- Overview

- Packaging & Shipping

Basic Info.

Model NO.

400/k-500

Special Use

Abrasive Resistance/Corrosion Resistance

Application

Energy/Chemical/Medical/Aviation etc

Thickness

0.3~60mm/Customized

Length

3,6,9,12m/Customized

Condition

New

Place of Origin

Wenzhou,Zhejiang

Product Name

Monel Copper Nickel Alloy Tube

Brand Name

Langzhi

Certificate

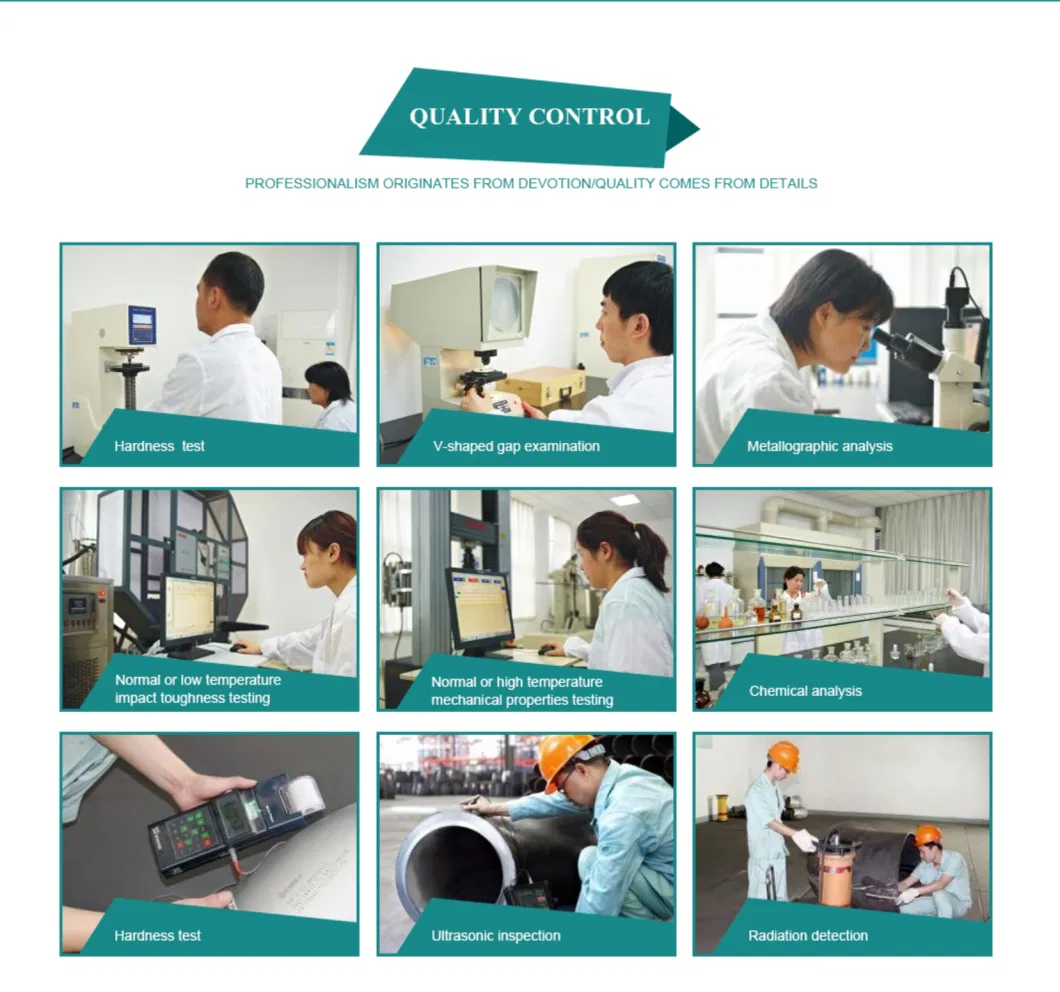

ISO9001/ISO14001

Transport Package

Wooden Case/Customized

Specification

8~1016mm/Customized

Trademark

Langzhi

Origin

China

HS Code

7507120000

Production Capacity

50000+PC/Year

Product Description

Langzhi is a professional manufacturer of specialty metal/alloy tube & pipe products.

We have a wide range of standards and specifications, and also accept customized specifications.

Including titanium, hastelloy, nickel alloy, super duplex stainless etc high corrosion resistance materials, which apply for those high corrosion or special fields such as petrochemical, metallurgy, mineral, water resources, medical industry etc.

Langzhi Regular Specification

| Thickness (mm) | 0.3 | 0.4 | 0.5 | 0.6 | 0.7 | 0.8 | 0.9 | 1 | 1.2 | 1.5 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 10 |

| Outside Diameter (mm) | ||||||||||||||||||

| Φ9.52 | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | / | / | / | / | / | / | / | / |

| Φ12.7 | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | / | / | / | / | / | / | / | / |

| Φ15.88 | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | / | / | / | / | / | / | / | / |

| Φ19.1 | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | / | / | / | / | / | / | / |

| Φ22 | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | / | / | / | / | / | / | / |

| Φ25.4 | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | / | / | / | / | / | / | / |

| Φ31.8 | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | / | / | / | / | / | / | / |

| Φ38.1 | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | / | / | / | / | / | / | / |

| Φ45 | / | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | / | / | / | / | / | / | / |

| Φ50.8 | / | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | / | / | / | / | / | / | / |

| Φ57 | / | / | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | / | / | / | / | / | / |

| Φ60.3 | / | / | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | / | / | / | / | / | / |

| Φ63.5 | / | / | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | / | / | / | / | / | / |

| Φ76.2 | / | / | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | / | / | / | / | / | / |

| Φ88.9 | / | / | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | / | / | / | / | / |

| Φ101.6 | / | / | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | / | / | / | / | / |

| Φ108 | / | / | / | / | / | √ | √ | √ | √ | √ | √ | √ | √ | / | / | / | / | / |

| Φ114.3 | / | / | / | / | / | √ | √ | √ | √ | √ | √ | √ | √ | / | / | / | / | / |

| Φ127 | / | / | / | / | / | √ | √ | √ | √ | √ | √ | √ | √ | / | / | / | / | / |

| Φ133 | / | / | / | / | / | √ | √ | √ | √ | √ | √ | √ | √ | / | / | / | / | / |

| Φ141 | / | / | / | / | / | / | / | √ | √ | √ | √ | √ | √ | / | / | / | / | / |

| Φ159 | / | / | / | / | / | / | / | √ | √ | √ | √ | √ | √ | / | / | / | / | / |

| Φ168 | / | / | / | / | / | / | / | / | / | √ | √ | √ | √ | / | / | / | / | / |

| Φ219 | / | / | / | / | / | / | / | / | / | / | / | √ | √ | √ | √ | √ | / | / |

| Φ273 | / | / | / | / | / | / | / | / | / | / | / | √ | √ | √ | √ | √ | / | / |

| Φ325 | / | / | / | / | / | / | / | / | / | / | / | √ | √ | √ | √ | √ | √ | / |

| Φ355 | / | / | / | / | / | / | / | / | / | / | / | √ | √ | √ | √ | √ | √ | / |

| Φ377 | / | / | / | / | / | / | / | / | / | / | / | √ | √ | √ | √ | √ | √ | / |

| Φ406 | / | / | / | / | / | / | / | / | / | / | / | √ | √ | √ | √ | √ | √ | / |

| Φ426 | / | / | / | / | / | / | / | / | / | / | / | √ | √ | √ | √ | √ | √ | / |

| Grade | C | P | S | Mn | Si | Ni | Cr | Co | Cu | Fe | N | Mo | Al | W | V | Ti | Others |

| Less than | |||||||||||||||||

| Hastelloy B | 0.05 | 0.04 | 0.03 | 1 | 1 | base | <=1 | <=2.5 | - | 4~6 | - | 26-30 | - | - | 0.2-0.4 | - | - |

| UNS N10665(Hastelloy B-2) | 0.02 | 0.04 | 0.03 | 1 | 0.1 | base | <=1 | <=1 | - | <=2 | - | 26-30 | - | - | - | - | - |

| UNS N10673(Hastelloy B-3) | 0.01 | 0.03 | 0.01 | 3 | 0.1 | >=65 | 1~3 | <=3 | <=0.2 | 1~3 | - | 27-32 | <=0.5 | <=3 | <=0.2 | <=0.2 | Ni+Mo 94-98 |

| Hastelloy C | 0.08 | 0.04 | 0.03 | 1 | 1 | base | 14.5-16.5 | <=2.5 | - | 4~7 | - | 15-17 | - | 3-4.5 | <=0.35 | - | - |

| Hastelloy C-4 | 0.015 | 0.04 | 0.03 | 1 | 0.08 | base | 14-18 | <=2 | - | <=3 | - | 14-17 | - | - | - | <=0.7 | - |

| UNS N06022(Hastelloy C-22) | 0.015 | 0.02 | 0.02 | 0.5 | 0.08 | base | 20-22.5 | <=2.5 | - | 2~6 | - | 12.5-14.5 | - | 2.5-3.5 | <=0.35 | - | - |

| UNS N10276(Hastelloy C-276) | 0.01 | 0.04 | 0.03 | 1 | 0.08 | base | 14.5-16.5 | <=2.5 | - | 4~7 | - | 15-17 | - | 3-4.5 | <=0.35 | - | - |

| Hastelloy C-2000 | 0.01 | 0.025 | 0.01 | 0.5 | 0.08 | base | 22-24 | <=2 | 1.3-1.9 | <=3 | - | 15-17 | <=0.5 | - | - | - | - |

| Hastelloy G-3 | 0.015 | 0.04 | 0.03 | 1 | 1 | base | 21-23.5 | <=5 | 1.5-2.5 | 18~21 | - | 6~8 | - | <=1.5 | - | - | Nb/Ta<=0.5 |

| Hastelloy X | 0.05-0.15 | 0.025 | 0.015 | 1 | 1 | base | 20.5-23 | 0.5-2.5 | <=0.5 | 17~20 | - | 8~10 | <=0.5 | 0.2-1 | - | <=0.15 | - |