Steel Seamless Tube and other products along with the prices.

ASTM A 1016/A 1016M Specification for General Requirements for Ferritic Alloy Steel, Austenitic Alloy Steel, and Stain- less Steel Tubes

Chemical Composition:

| Chemical Components (%) | ||||||||||||

| Grade | C | Mn | P | S | Si | Cr | Mo | V | Nb | N | Al | others |

| T9 | 0.15 | 0.30-0.60 | ≤0.025 | ≤0.025 | 0.25-1.0 | 8.0-10.0 | 0.90-1.10 | |||||

Heat Treatment Requirements:

| Grade | UNS Number | Heat Treat Type | Austenitizing / Solutioning Temperature, min or range ºF (ºC) | Subcritical Annealing or Tempering Temperature, Min or range ºF (ºC) |

| T9 | K50400 | full or isothermal anneal normalize and temper | … | 1250 (675) |

Tensile Requirements and Hardness:

| Mechanical properties | ||||

| Grade | Tensile | Yield | Elongation | Hardness |

| Strength (Mpa) | Strength (Mpa) | (%) | ||

| T9 | ≥415 | ≥205 | ≥30 | ≤89HRB |

Our company was established in 2012, is a comprehensive company integrating industry and trade. The company has successively won the honorary titles of provincial integrity enterprise and municipal excellent enterprise. We are mainly engaged in various metal related products. Such as pipes, pipe fittings, rods, coils, profiles, medium and heavy plates, narrow strips and other types of materials. The warehouse has a variety of products of different specifications and materials, and the capacity is maintained at 30,000-50,000 tons/month. Products are widely used in petroleum, chemical, electric power, coal, machinery, high and low pressure boiler tubes, hydraulic props, ships and other industries. We make full use of the advantages of self-operated export rights and enter the international market. Our customers are located in South Korea, Canada, Iran, Pakistan, Indonesia, Vietnam, South America and other countries, and we have offices in Indonesia and Vietnam. The quality of our products is enjoyed at home and abroad. high reputation. We adhere to the business philosophy of "integrity service, win-win cooperation, customer first", and provide one-stop steel solutions for global customers. Welcome friends from all over the world to visit our company. We are looking forward to establishing business relationships and personal friendships with you.

Q:How do you control quality?

A:Mill test certification is supplied with shipment,third party inspection is avaliable.

Q:What are the advantages of your company?

A:We have many professionals,technical personnel,more competitive prices and best after-sales service than other stainless steel companies

Q:How many coutries you already exported?

A:Exported to more than 50 countries mainly from Arab, Kuwait, Egypt, Turkey, Jordan, Brazil, India, Indonesia, Korea, etc

Q:Can you provide sample?

A:Small sample in store and can provide the sample for free.Customized samples will take about 5-7days

Q:Why should you buy from us not from other suppliers?

A:Diversified products, direct supply from manufacturer.

Q:What is your terms of payment ?

A:we accept T/T ,L/C ,D/A,D/P, Western union, paypal ,The payment method can be negotiated by both parties according to the actual situation.

Please Please leave your enquiry in the message box at the bottom of the product page and click SEND, we will contact you as soon as possible!